A spherical polishing device for mechanical processing and its use method

A technology of mechanical processing and polishing devices, which is applied in the direction of grinding/polishing safety devices, surface polishing machine tools, cleaning methods using gas flow, etc., can solve the problems of friction between the polishing surface and the surface of the fixed seat, which is easy to cause scratches, etc. Achieve the effect of improving polishing effect, reducing contact area and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

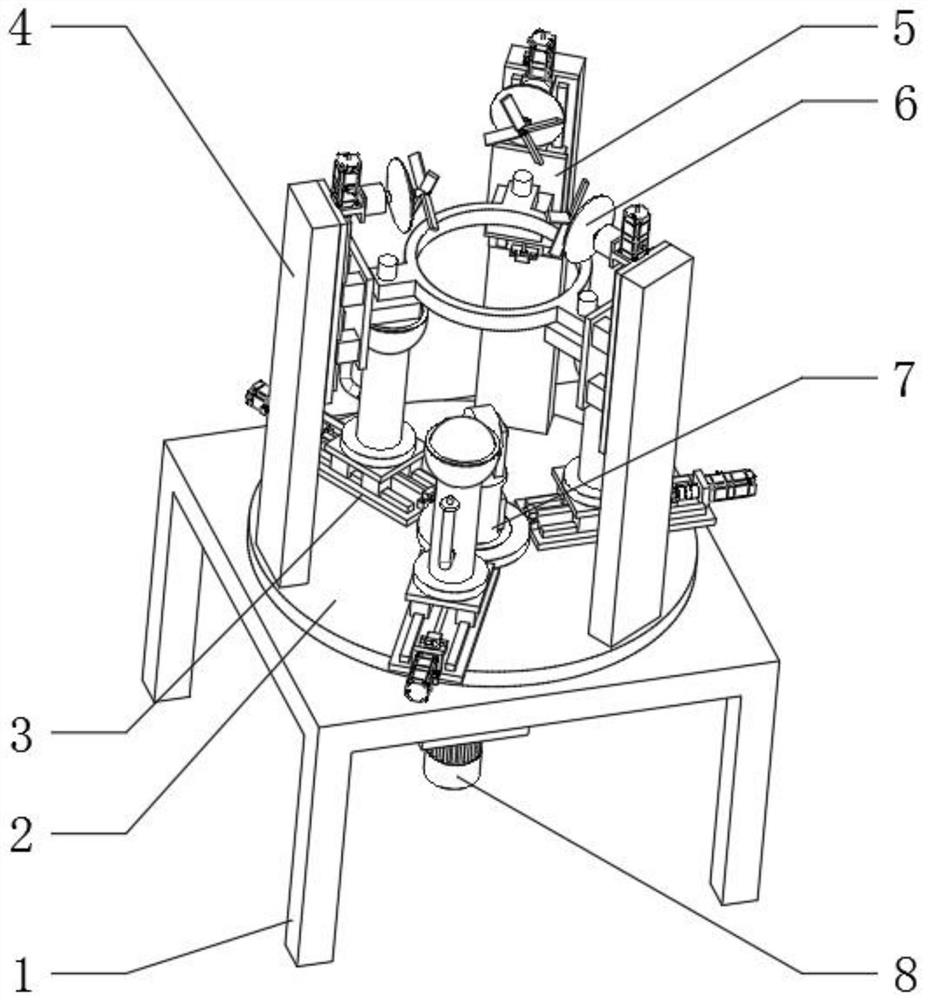

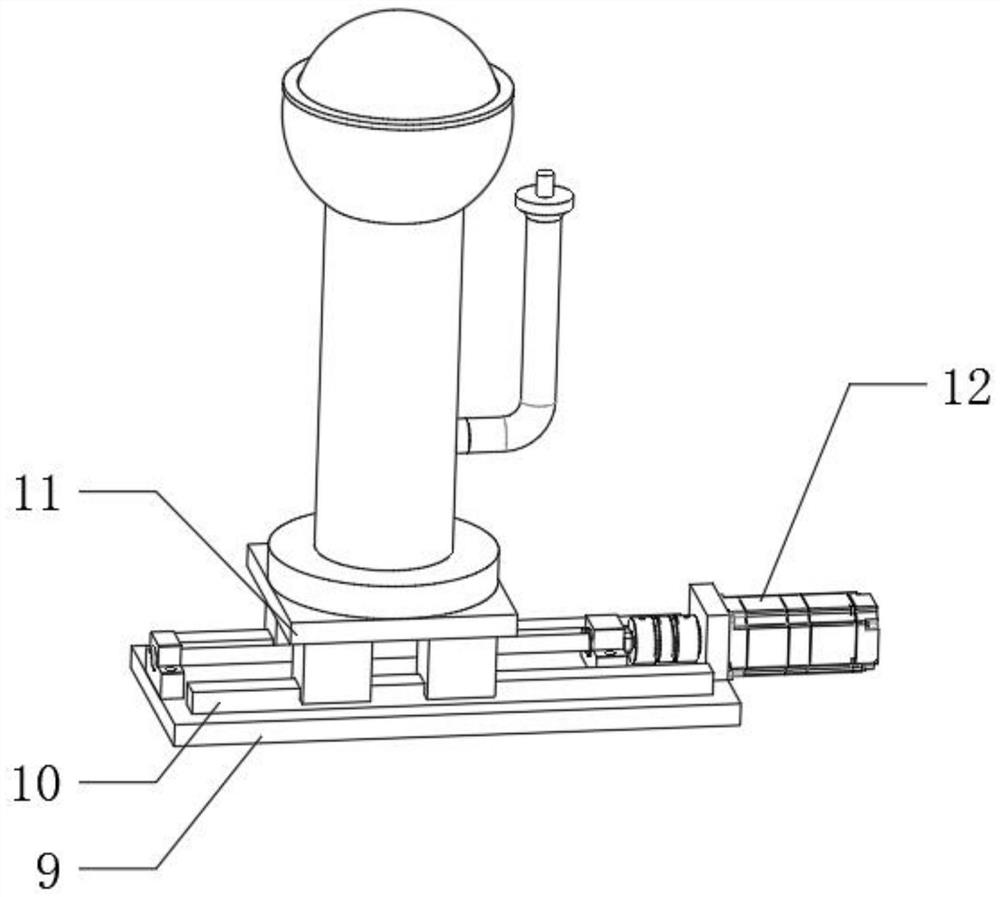

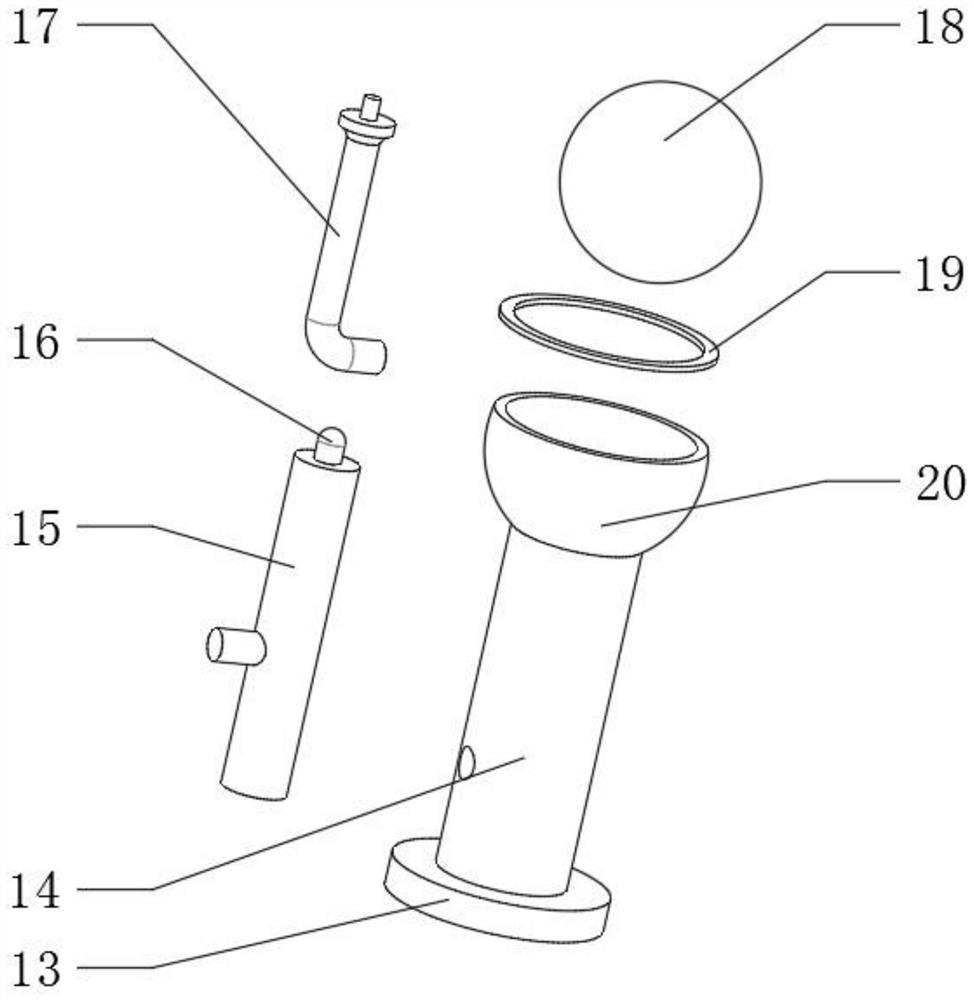

[0044] A spherical polishing device for mechanical processing, such as Figure 1-7 As shown, it includes a bottom plate 2, the top outer wall of the bottom plate 2 is fixedly connected with a support assembly 3 and a stand 4, the number of support assemblies 3 is three, and the outer wall of one side of the stand 4 is fixedly connected with a polishing assembly 5, and the polishing assembly 5 is one The side outer wall is fixedly connected with a chip blowing assembly 6, the bottom inner wall of the bottom plate 2 is fixedly connected with a power assembly 7, the bottom outer wall of the bottom plate 2 is fixedly connected with a frame 1, and the top inner wall of the frame 1 is fixedly connected with an adjustment assembly 8; the support assembly 3 includes Supporting plate one 9 and track one 10, the bottom outer wall of track one 10 is connected to the top outer wall of supporting plate one 9 by bolts, the bottom outer wall of supporting plate one 9 is fixedly connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com