Asynchronous motor fault detection method based on observer

A technology for fault detection of asynchronous motors, applied in the control of generators, motor control, motor generator control, etc., can solve problems such as insufficient timeliness of fault detection, reduce maintenance time and costs, reduce unexpected changes, and prevent aggravation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

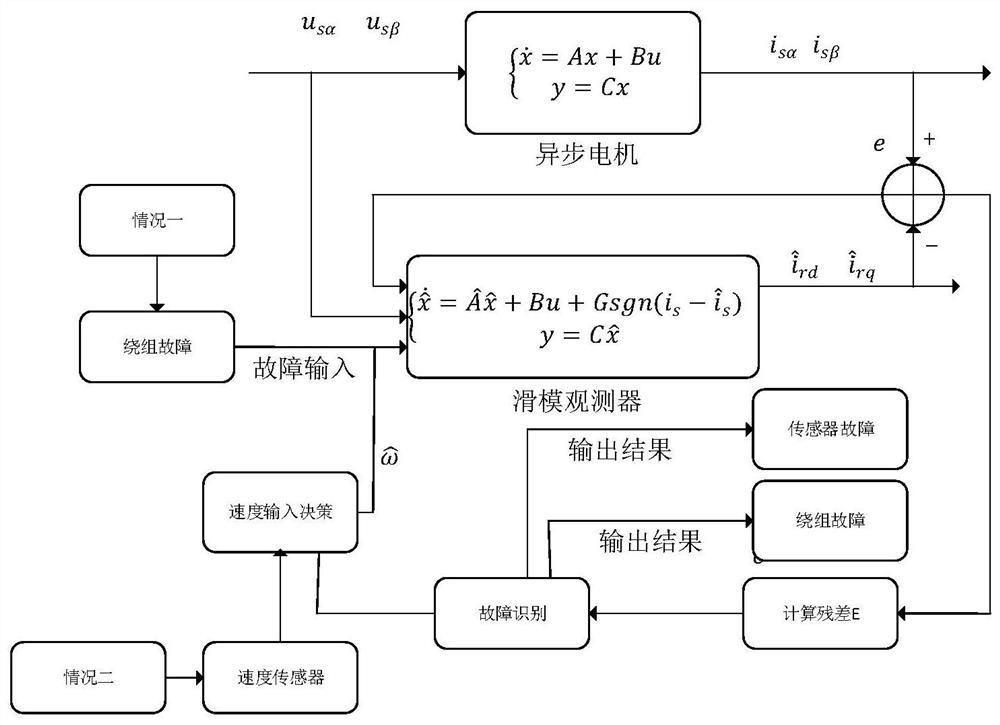

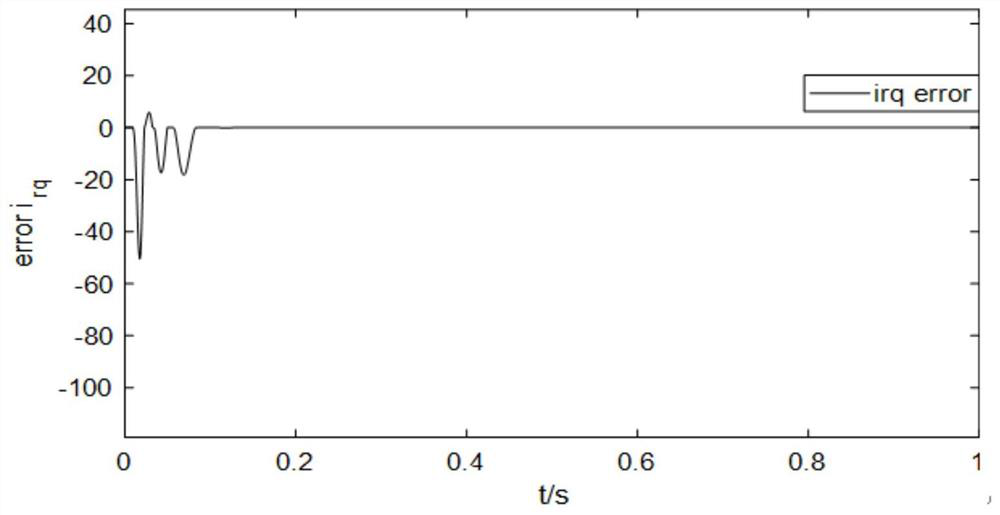

[0061] 1. When the asynchronous motor is running normally, the error curve between the actual value and the observed value of the rotor current (here, irq is used to illustrate) is as follows figure 2 . It can be seen from the error curve that the error value curve is close to 0, indicating that the asynchronous motor is in a normal working state.

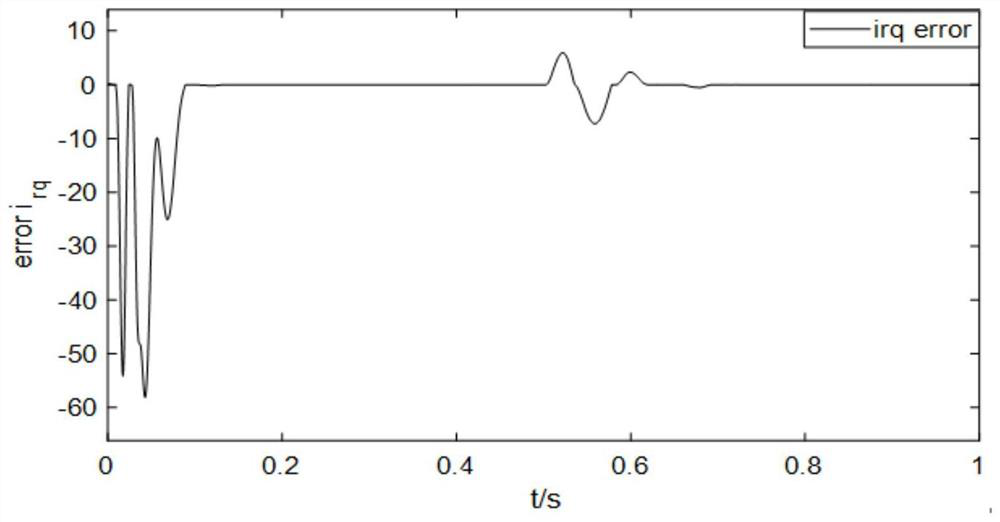

[0062] 2. When a short-circuit fault occurs between turns of the stator winding of an asynchronous motor, the error curve between the actual value and the observed value of the rotor current (here irq is used for illustration) is as follows: image 3 . When the fault is added at 0.5s, it can be seen from the error curve of the actual value of the rotor current and the observed value that the curve is stable near 0, and the curve fluctuates at 0.5s, so it can be seen that the asynchronous motor has a fault at 0.5s , so that the fault detection of the asynchronous motor is realized by the sliding mode observer.

[0063] 3. When t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com