Deep gas-containing coal rock pulse fracturing experiment device and experiment method

An experimental method, gas-coal technology, applied in the direction of measuring devices, using repeated force/pulsation force to test the strength of materials, instruments, etc., can solve the problems of insufficient power, unsatisfactory effect of pressure relief and anti-reflection, etc., and achieve practical and realistic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

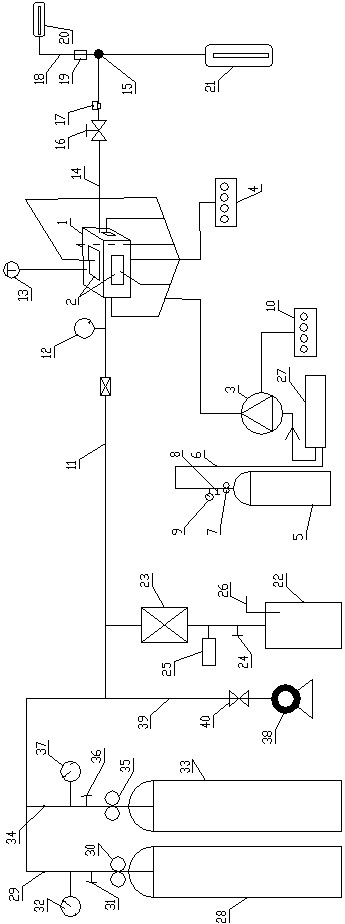

[0041] Such as figure 1 As shown, the deep gas-containing coal rock pulsation fracturing experiment system of the present invention includes a triaxial holder 1 for clamping and loading of coal samples. The triaxial holder 1 has an air inlet port and is used for discharging after the experiment ends. Gas outlet port;

[0042] The triaxial holder 1 is connected with six sets of loading devices 2 for applying pressure (ie stress) to the coal sample; the six sets of loading devices 2 are respectively located in front, rear, left, right, above and below the coal sample, six The sleeve loading device 2 is connected with a pulsating pump 3 for providing loading pressure and a first electric control device 4 for controlling the loading device 2;

[0043] The air inlet of the pulsation pump 3 is connected with a carbon dioxide cylinder 5, and the outlet pipeline 6 of the carbon dioxide cylinder 5 is provided with a third decompression valve 7, a third valve 8 and a third pressure gau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com