Hydrostatic pressure guide rail system with actively controllable oil film thickness

A hydrostatic guide rail, oil film thickness technology, applied in large fixed members, metal processing machinery parts, metal processing equipment and other directions, can solve problems such as changes in guide rail stiffness and load capacity, reduce structural size, reduce difficulty, and excellent oil film. The effect of thickness dynamic control capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

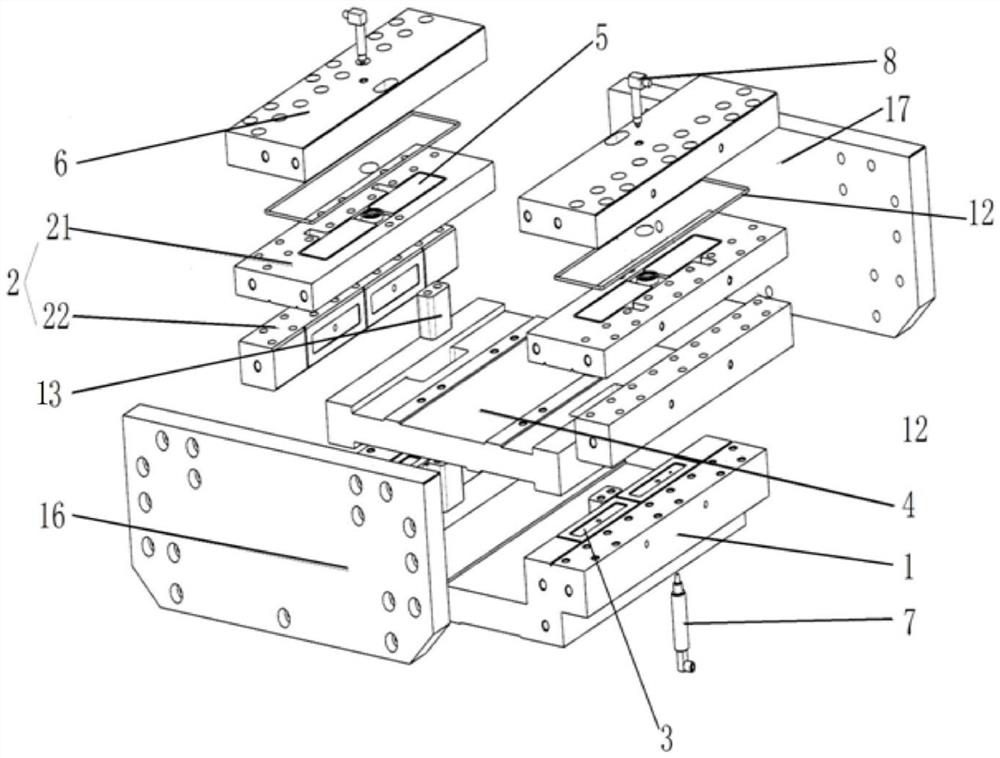

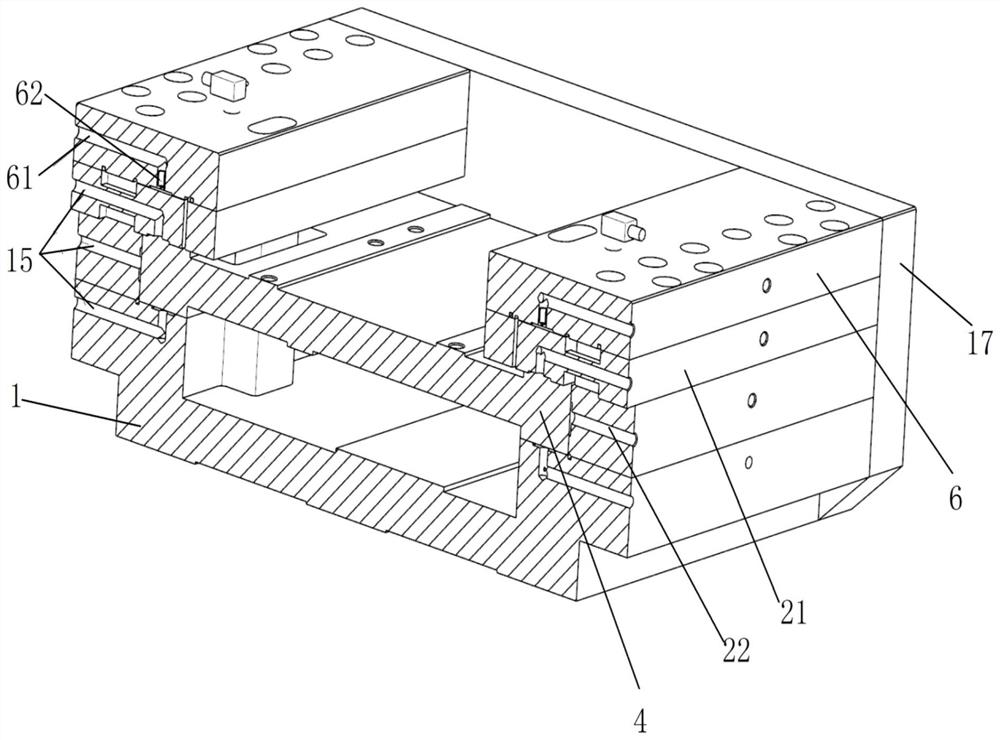

[0049] Such as figure 1 As shown in and , this embodiment provides a hydrostatic guide rail with actively controllable oil film thickness. The base 1 is provided with a sliding plate 4 , a thrust plate assembly 2 and a reinforcing block 13 . The base 1 and the thrust plate assembly 2 jointly form a left-right symmetrical first guide rail 90 and a second guide rail 91, which are distributed on both sides of the base 1, and each of the first guide rail 90 and the second guide rail 91 forms a semi-enclosed "C"-shaped structure. . A pressure cover plate 6 is provided directly above the upper thrust plate 21 .

[0050] The structure of slide plate 4 is as Figure 9 As shown, the gap between the first guide rail sliding surface of the slide plate 4 and the first guide rail 90 is 10 μm-40 μm.

