Preparation method of carbon nitride electrode material

An electrode material, carbon nitride technology, applied in chemical instruments and methods, nitrogen compounds, cable/conductor manufacturing, etc., can solve the problems of complex and harsh synthesis conditions, uneven CN film, poor substrate contact, etc., and achieve simple preparation technology. The effect of easy operation, uniform thin film, and excellent photoelectrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

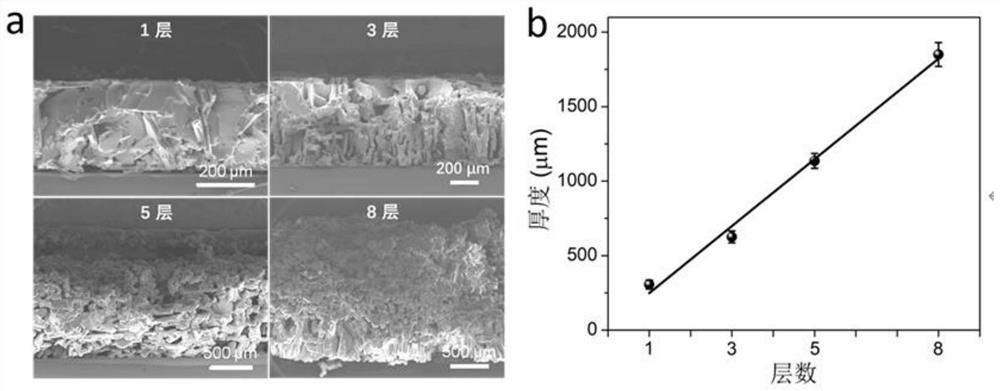

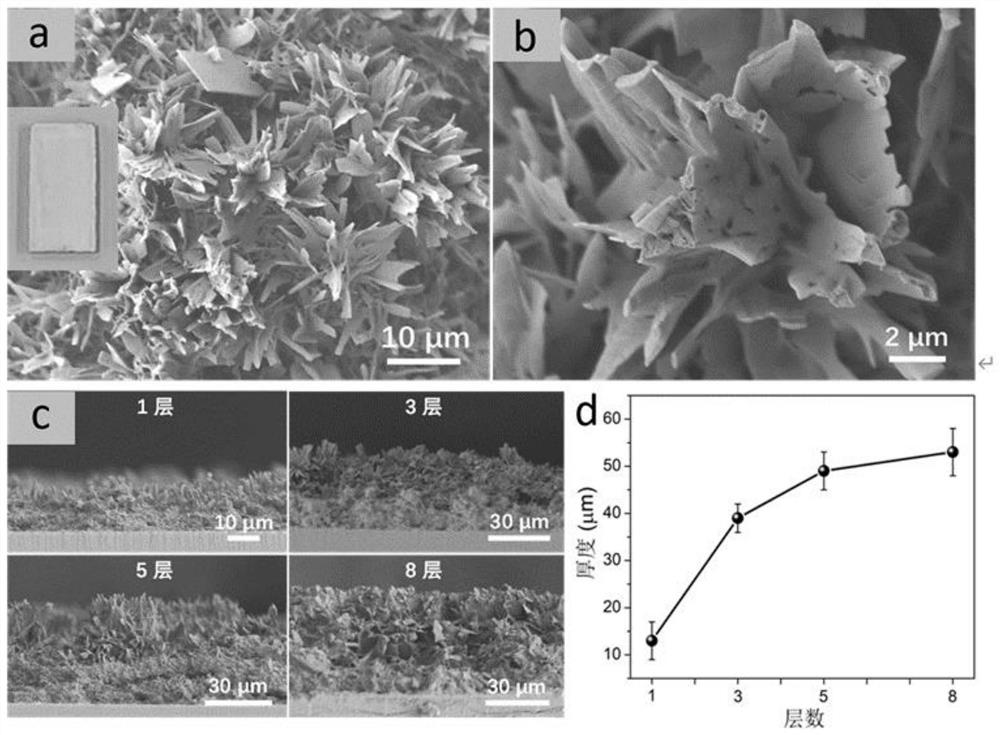

[0032] Add thiourea powder into a glass bottle containing 20ml of deionized water, and heat it to 70°C while stirring. After reaching saturation, then quickly immerse the clean FTO glass piece vertically into the hot saturated solution and take it out immediately. After the surface is dry , a uniform thiourea film layer was formed on the FTO. The thickness of the thiourea film can be adjusted by repeating the above steps for multiple dip-dry cycles. Thiourea films with thickness of 1, 3, 5 and 8 layers were prepared respectively. The thiourea film was dried in an oven at 60°C or air-dried naturally. Put the above dried thiourea film into a glass tube, pass nitrogen gas to drive away the air in the tube, wrap the tube mouth with tin foil, then put the glass tube in a nitrogen furnace for calcination at a high temperature of 500°C for 2 hours, and the heating rate is 5°C / min, after natural cooling, a uniform CN film electrode can be obtained. CN film electrodes with differen...

Embodiment 2

[0037] Add thiourea powder into a glass bottle containing 20ml of deionized water, heat it to 60°C while stirring, and then dip the clean FTO glass piece vertically into the hot saturated solution quickly and take it out immediately. After the surface is dry, A uniform thiourea film layer was formed on the FTO. The thiourea film was dried in an oven at 60°C or air-dried naturally. Put the above dried thiourea film into a glass tube, pass through nitrogen to drive away the air in the tube, wrap the tube mouth with tinfoil, and then put the glass tube in a nitrogen furnace for high temperature calcining at 450°C for 4 hours, with a heating rate of 2°C / min, after natural cooling, a uniform CN film electrode can be obtained. ( Figure 7 )

Embodiment 3

[0039] Add thiourea powder into a glass bottle containing 20ml of deionized water, heat it to 120°C while stirring, then quickly immerse the clean FTO glass piece vertically into the hot saturated solution and take it out immediately. After the surface is dry, put it on the FTO A uniform thiourea film layer was formed. The thiourea film was dried in an oven at 60°C or air-dried naturally. Put the above dried thiourea film into a glass tube, pass through nitrogen to drive away the air in the tube, wrap the tube mouth with tinfoil, then put the glass tube in a nitrogen furnace for calcination at a high temperature of 550°C for 3 hours, and the heating rate is 40°C / min, after natural cooling, a uniform CN thin film electrode can be obtained. ( Figure 7 )

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com