Automatic blanking, feeding and positioning device for automatic machining of pliers

A positioning device and automatic technology, applied in the direction of grinding drive devices, metal processing equipment, manufacturing tools, etc., can solve problems such as high cost, achieve low cost, avoid investment, and realize the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

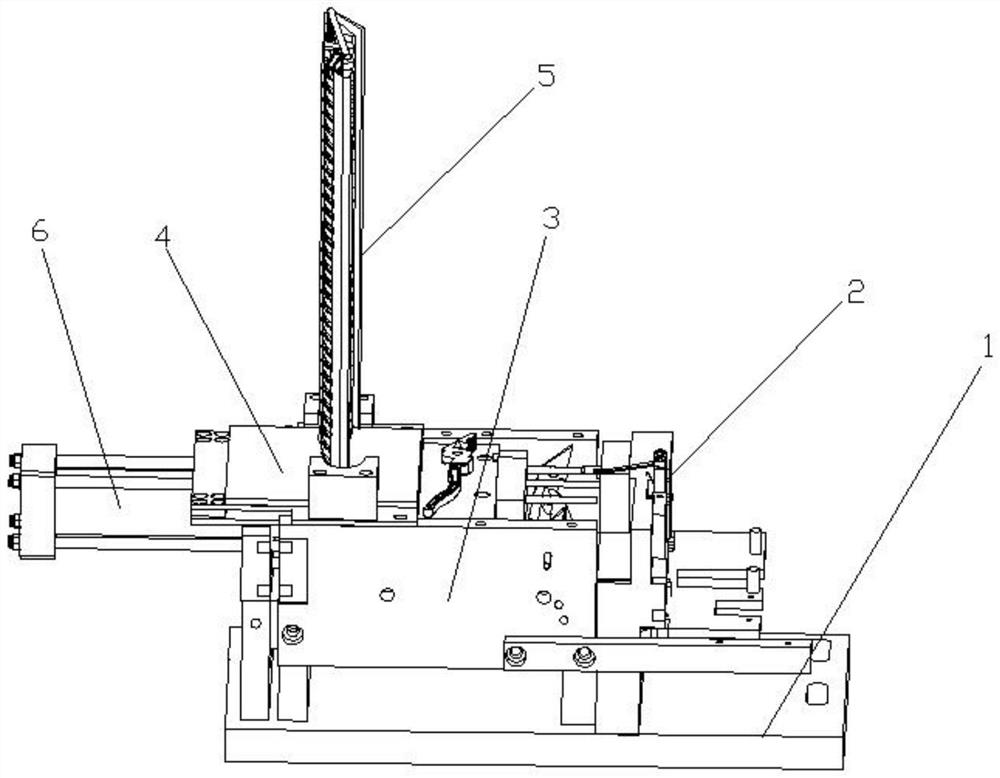

[0035] like figure 1 As shown, an automatic blanking, feeding, and positioning device for automatic processing of pliers includes: a base plate 1, a frame 3 is fixedly arranged on the upper surface of the base plate 1, and a feeding device for transporting the pliers body 10 is arranged on the frame 3 4. The positioning device 2 for positioning the pliers 10, and the blanking device 5 for placing the pliers 10 on the feeding device 4, the blanking device 5 includes a fixed frame 501 for fixing the pliers 10, the fixed frame The lower end of 501 is provided with a stopper 503 for preventing the pliers body 10 from falling, and the fixed frame 501 is provided with a switch device 502 for controlling the opening and closing of the stopper 503 .

