Bearing apparatus and semiconductor processing equipment

A technology of carrying device and loading device, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as unsuitable multi-chip systems, adverse effects of process results, height deviation, etc., and achieve simple mechanical processing and electrical design Ease of operation, simplification of mechanical processing and electrical design, and improvement of position accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order for those skilled in the art to better understand the technical solutions of the present invention, the carrying device and semiconductor processing equipment provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

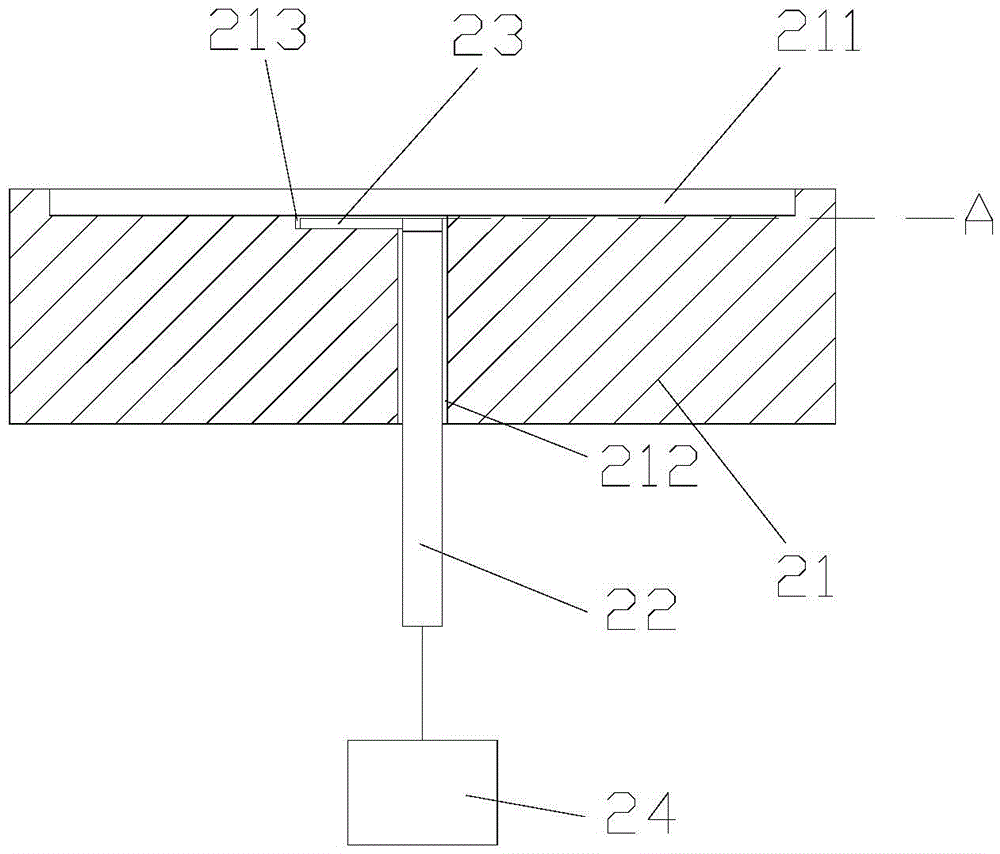

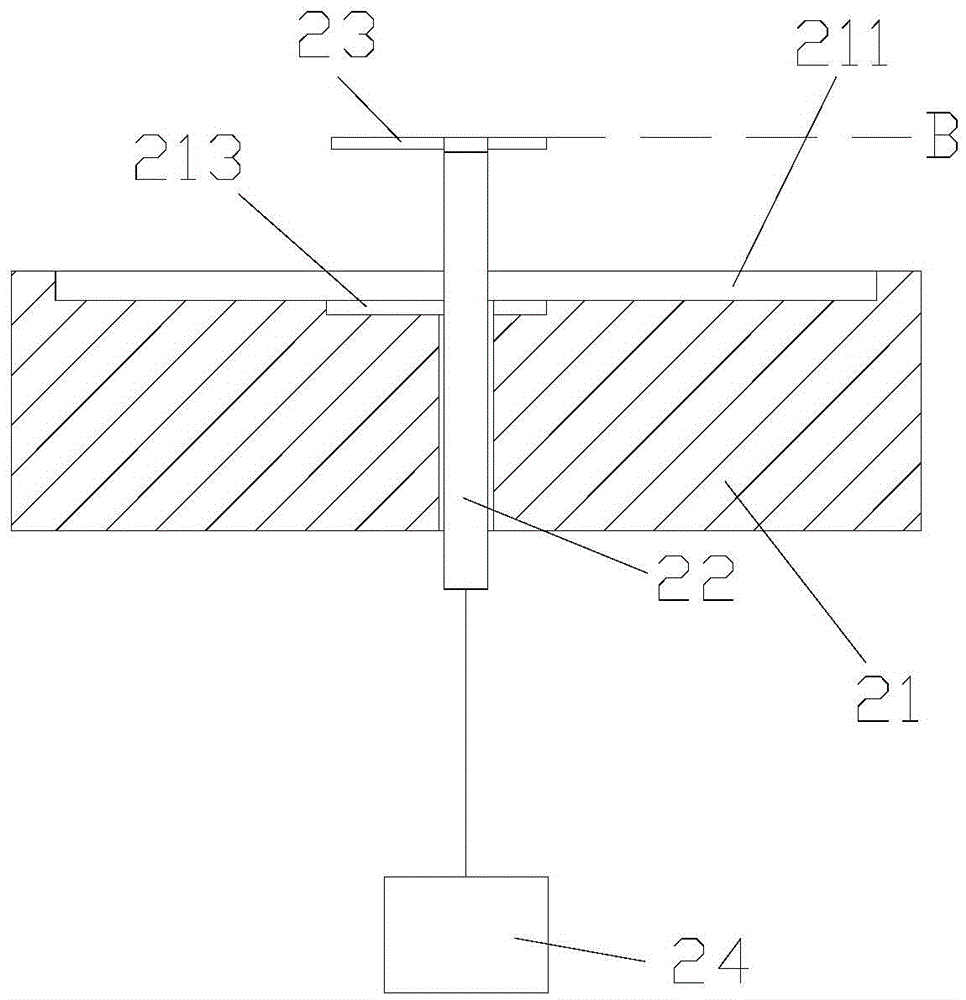

[0040] Figure 2A A cross-sectional view of the carrying device provided in a state according to the first embodiment of the present invention. Figure 2B A cross-sectional view of another state of the carrying device provided by the first embodiment of the present invention. Please also refer to Figure 2A and Figure 2B , the carrying device includes a base 21, a carrier and a lifting drive mechanism 24, wherein the base 21 includes a first carrying surface for carrying a wafer, and the first carrying surface refers to the part of the base 21 that is in contact with the lower surface of the wafer. surface. In this embodiment, there is one first bearing surface, which is concentric wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com