Intelligent folding production line for lining box

A production line, intelligent technology, applied in the direction of box making operations, paper/cardboard containers, container manufacturing machinery, etc., can solve the problem of side wall folding operation that cannot be used for barrel cavity structure, lack of process flexibility and scalability, and difficulty in adapting to boxes The problems of complex and changeable structure can be solved, and the effect of saving conveying space, optimizing folding space and folding path, and simple and reasonable structure can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

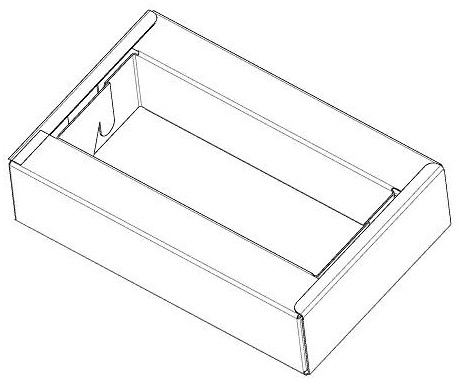

[0058] Such as figure 1 As shown in the paper lined box, the left and right sides of the lined box are the box walls of the rectangular tube cavity, and the two ends of the lined box are the box end walls of double-layer folded cardboard. The box walls of the rectangular bobbin chamber on both sides and the end walls of the double-layer box at both ends enclose the object holding chamber.

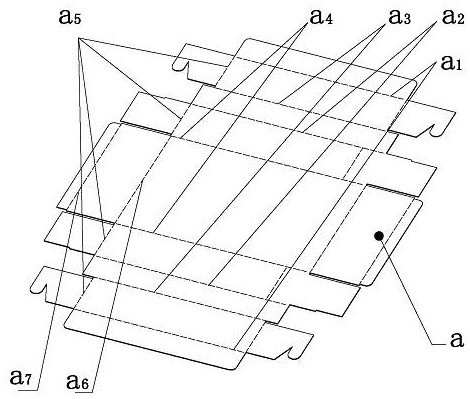

[0059] Such as figure 2 The unfolded folded cardboard a is shown, the surface of the folded cardboard a is provided with folded indentations a1, a2, a3, a4, a5, a6, a7 for folding, according to the folded indentations a1, a2, a3, The order of a4, a5, a6, a7 is gradually folded into a paper-lined box.

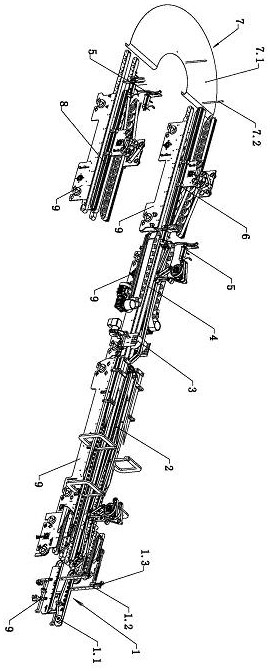

[0060] Such as image 3 The shown intelligent folding production line for liner boxes includes a frame 9, and the frame 9 adopts a segmented frame structure. A folding channel for folding cardboard a is formed penetratingly on the frame 9, and along the folding channel, a paper feeding d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com