Piling device and method for construction of underwater reinforced concrete precast slab pile

A technology of reinforced concrete and piling equipment, applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of high technical difficulty, high construction difficulty, high cost, etc., reduce construction cost and construction time, facilitate alignment, reduce The effect of small installation gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

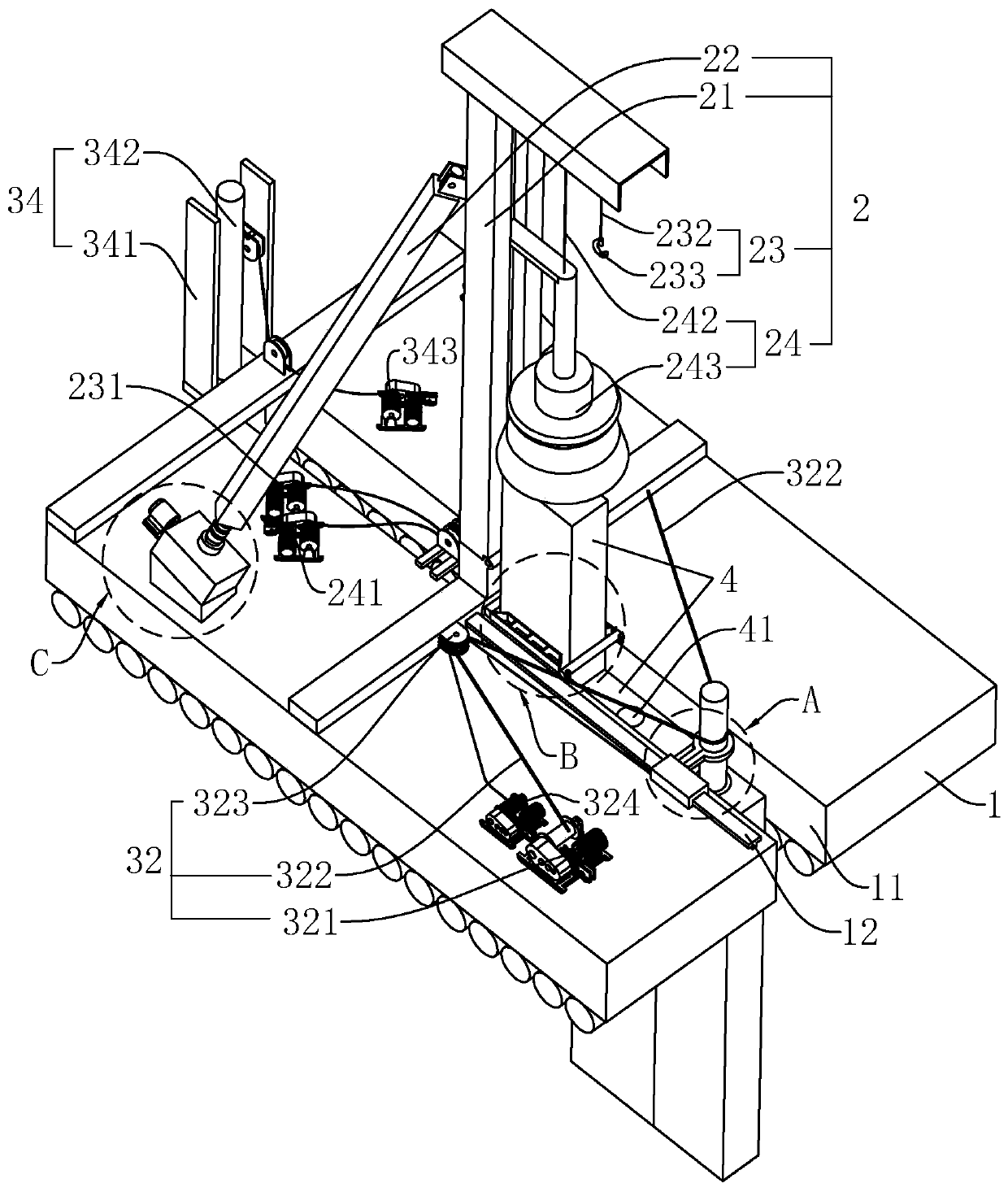

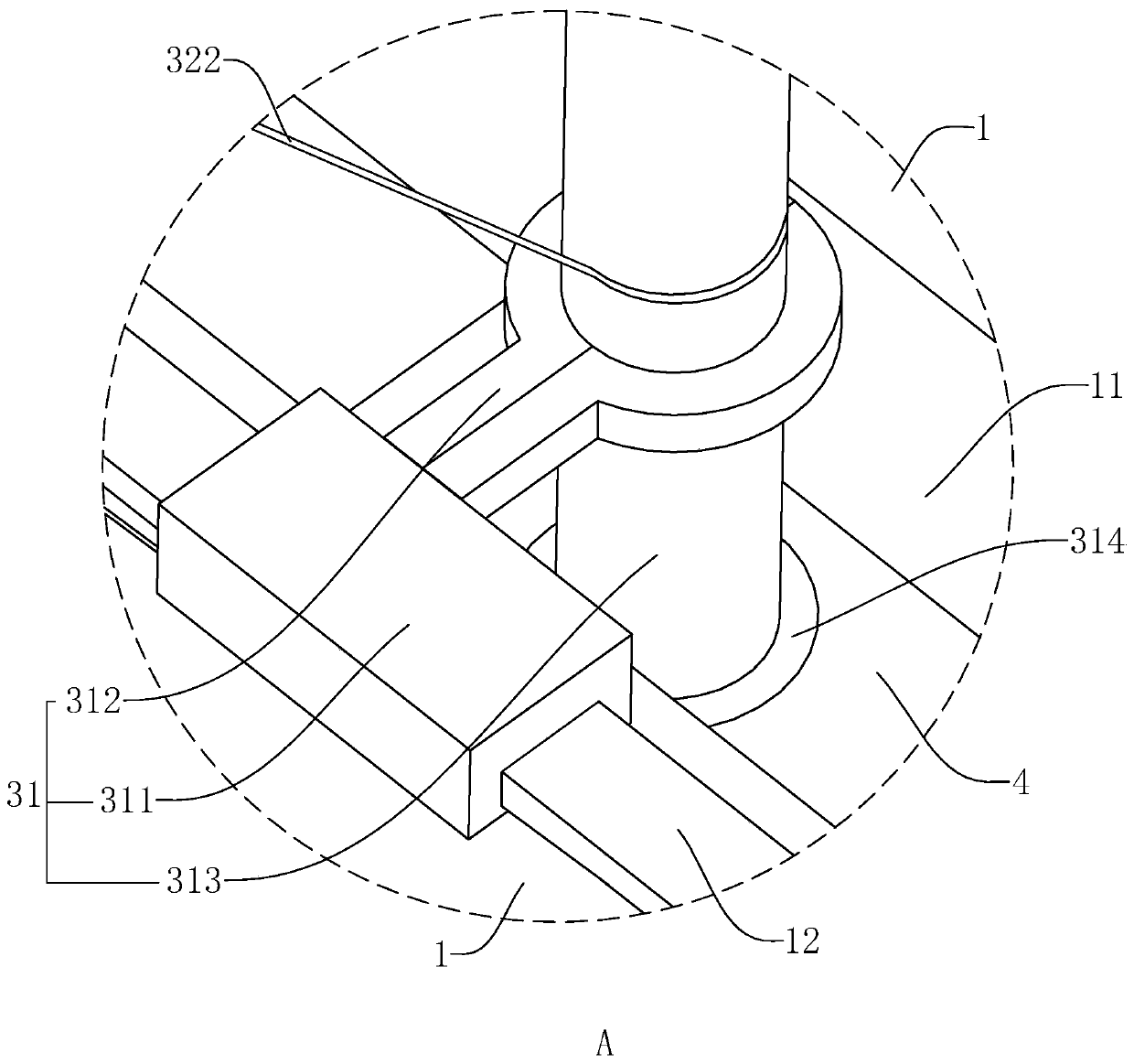

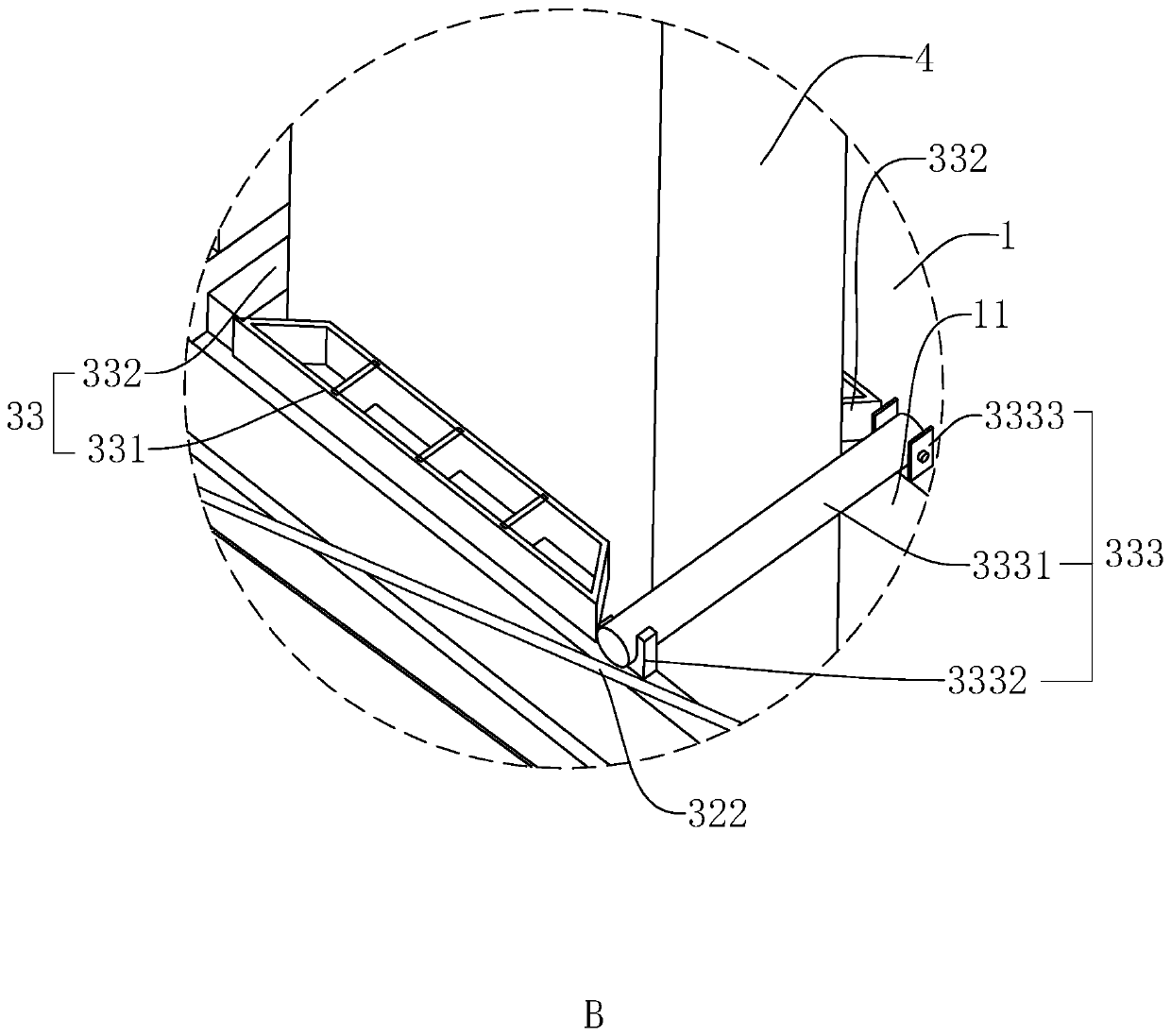

[0042] Such as figure 1 As shown, this embodiment introduces a piling equipment for underwater reinforced concrete prefabricated sheet piles, which is used to insert the sheet piles 4 into the river bottom after being hoisted on water. The piling equipment includes a hull 1, a pile driver 2 and a