Gap automatic compensating type underwater rotation servo valve

An underwater rotation and automatic compensation technology, applied in the field of servo valves, can solve problems such as stuck, valve core stuck, poor anti-pollution ability, etc., to achieve automatic compensation, reduce leakage, and reduce leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention. In addition, the technical features involved in the various embodiments of the present invention described below can be combined with each other as long as they do not constitute a conflict with each other.

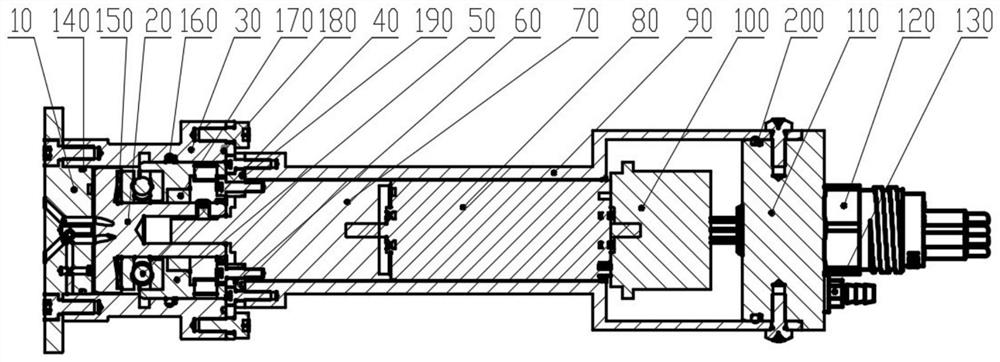

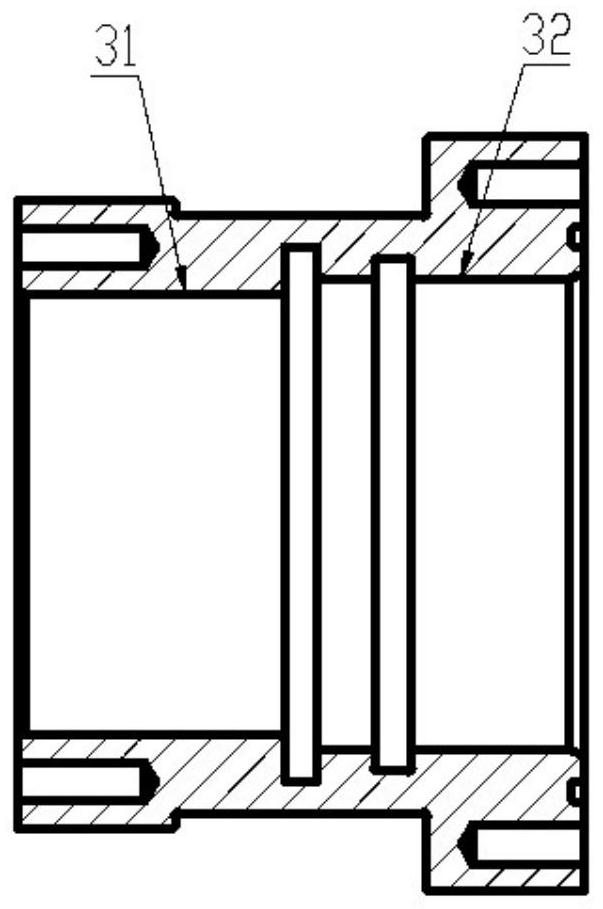

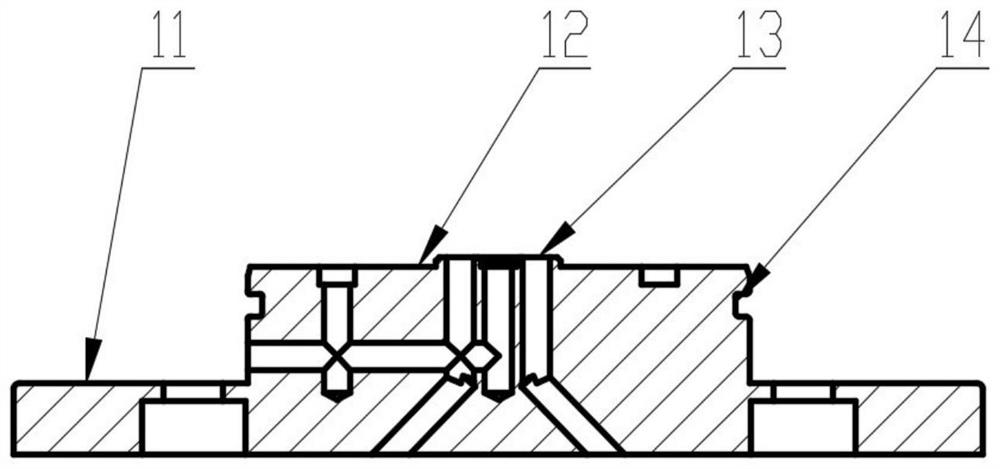

[0031] Such as figure 1 As shown, the present invention provides an automatic gap compensation type underwater rotary servo valve, which includes a lower end cover 10, a valve core 20, a valve body 30, a thrust ball bearing 40, a gland 50, and an upper end cover 60 , reducer 70, motor 80, motor package shell 90, rotary transformer 100, motor package end cover 110, watertight connector 120 and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com