[0051] The gap between the sliding surface of the second guide rail of the slide plate 4 and the second guide rail 91 is 10 μm-40 μm.

[0052] The base 1 and the thrust plate assembly are ...

Embodiment 2

[0062] Such as Figure 10 As shown, further optimization on the basis of Embodiment 1, the base 1 is provided with a reinforcement block 13 in the middle of the cantilever between the first guide rail 90 and the second guide rail 91 and the upper thrust plate 21 in the middle of the moving direction of the slide plate 4 .

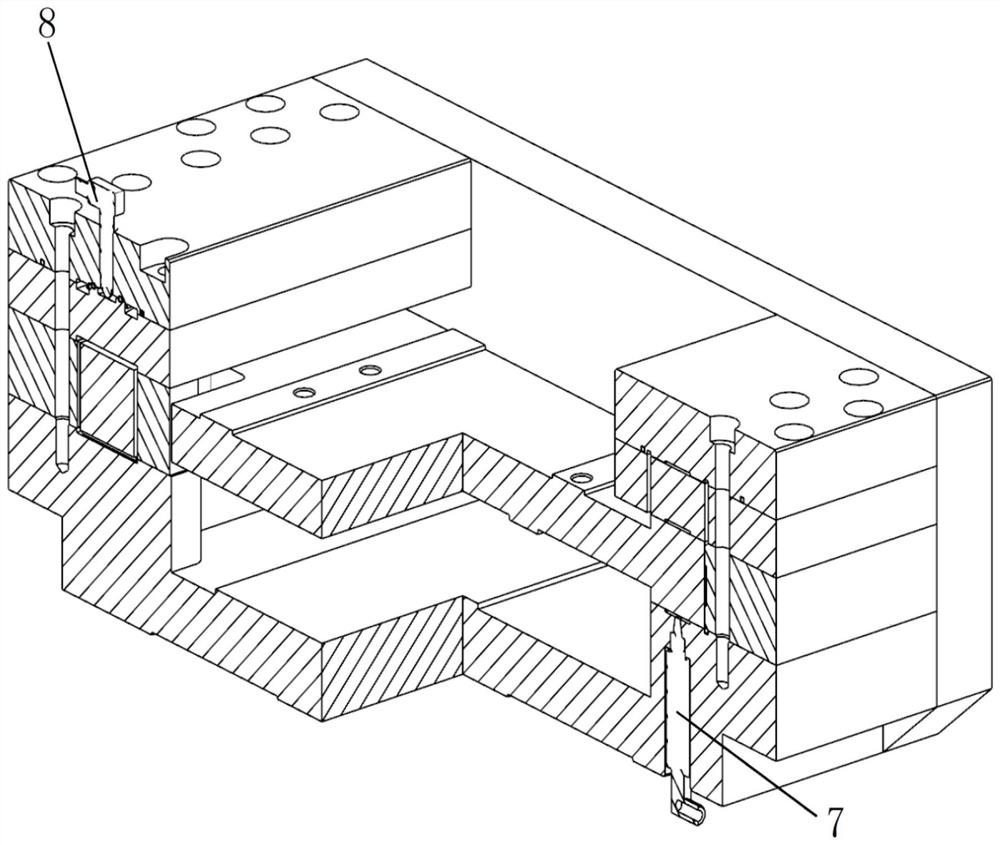

[0063] The base 1 is provided with a lower connecting plate 17 and an upper connecting plate 16 at the end of the moving direction of the slide plate 4 . The upper connecting plate 16 and the lower connecting plate 17 are respectively connected with the base 1, the thrust plate 21 and the pressure cover plate 6 using bolts. The sliding plate 4 is provided with through grooves on the left and right sides of the middle part of its moving direction, and the reinforcing blocks 13 pass through the grooves without contacting.

[0064] The base 1, the reinforcing block 13, the upper thrust plate 21 and the pressure cover plate 6 are connected by bolts. The joint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com