Metallized polypropylene film capacitor

A polypropylene film and capacitor technology, which is applied in the field of capacitors, can solve problems such as loose capacitor parts, vibration of power equipment, and damaged capacitors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

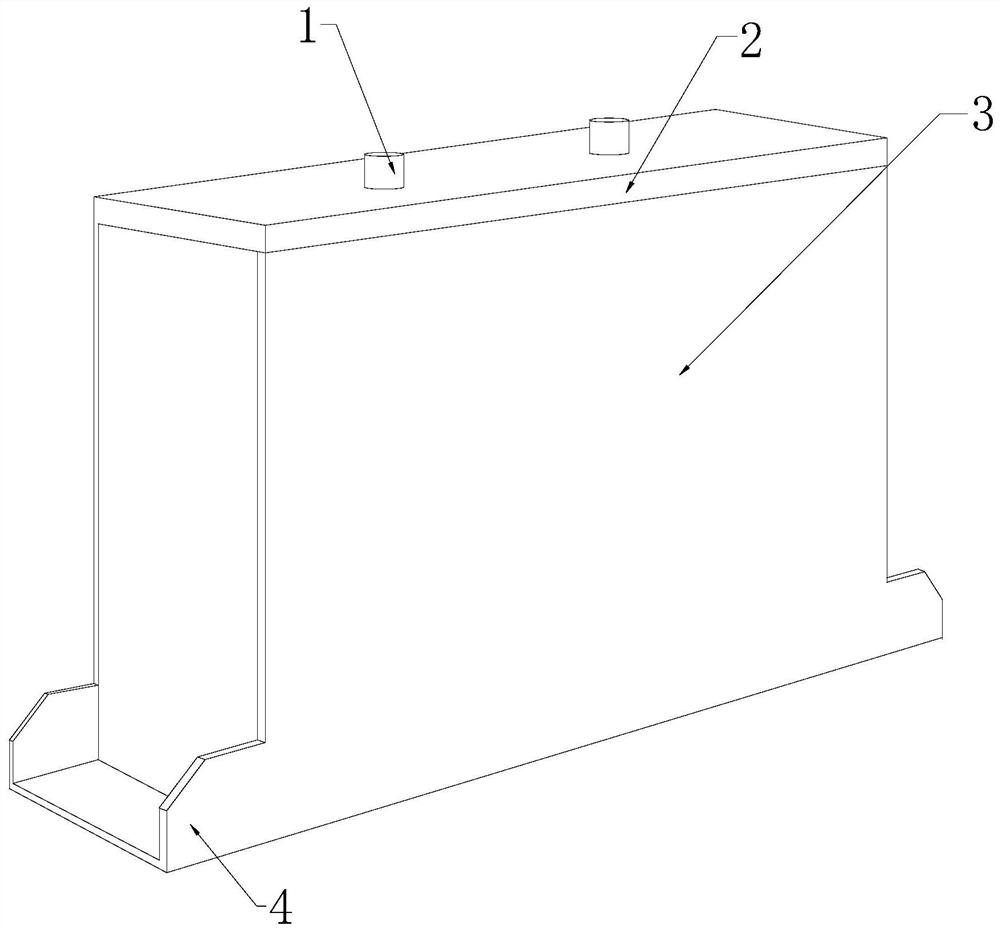

[0029] see Figure 1-Figure 5 , a metallized polypropylene film capacitor, its structure includes a terminal 1, a closing cover 2, an equipment box 3, and a mounting bracket 4, the terminal 1 is installed on the closing cover 2, and the closing cover 2 is installed on the equipment box 3, the mounting bracket 4 and the equipment box 3 are an integrated structure;

