Negative electrode, preparation method thereof, and lithium ion battery using negative electrode

A negative electrode and deionized water technology, applied in electrode manufacturing, battery electrodes, secondary batteries, etc., can solve problems such as low viscosity, poor electrode performance, and poor electrode processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

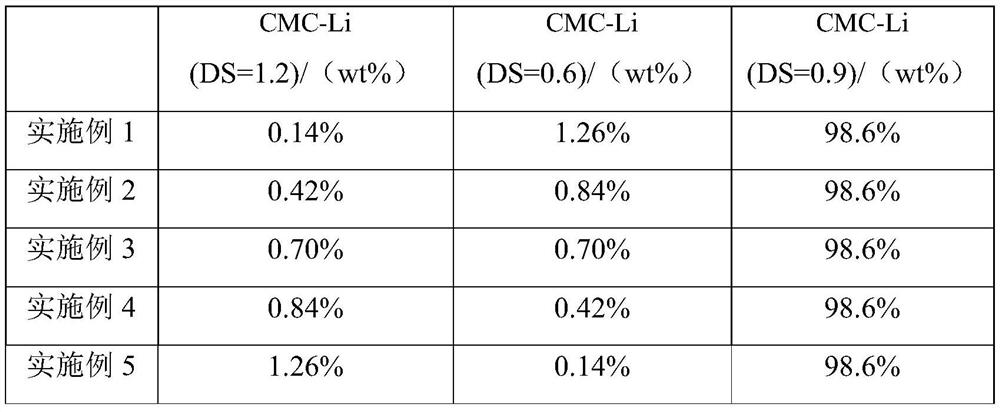

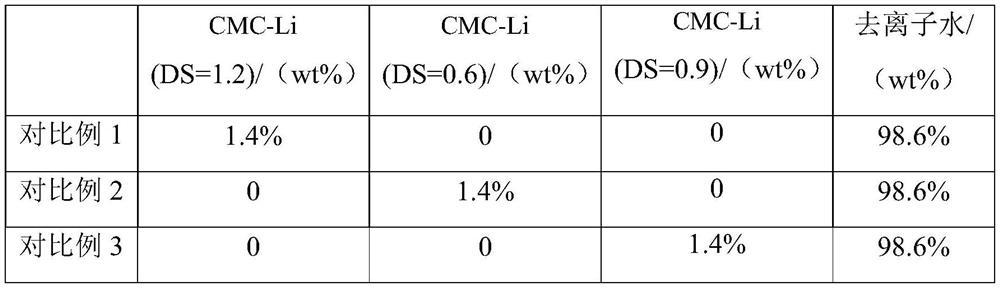

Examples

preparation example Construction

[0064] The method for preparing the negative electrode according to the first aspect of the present invention provided as the second aspect of the present invention comprises the steps of

[0065] a. Homogenizing: mixing and stirring the binder, the conductive agent, the negative electrode active material, and the electrode thickener to form a slurry;

[0066] b. Coating: the slurry is diluted with deionized water, coated on the current collector, and then compacted to form the negative electrode.

[0067] In one embodiment, the above coating is double-sided coating.

[0068] In one embodiment, the above-mentioned coating is carried out by a coating machine, and the coating speed ranges from 0.8 to 1.2 m / min -1 .

[0069] In one embodiment, the above-mentioned compaction is carried out by a roller press, and the compacted density ranges from 1.4 to 1.8 g / cm -3 , The rolling speed range is 0.6~1.0m / min.

[0070] In one embodiment, the above-mentioned binder is styrene-butad...

preparation example

[0077] [Preparation Example] Preparation of Electrode Thickener

[0078] Preparation of carboxymethylcellulose lithium (DS=1.2):

[0079] Method 1: Take cellulose raw materials (refined cotton, wood pulp, etc.) with an average degree of substitution of 1.2, add sodium hydroxide to alkalize, add monochloroacetic acid to react, and then add acetic acid solution, in a mixed solution of ethanol and water at 35°C After reacting for 2 hours, filter and wash repeatedly with the mixed solvent to obtain purified carboxymethyl cellulose, place the prepared carboxymethyl cellulose in a mixed solution of ethanol and water, and react with 7wt% LiOH at 50°C for 2 hours , adding acetic acid to adjust the pH value to x can obtain lithium carboxymethyl cellulose with an average substitution degree of 1.2.

[0080] Method 2: Take cellulose raw materials (refined cotton, wood pulp, etc.) with an average degree of substitution of 1.2, disperse them in a mixed solution of isopropanol and distille...

Embodiment 6

[0094] a. Homogenization: Disperse and mix 571 parts of electrode thickener and 8 parts of conductive agent prepared in Example 1 to form 579 parts of conductive glue, mix 579 parts of conductive glue with 966 parts of graphite and stir for 60 minutes (revolution 20rpm, rotation 800rpm) Form a slurry, then add 300 parts of deionized water to reduce the solid content to about 53%, continue to stir for 90min (revolution 35rpm, rotation 2500rpm, vacuum -90kPa), and finally add 45 parts of SBR emulsion and stir for 30min (revolution 20rpm, rotation 800rpm , vacuum degree-90kPa), complete the homogenization process.

[0095] b. Coating: The slurry is coated on the copper foil by a coating machine. The foil is coated on both sides. The coating surface density is controlled at about 10mg cm-2, and the coating speed is 1m / min-1. The temperature of the oven is maintained at around 65°C and 80°C.

[0096] c. Compaction: use a roller press, adjust the parameters of the roller press, so ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com