Additive composition and preparation method thereof, linear low-density polyethylene composition and preparation method thereof, and polyethylene cast packaging film

A linear low-density, composite technology, applied in the direction of chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of small precipitates on the surface of the film layer, poor opening performance, low haze, etc., to achieve The effect of smooth film, less precipitates and low haze

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

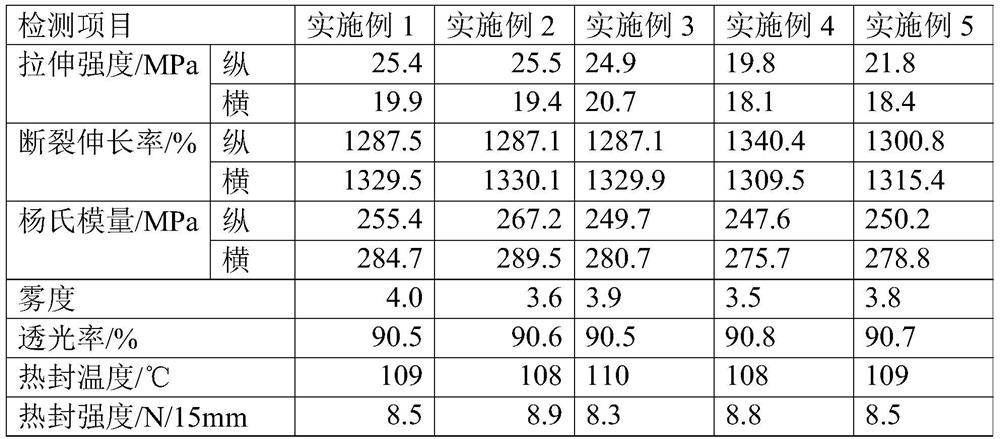

Examples

Embodiment 1

[0054] This embodiment is used to prepare polyethylene cast packaging film, and concrete steps are as follows:

[0055] (1) preparation auxiliary composition:

[0056] Based on the total weight of the additive composition, the antioxidant 1010 with a content of 18% by weight, the antioxidant 168 with a content of 18% by weight, the zinc stearate with a content of 5% by weight, and the hydrotalcite with a content of 8% by weight (DHT-4A, particle size 0.4 μm), silicon dioxide (AB905, particle size 5 μm) with a content of 48% by weight and antistatic agent 1800 with a content of 3% by weight were mixed to obtain an additive composition.

[0057] (2) Preparation of linear low density polyethylene composition:

[0058] Prepared by the Unipol gas phase process, the melt index is 4.0g / 10min and the density is 0.927g / cm at 2.16kg load and 190°C 3 linear low density polyethylene;

[0059] Based on the total weight of the linear low-density polyethylene composition, the auxiliary ag...

Embodiment 2

[0067] This embodiment is used to prepare polyethylene cast packaging film, and concrete steps are as follows:

[0068] (1) preparation auxiliary composition:

[0069] Based on the total weight of the additive composition, the antioxidant 1010 with a content of 15% by weight, the antioxidant 168 with a content of 20% by weight, the zinc stearate with a content of 5% by weight, and the hydrotalcite with a content of 10% by weight (particle size: 0.7 μm), silicon dioxide (particle size: 8 μm) with a content of 48% by weight and antistatic agent 1800 with a content of 2% by weight were mixed to obtain an additive composition.

[0070] (2) Preparation of linear low density polyethylene composition:

[0071] Prepared by the Unipol gas phase process, the melt index is 3.5g / 10min and the density is 0.925g / cm at 2.16kg load and 190°C 3 linear low density polyethylene;

[0072] Based on the total weight of the linear low density polyethylene composition, the auxiliary agent composit...

Embodiment 3

[0080] This embodiment is used to prepare polyethylene cast packaging film, and concrete steps are as follows:

[0081] (1) preparation auxiliary composition:

[0082]Based on the total weight of the additive composition, the antioxidant 1010 with a content of 20% by weight, the antioxidant 168 with a content of 15% by weight, the zinc stearate with a content of 5% by weight, and the hydrotalcite with a content of 15% by weight (particle size: 0.5 μm), silicon dioxide (particle size: 8 μm) with a content of 43% by weight and antistatic agent 1800 with a content of 2% by weight were mixed to obtain an additive composition.

[0083] (2) Preparation of linear low density polyethylene composition:

[0084] Prepared by the Unipol gas phase process, the melt index is 3.0g / ml and the density is 0.925g / cm at 2.16kg load and 190°C 3 linear low density polyethylene;

[0085] Based on the total weight of the linear low density polyethylene composition, the auxiliary agent composition ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com