Titanium wire processing method and equipment

A processing equipment, titanium wire technology, applied in lighting and heating equipment, heating to dry solid materials, drying, etc., can solve the problems of not conforming to the concept of environmental protection and low carbon, difficult replacement, complex structure, etc., to achieve the purpose of increasing the residence time Time, simplified structure, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

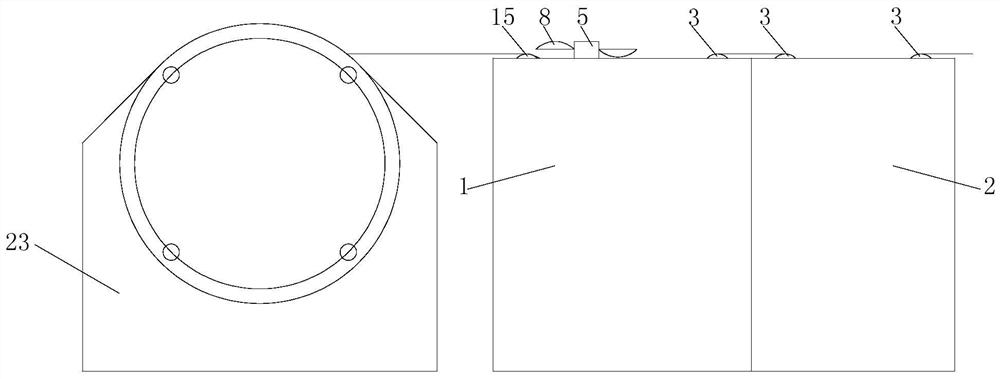

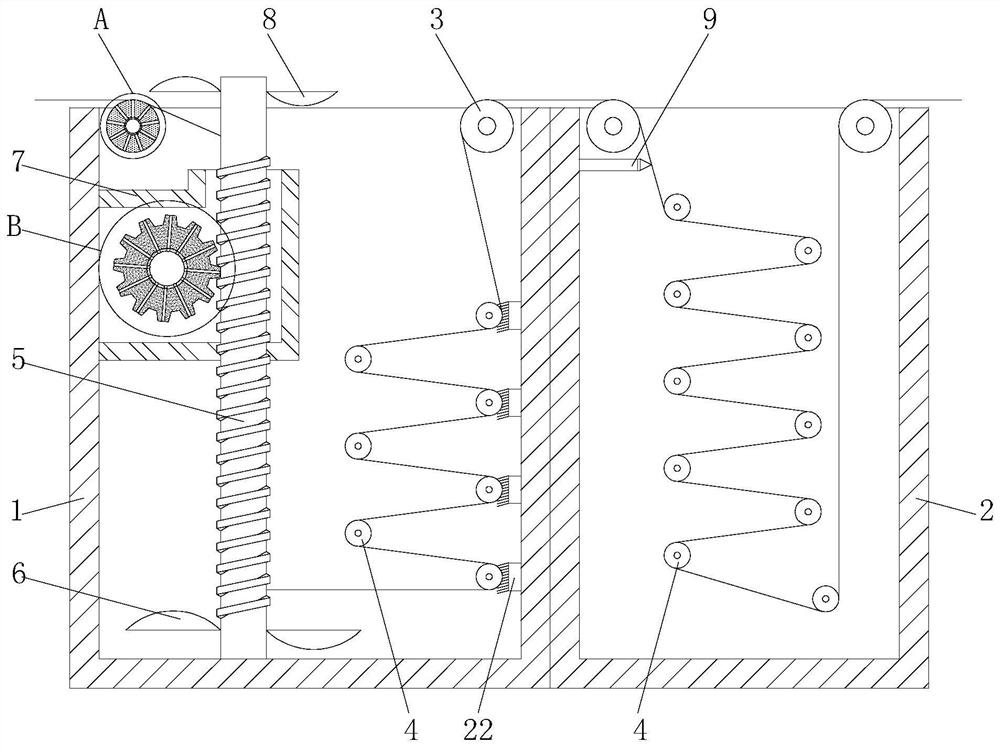

[0036] Such as Figure 1-6 As shown, the present invention provides a kind of technical scheme:

[0037]A processing equipment for titanium wire, including a rinsing chamber 1, a pickling chamber 2 and a material receiving machine 23. The rinsing chamber 1 is filled with deionized rinsing liquid, and the pickling chamber 2 is filled with acid liquid, which is 38w.t. % hydrochloric acid solution, 30w.t.% hydrobromic acid solution and 92w.t.% sulfuric acid solution are mixed and prepared according to the volume ratio of 1:1:2. The finished titanium wire is wrapped with lubricating oil and some other Impurities, after being cleaned by the pickling chamber 2 and the rinsing chamber 1, the lubricating oil and other impurities adhering to the titanium wire, including oxides wrapped on the titanium wire, can be washed away, so that the quality of the titanium wire can be improved. An air flow chamber 10 is fixedly installed outside the chamber 1, and the air flow chamber 10 provides...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| reduction of area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com