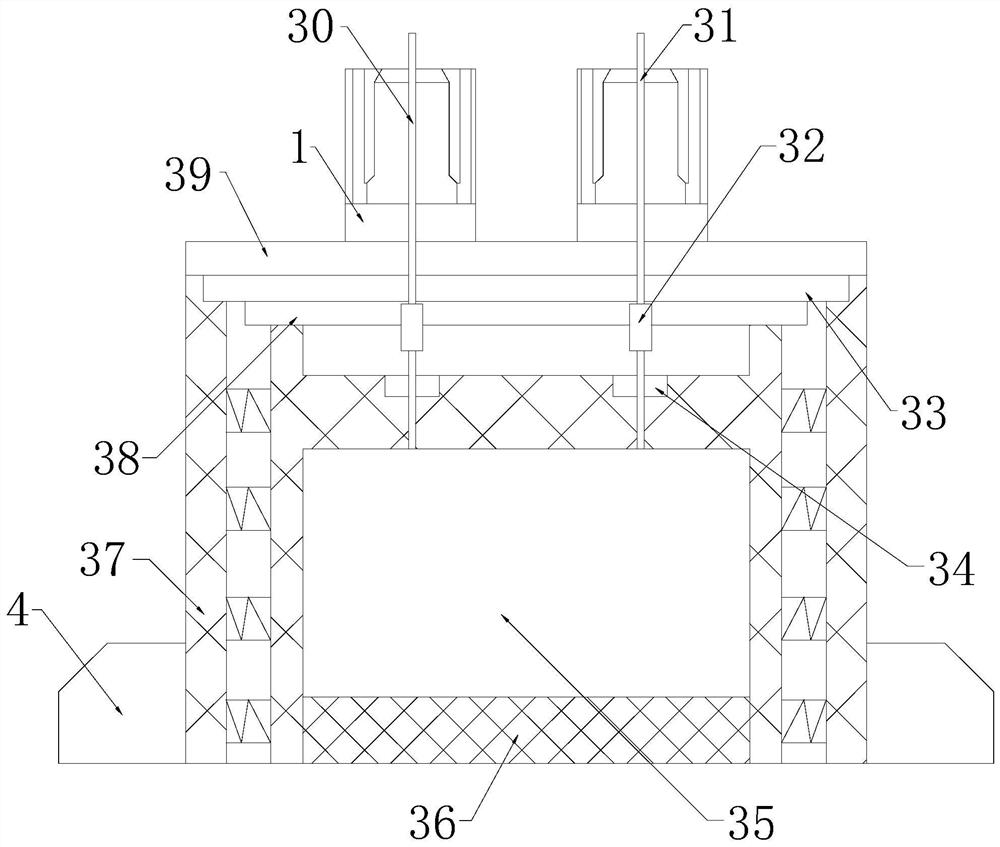

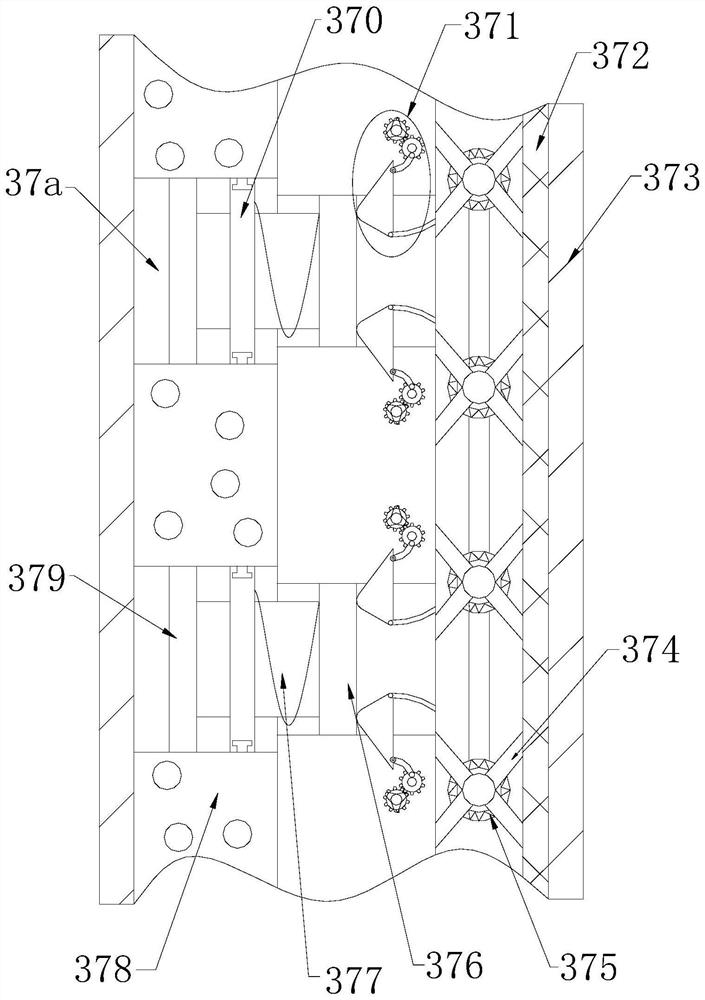

[0030] The equipment box 3 is provided with a positive pole 30, a negative pole 31, a fuse 32, an explosion-proof cover 33, a connection hole 34, a capacitor core 35, a bottom shock absorber 36, a side anti-vibration body 37, a heat dissipation cover 38, and an end cover 39. The positive pole 30 is installed on the end cover 39, the side of the end cover 39 is provided with the negative pole 31, the explosion-proof cover 33 is provided under the end cover 39, and the heat dissipation cover 38 is installed on the explosion-proof Below the cover plate 33, the fuse 32 is fixedly installed with the positive electrode r...

Embodiment 2

[0037] see Figure 1-Figure 7 , a metallized polypropylene film capacitor, its structure includes a terminal 1, a closing cover 2, an equipment box 3, and a mounting bracket 4, the terminal 1 is installed on the closing cover 2, and the closing cover 2 is installed on the equipment box 3, the mounting bracket 4 and the equipment box 3 are an integrated structure;

[0038] The equipment box 3 is provided with a positive pole 30, a negative pole 31, a fuse 32, an explosion-proof cover 33, a connection hole 34, a capacitor core 35, a bottom shock absorber 36, a side anti-vibration body 37, a heat dissipation cover 38, and an end cover 39. The positive pole 30 is installed on the end cover 39, the side of the end cover 39 is provided with the negative pole 31, the explosion-proof cover 33 is provided under the end cover 39, and the heat dissipation cover 38 is installed on the explosion-proof Below the cover plate 33, the fuse 32 is fixedly installed with the positive electrode r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com