Low-alkalinity fertilizer efficiency slow-release ceramsite vegetation concrete and preparation method thereof

A technology of planting raw concrete and slow-release type, applied in the field of concrete, can solve the problems of improving the water and fertilizer retention performance of planting materials, waste of resources, and difficult to mix evenly, etc. Durable, plant-compatible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

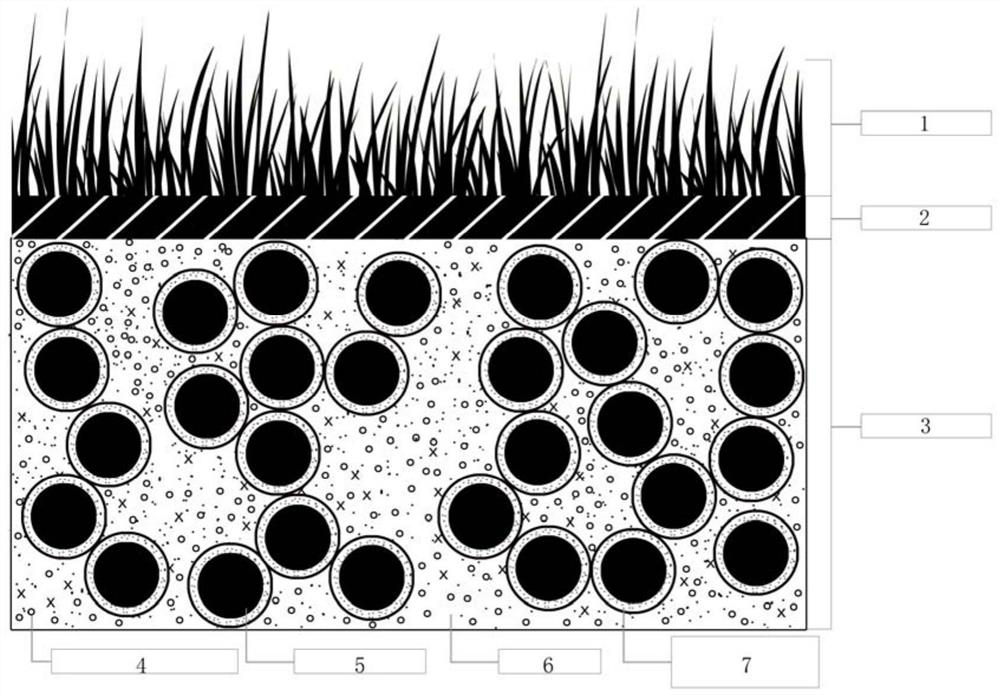

[0050] The ecological concrete formula 1 in Table 4 is according to step 1: Stirring: first, stir the evenly mixed low-alkalinity high-belite sulphoaluminate cement, fly ash, silica fume and ceramsite for 90 seconds, and then add 70% of Water and water reducer, stir for 90s, and finally add the remaining water and water reducer and stir for 120s, the total stirring time is 300s;

[0051] Step 2: Forming and maintenance: After adjusting the concrete slump to the design requirement of 250mm, use manual pouring, vibration forming, and the vibration time is 10s. The temperature is 20±2°C, and the relative humidity is above 95% for curing, and the curing time is not less than 7 days;

[0052] Step 3: Sowing: Mix the filling materials (soil and slow-release full-nutrient fertilizer, etc.) evenly, and then use the grouting method to fill the pores of the ceramsite concrete, and then mix the plant seeds with the surface layer of guest soil evenly, and place them in the ceramsite concr...

Embodiment 2

[0058] The ecological concrete formula 2 in Table 5 is followed by step 1: Stirring: first, stir the evenly mixed low-alkalinity high-belite sulfoaluminate cement, fly ash, silica fume and ceramsite for 60 seconds, and then add 70% of Water and superplasticizer, stir for 60s, and finally add the remaining water and superplasticizer and stir for 90s, the total stirring time is 210s;

[0059] Step 2: Forming and curing: After the concrete slump is adjusted to the design requirement of 100mm, manual pouring and vibration forming are used for 5 seconds. The temperature is 20±2°C, and the relative humidity is above 95% for curing, and the curing time is not less than 7 days;

[0060] Step 3: Sowing: Mix the filling material (soil and slow-release full-nutrient fertilizer, note: not including fly ash and silica fume), and then use the grouting method to fill the pores of the ceramsite concrete, and then mix the plant seeds with the surface The foreign soil is mixed evenly, and a la...

Embodiment 3

[0065] According to the ecological concrete formula 3 in Table 6, follow step 1: stirring: first, stir the evenly mixed low alkalinity high belite sulfoaluminate cement, fly ash, silica fume and ceramsite for 70 seconds, then add 70% of Water and superplasticizer, stir for 70s, and finally add the remaining water and superplasticizer and stir for 100s, the total stirring time is 240s;

[0066] Step 2: Forming and maintenance: After adjusting the concrete slump required by the design to 160mm, use manual pouring, vibration forming, and the vibration time is 6s. The temperature is 20±2°C, and the relative humidity is above 95% for curing, and the curing time is not less than 7 days;

[0067] Step 3: Sowing: Mix the filling materials (soil and slow-release full-nutrient fertilizer, etc.) evenly, and then use the grouting method to fill the pores of the ceramsite concrete, and then mix the plant seeds with the surface layer of guest soil evenly, and place them in the ceramsite con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| osmotic coefficient | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com