Bagging and packaging equipment for automatic production line

An automatic production line and packaging equipment technology, applied in packaging, transportation packaging, packaging protection, etc., can solve the problems of different application ranges of packaging equipment, affecting artificial health, irregular deformation of bag openings, etc., to reduce manual steps and move stably , the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The preferred embodiments of the present invention will be described in further detail in conjunction with the accompanying drawings.

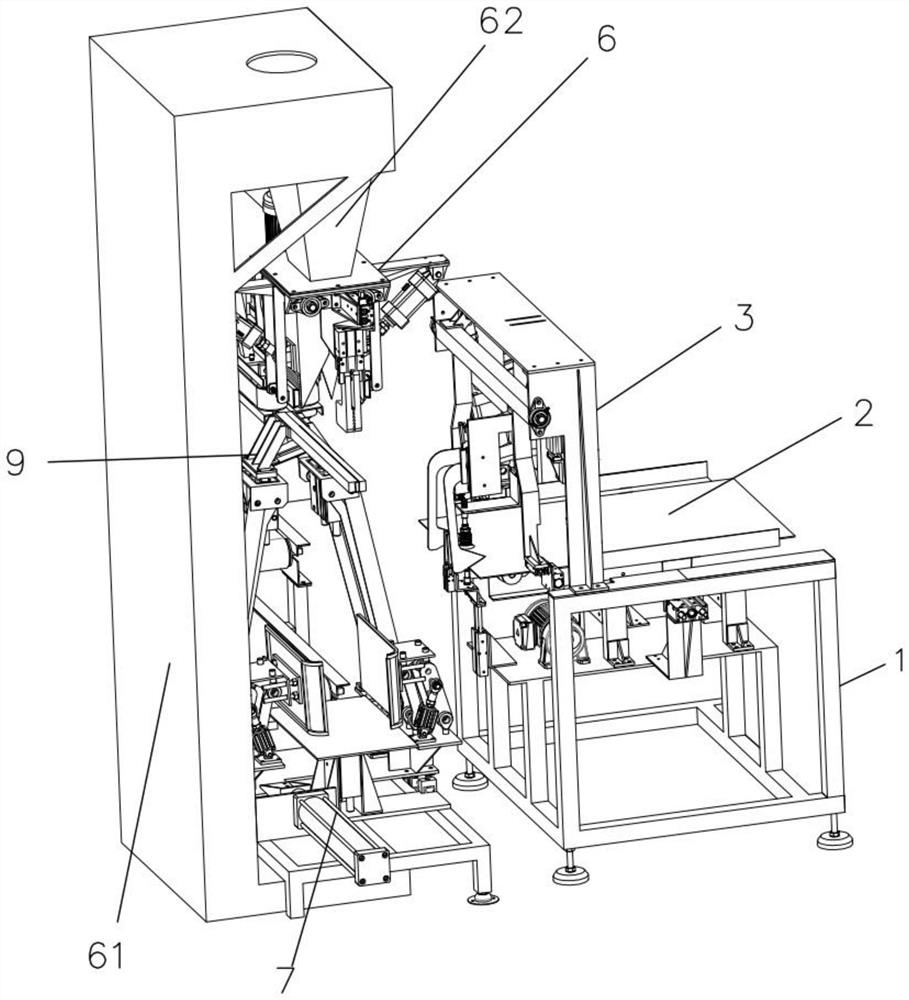

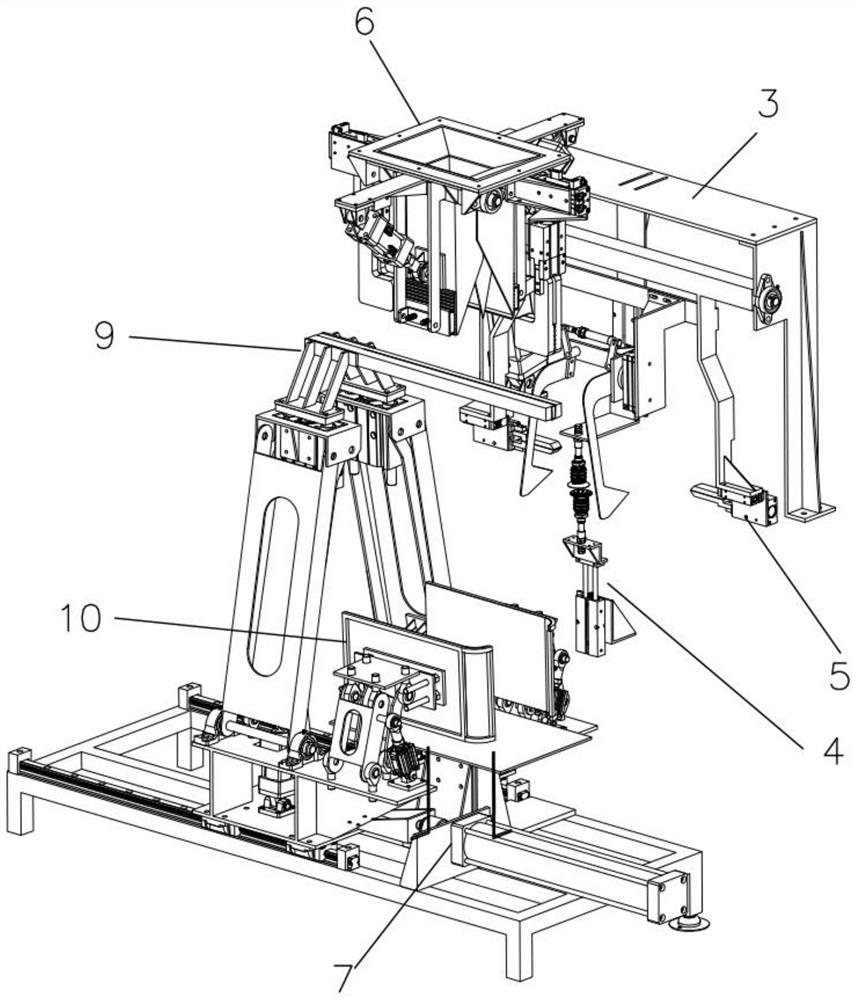

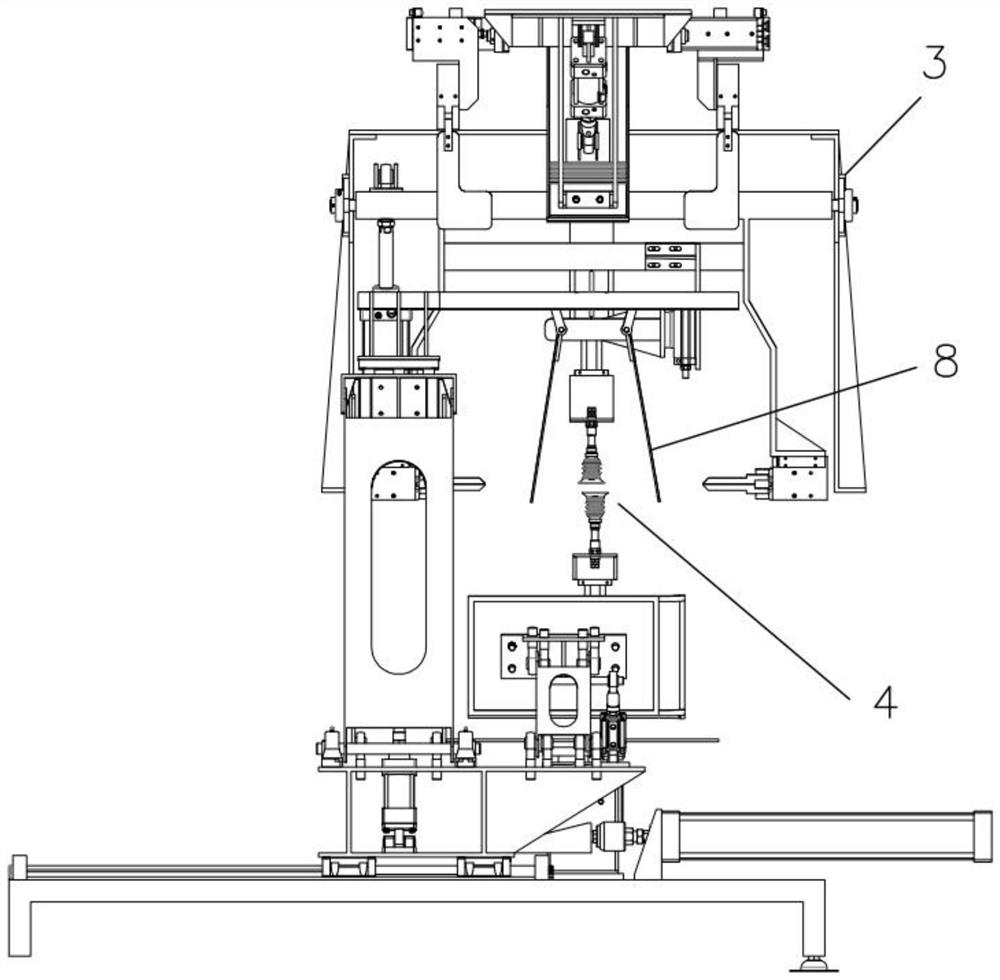

[0034] like Figure 1-12 The bagging and packaging equipment used on an automated production line includes a frame 1, a PLC controller, a conveying device 2, a rotating device 3, an auxiliary bag opening device 4, a bag clamping device 5, and a feeding clip The bag device 6 and the bag-holding transplanting device, the upper side of the frame 1 is located above the conveying device 2, and the rotating device 3 and the bag mouth auxiliary suction opening device 4 are correspondingly installed, and the bag-holding transplanting device is located below the material clamping bag device 6, The bag clamping device 5 is installed at the bottom of the rotating device 3, and the bag opening auxiliary suction device 4 sucks and controls the top of the bag. The bag clamping device 5 clamps both sides of the bag, and the bag is rotated 90 degrees b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com