Pre-coating filtering system capable of continuously operating for long period

A filtration system and long-term technology, applied in the direction of filtration separation, fixed filter element filter, separation method, etc., can solve the problems such as difficult filtration accuracy requirements of filtration technology, achieve excellent filtration effect, low maintenance cost and prolong life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so as to help understand the content of the present invention. Unless otherwise specified, the terms used in the present invention are conventional terms in the industry.

[0026] The pre-coating filtration system involved in the present invention can not only be applied to oil slurry filtration, but also to other raw materials to be filtered such as paraffin filtration, coal tar filtration, and dilute ammonium sulfate liquid filtration. This embodiment only uses the pre-coating filtration system The application in catalytic cracking oil slurry is taken as an example to describe the working principle and application process of the pre-coat filter system in detail.

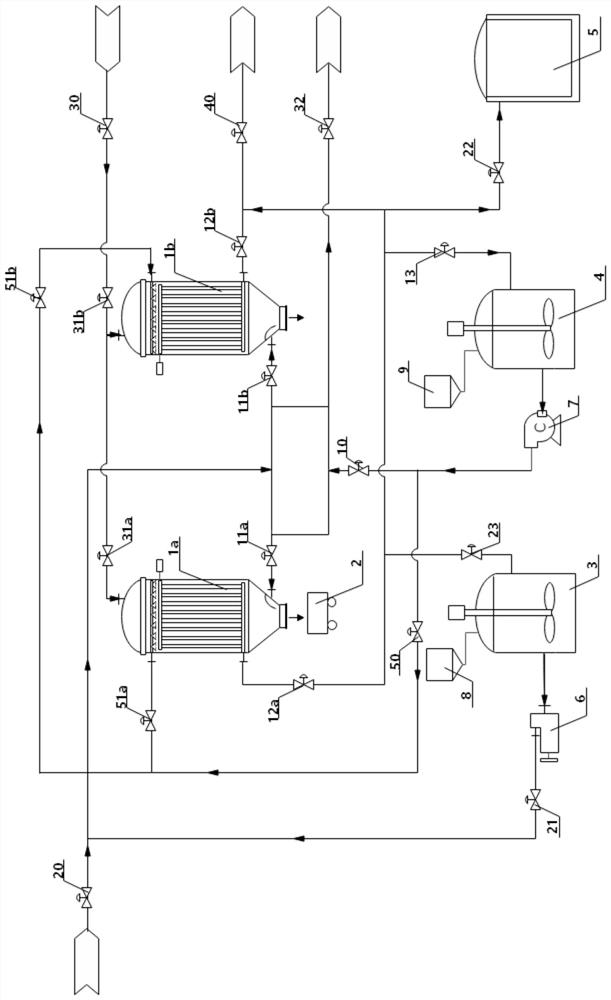

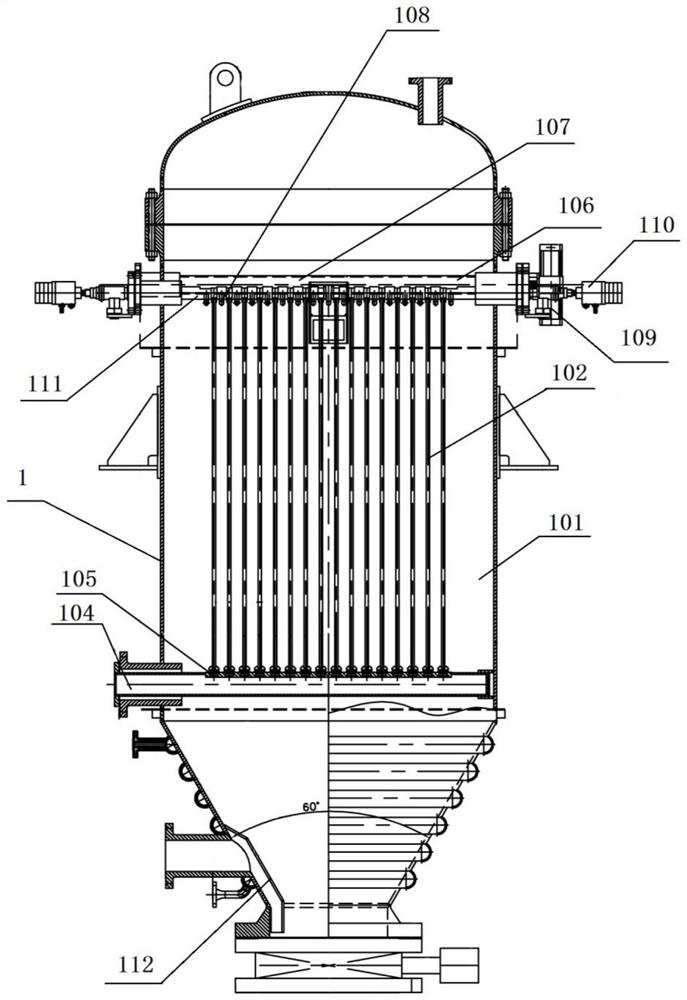

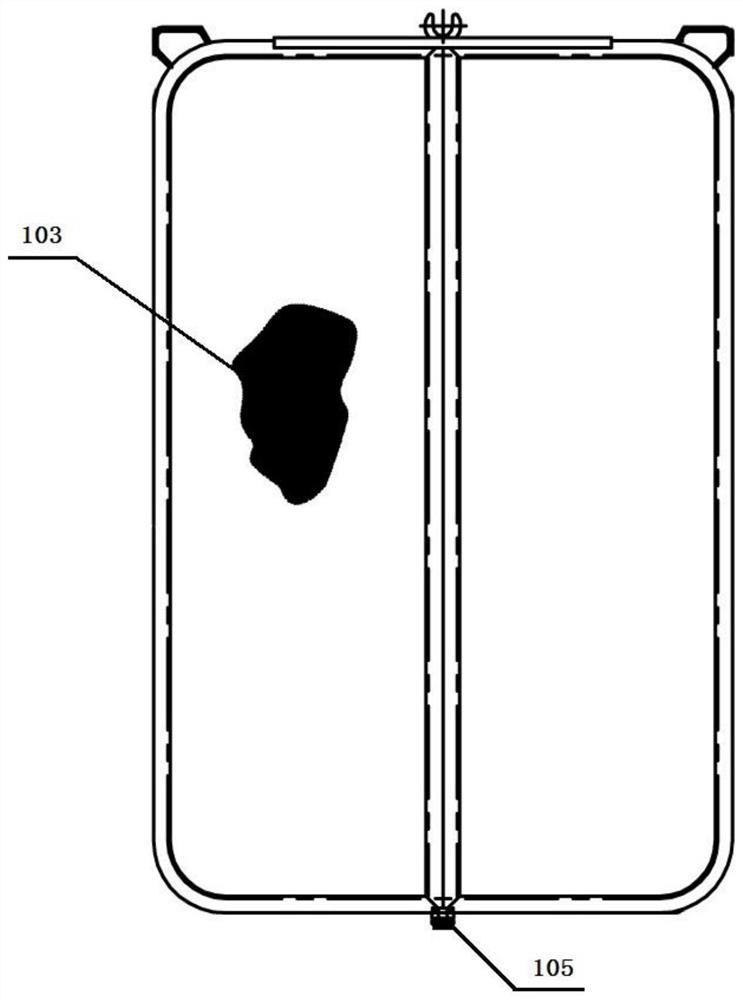

[0027] refer to Figure 1-Figure 3 , the present invention provides a long-term continuous operation of the pre-coating filtration system, which includes a pre-coating unit, an auxil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com