positioning device, the hull 1 floats above the water surface, the pile driver 2 and the positioning device are fixed above the hull 1, and the positioning device is used to fix the hull 1 relative to the river bottom to stabilize the position of the hull 1 , the piling machine 2 is used to hoist the sheet pile 4 and hammer the sheet pile 4 to the bottom of the river, so that the piling operation can be performed on the water surface, greatly reducing the construction difficulty and construction time of the underwater sheet pile construction.

[0043] Such as figure 1 As shown, the hull 1 is provided with a square relief groove 11, and one or both ends of the relief groove 11 are pre...

Embodiment 2

[0063] The present invention introduces a piling method for underwater reinforced concrete prefabricated piles, which adopts the piling equipment introduced in Embodiment 1, and specifically includes the following steps.

[0064] S1. Locate the position of the hull 1, and after the hull 1 is stopped, ensure that the inserted sheet pile 4 is located in the relief groove 11, and the middle part of the sheet pile 4 is provided with a pile hole 41. General positioning adopts GPRS positioning, and the result is more accurate, but other positioning methods are also applicable, and it is guaranteed that the sheet pile 4 inserted after the hull 1 has stopped is positioned in the relief groove 11 and gets final product.

[0065] S2. Fix the hull 1 relative to the river bottom. The fixed form here can be one or more of the mobile positioning mechanism 31, the tensioning structure 32 and the fixed positioning mechanism 34 introduced in the first embodiment, and can also be other forms, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com