Refrigerating machine room energy-saving optimization method and system based on chilled water and cooling water variable flow decoupling

A refrigeration machine room and optimization method technology, applied in neural learning methods, design optimization/simulation, computer-aided design, etc., can solve problems such as instability, energy-saving optimization of refrigeration room, unadjustable control equipment, unscientific control strategies, etc., to achieve Intuitive effect of the model

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

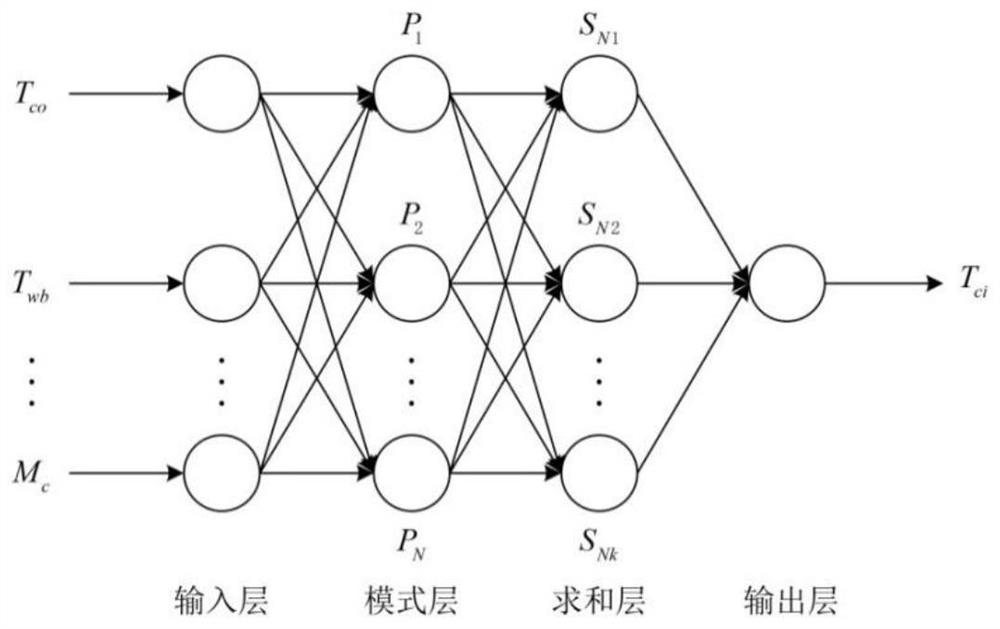

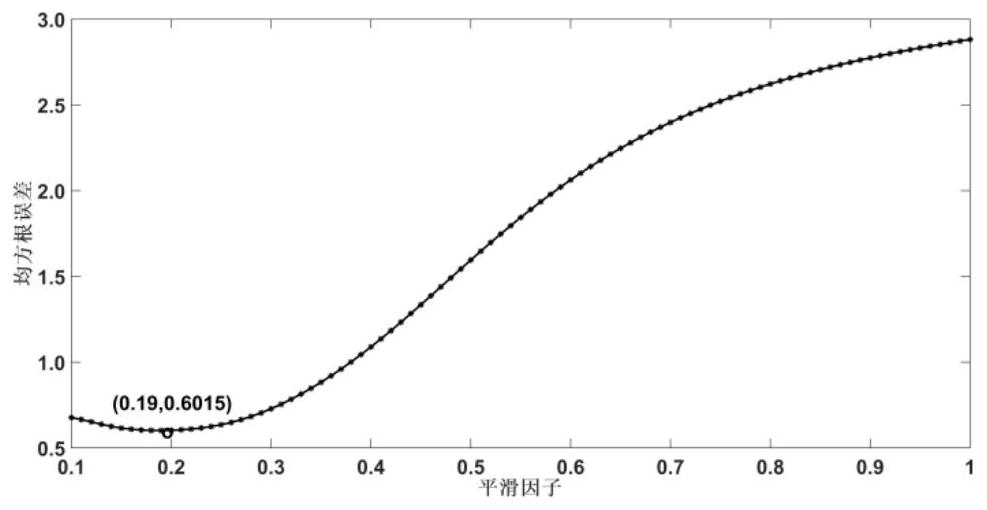

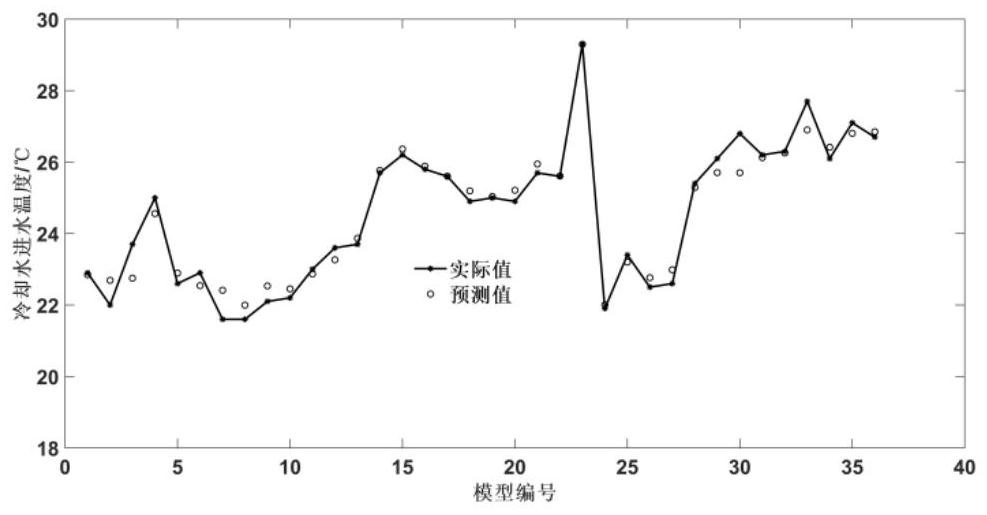

[0077] In this embodiment, a cooling water inlet temperature modeling method based on GRNN is disclosed, which provides a reliable theoretical basis for improving the energy efficiency model of chiller.

[0078] Because the cop of chiller is affected by many factors, such as partial load rate, chilled water supply and return temperature, cooling water inlet and outlet temperature, chilled water flow and cooling water flow, and there are complex interactive relationships among various influencing factors.

[0079] In order to clarify the influence degree of each operating parameter on the operating energy efficiency of the chiller, the invention uses SPSS software to analyze the correlation between the operating energy efficiency of the chiller and multiple influencing factors, and carries out the correlation analysis through Pearson correlation coefficient and bilateral significance test. The results are shown in Table 1. The correlation between the cooling water inlet temperature...

Embodiment 2

[0107] In this embodiment, the polynomial regression method is used to obtain the relationship curve between the power of the water pump and the flow, which is as follows:

[0108] Step 1. Select the expression. For variable frequency water pump, the power calculation formula under full load condition is as follows:

[0109]

[0110] η=η p · η m · η VFD (8)

[0111] Where, P pump Is the pump power, kW; ρ Is the density of the fluid, kg / M 3 ; G is gravitational acceleration, M / S 2 ; M is the volume flow of fluid, M 3 / h; H is the head of the water pump, m; η Is the total efficiency of the water pump; η p Is the pump efficiency; η m Is the motor efficiency; η VFD Is the efficiency of the frequency converter.

[0112] From the actual analysis, the variable frequency pump operates under partial load most of the time, and its power model can be expressed as a polynomial relationship with flow, and the expression is as follows:

[0113]

[0114] Where M rated Is the rated flow o...

Embodiment 3

[0117] This example is the application of variable flow decoupling control strategy of chilled water and cooling water on TRNSYS simulation platform. Combined with the research object of the comprehensive office building of the invention, the load characteristics and pressure loss of each loop of the air conditioning cold source system are quite different, and the rooms on each floor need to have personalized settings and other characteristics. Selecting the differential pressure control of the fixed supply and return water main pipe as the variable flow control mode of chilled water can meet the above requirements. On the cooling water variable flow side, since most of the operation of the air conditioning cold source system is under partial load, the constant temperature difference control method is adopted, which is equivalent to the proportional change of the cooling water flow with the load. The control method is simple and effective. Therefore, the constant temperature diffe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com