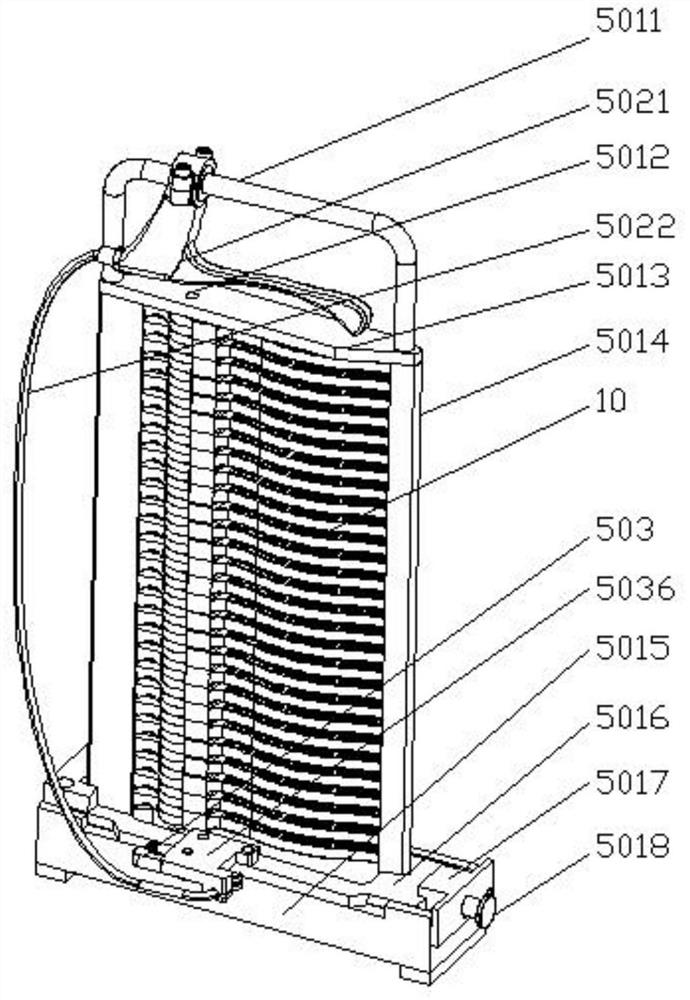

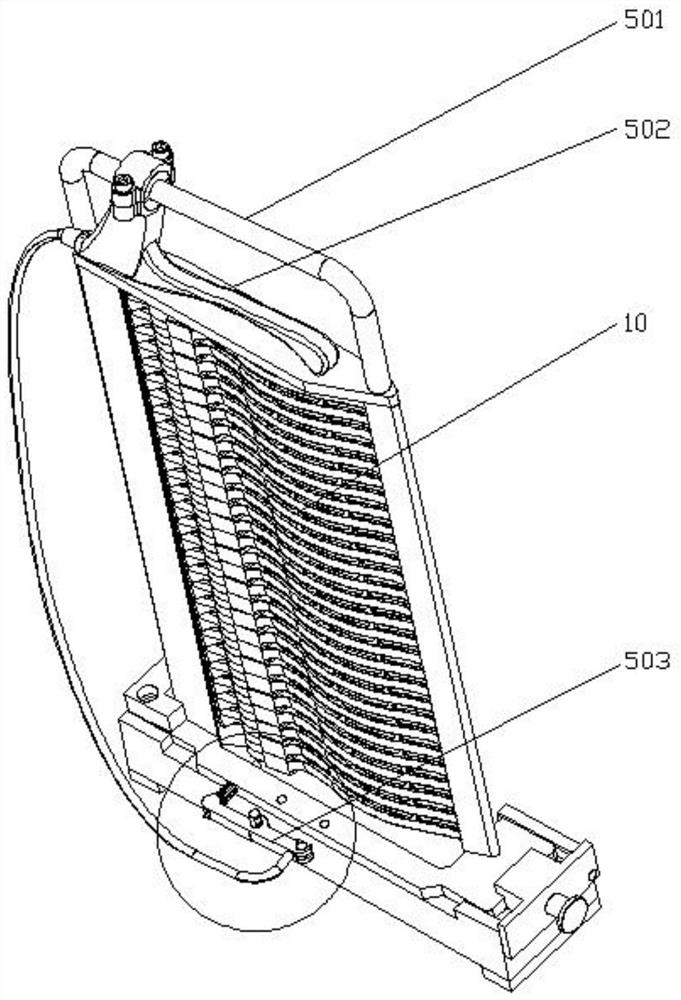

[0036] like Figure 2-Figure 3 As shown, in this embodiment, the fixed frame 501 includes an upper mounting plate 5013, a limit bar 5014 for limiting the movement of the pliers 10 in the horizontal direction, and a mounting base, and t...

Embodiment 2

[0045] like figure 1 As shown, an automatic blanking, feeding, and positioning device for automatic processing of pliers includes: a base plate 1, a frame 3 is fixedly arranged on the upper surface of the base plate 1, and a feeding device 4 for transporting the pliers body is arranged on the frame 3 , the positioning device 2 for positioning the pliers, and the blanking device 5 for placing the pliers on the feeding device 4, the blanking device 5 includes a fixed frame 501 for fixing the pliers, and the lower end of the fixed frame 501 is arranged There is a stopper device 503 for preventing the pliers from falling, and a switch device 502 for controlling the opening and closing of the stopper device 503 is arranged on the fixed frame 501 .

[0046] like Figure 2-Figure 3 As shown, in this embodiment, the fixed frame 501 includes an upper mounting plate 5013, a limit bar 5014 for limiting the movement of the pliers in the horizontal direction, and a mounting base. The mid...

Embodiment 3

[0059] like figure 1 As shown, an automatic blanking, feeding, and positioning device for automatic processing of pliers includes: a base plate 1, a frame 3 is fixedly arranged on the upper surface of the base plate 1, and a feeding device 4 for transporting the pliers body is arranged on the frame 3 , the positioning device 2 for positioning the pliers, and the blanking device 5 for placing the pliers on the feeding device 4, the blanking device 5 includes a fixed frame 501 for fixing the pliers, and the lower end of the fixed frame 501 is arranged There is a stopper device 503 for preventing the pliers from falling, and a switch device 502 for controlling the opening and closing of the stopper device 503 is arranged on the fixed frame 501 .

[0060] like Figure 2-Figure 3 As shown, in this embodiment, the fixed frame 501 includes an upper mounting plate 5013, a limit bar 5014 for limiting the movement of the pliers in the horizontal direction, and a mounting base. The mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com