Renewable resource foaming material and preparation method thereof

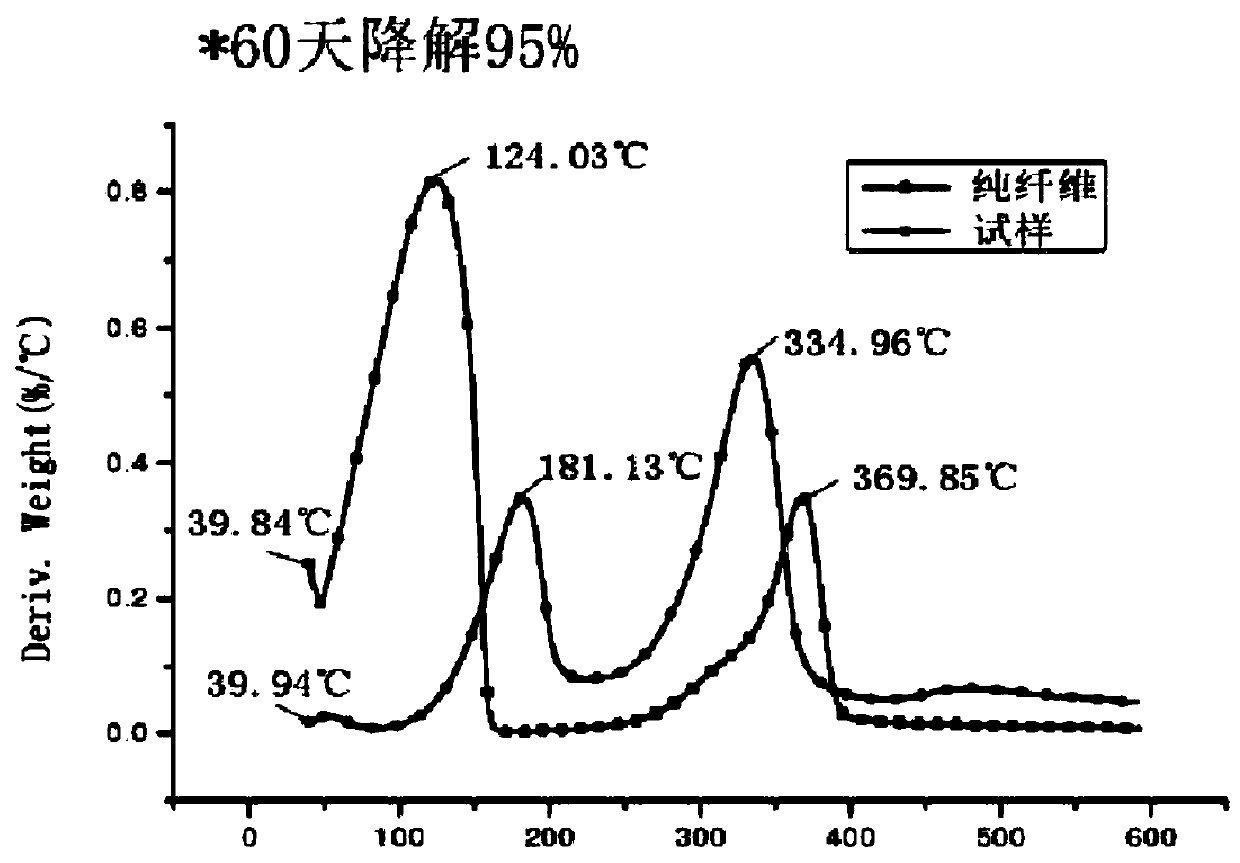

A technology for renewable resources and foaming materials, applied in the field of packaging materials, can solve the problems of difficult to experiment with high yield, low production efficiency, long foaming time, etc., and achieve the effects of excellent physical performance indicators, cost savings, and internal uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A renewable resource foaming material, comprising the following components, in parts by weight: 75 parts of recycled resource fiber, 30 parts of water-soluble polyurethane, 7 parts of starch binder, 3 parts of foaming agent, 2 parts of PVA film-forming agent , 2 parts of light calcium carbonate nucleating agent, 1 part of borax nucleating agent.

[0035] The recycled resource fiber is a mixture of rice straw rubbing fiber, dehydrated and dried cow dung, and recycled and crushed waste corrugated paper in a ratio of 5:3:2.

[0036] The foaming agent is a mixture of ammonium bicarbonate and azodicarbonamide in a ratio of 3:1.

[0037] The preparation method of the renewable resource foaming material in this embodiment comprises the following steps:

[0038] (1) After the recycled resource fiber and water are fully mixed according to the ratio of 2:3, then the synthetic fiber, dispersion liquid, foaming agent, adhesive, film-forming agent and nucleating agent are added in ...

Embodiment 2

[0042] A renewable resource foaming material, comprising the following components in parts by weight: 60 parts of wheat straw-rolled fiber, 60 parts of water-soluble polyurethane, 10 parts of starch adhesive, 5 parts of PVA film-forming agent, foaming agent 3 parts, 2 parts of borax nucleating agent.

[0043] The foaming agent is a mixture of ammonium bicarbonate and organic foaming agent sodium lauryl sulfate in a ratio of 20:1.

[0044] The preparation method of the renewable resource foaming material in this embodiment comprises the following steps:

[0045] (1) After the straw plant fiber silk and water are fully mixed according to the ratio of 2:3, then the synthetic fiber, dispersion liquid, foaming agent, adhesive, film forming agent and nucleating agent are added in parts by weight and fully mixed to form a slurry ;

[0046](2) The slurry is injected into the forming mold, and the excess moisture is sucked and filtered out by vacuum negative pressure, so that the moi...

Embodiment 3

[0049] A renewable resource foaming material, comprising the following components in parts by weight: 50 parts of straw plant fiber, 20 parts of polypropylene fiber, 45 parts of water-soluble polyurethane, 10 parts of foaming agent, and 5 parts of starch binder , 4 parts of PVA film-forming agent, 1 part of borax.

[0050] The foaming agent is a mixture of isocyanate end groups and water in a ratio of 100:20.

[0051] The preparation method of the renewable resource foaming material in this embodiment comprises the following steps:

[0052] (1) fully mixing the dry straw plant fiber silk with the synthetic fiber, dispersion liquid, foaming agent, adhesive, film-forming agent and nucleating agent in parts by weight to form a slurry;

[0053] (2) Inject the slurry into the random crack diversity cavity, and after standing at room temperature for 30 seconds, it starts to solidify and form gradually to obtain a plant fiber foam filling material, which has the characteristics of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com