Factice spraying device for optical cable manufacturing and using method of factice spraying device

A technology of spraying device and ointment, applied in the directions of spraying device, device for coating liquid on the surface, light guide, etc., can solve the problems of increased waste and cost, pollution of ointment, extraction, etc., to reduce waste, avoid pollution, avoid intermittent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

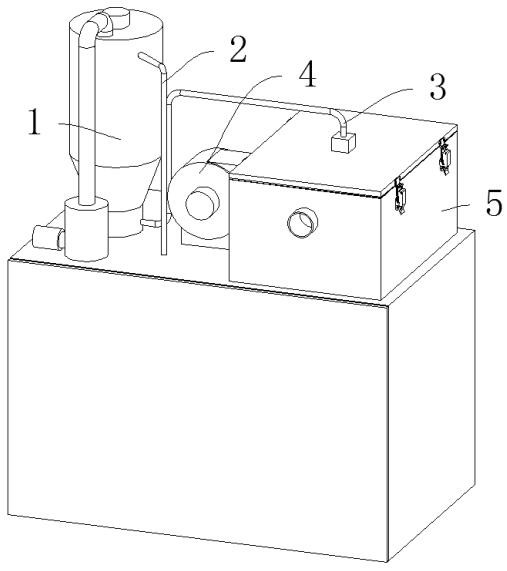

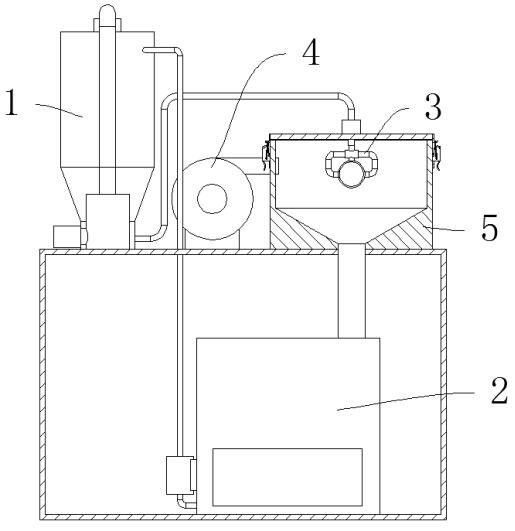

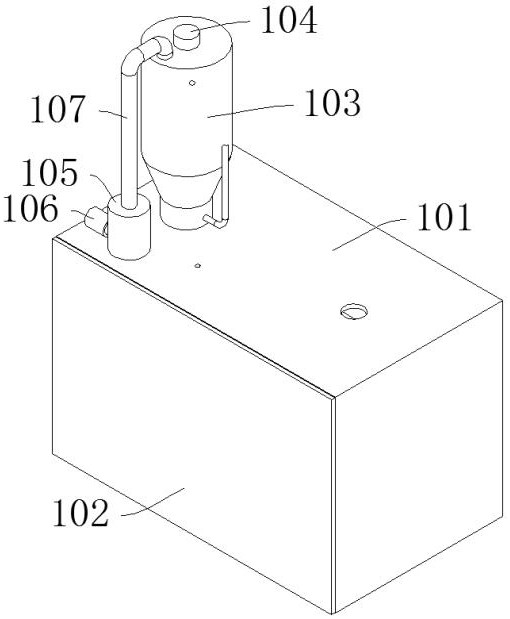

[0047] like Figure 1-Figure 7 Shown, a kind of optical cable manufacturing grease spraying device comprises the main box device 1 that is used to hold the grease, the recovery device 2 that is used for grease recovery is installed in the main box device 1, and the main box device 1 is provided with for Close the sub-box device 5 for spraying ointment, the sub-box device 5 is provided with a smearing device 3 for spraying ointment, and the side of the sub-box device 5 is provided with a wind pressure device 4 for generating negative pressure; the main box device 1 includes Main box body 101, main box cover 102 is installed in the front of main box body 101, storage tank 103 is arranged on main box body 101, sealing cover 104 is installed on the top of storage tank 103, and air pump 105 is arranged in front of storage tank 103, and air pump 105 one The first air filter cartridge 106 is installed on the side, and the air delivery pipe 107 is installed on the air pump 105; the re...

Embodiment 2

[0050] like Figure 8 As shown, the difference between embodiment 2 and embodiment 1 is that the auxiliary box device 5 includes an auxiliary box body 501, an auxiliary box cover 502 is installed on the auxiliary box body 501, and two inlet and outlet pipes 503 are symmetrically arranged on the front and rear of the auxiliary box body 501, A receiving hopper 506 is arranged in the auxiliary box 501, and a second recovery pipe 507 is arranged at the bottom of the receiving hopper 506; the auxiliary box cover 502 and the auxiliary box 501 are snap-connected, and the inlet and outlet pipes 503 and the auxiliary box 501 are welded together. The recovery pipe 507 is plugged and connected with the auxiliary box body 501 , the second recovery pipe 507 is connected with the recovery box 201 in a sealed and threaded manner, and the receiving hopper 506 and the second recovery pipe 507 are integrally formed.

[0051] The present invention also provides a method for using an ointment spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com