Processing method for push rod connecting base

A processing method and connecting seat technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of slow drilling, ineffective control, affecting production progress, etc., to achieve accurate drilling positioning and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

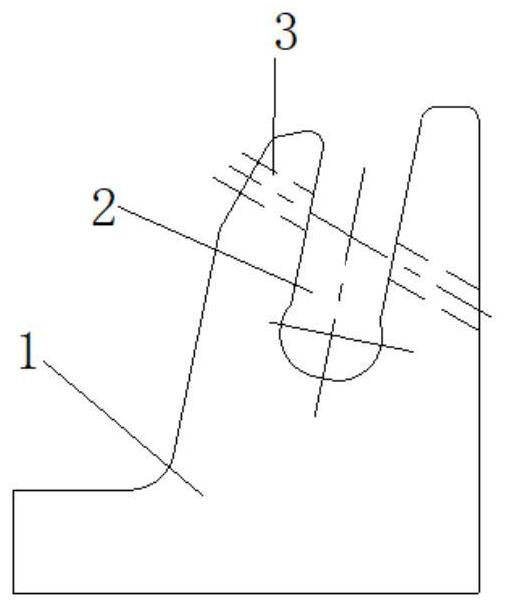

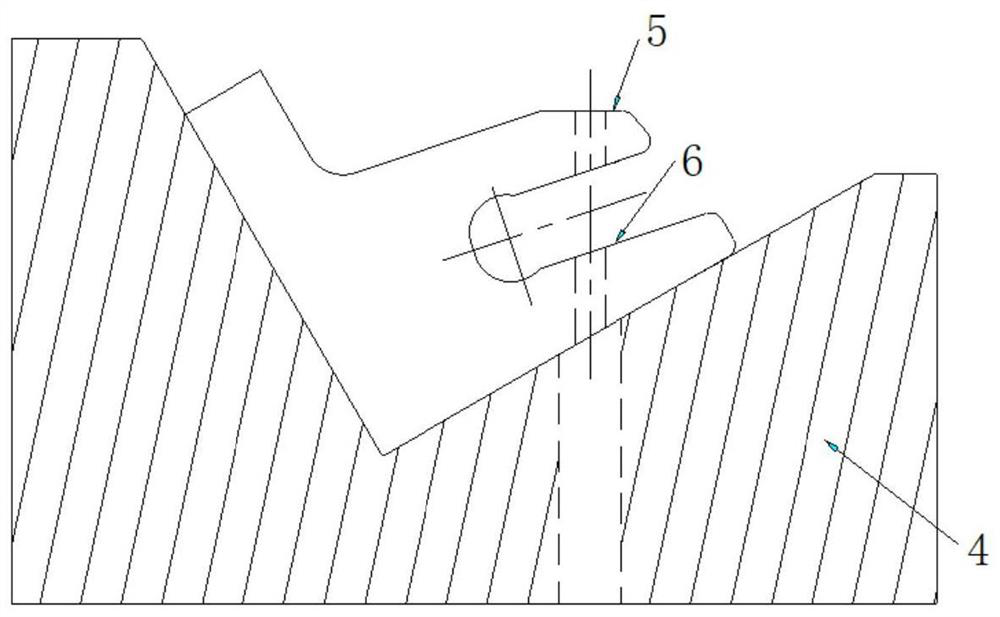

[0022] Such as Figure 1a , Figure 1b As shown, the connecting seat of the push rod is generally formed by blanking steel plates made of Q550 and Q690, and the U-shaped groove is mostly in the form of an inclined groove. At the same time, the pin hole is also in the form of an inclined hole. Hole, place the connecting seat on the tooling of the inclined hole to ensure the vertical direction of the hole, which is convenient for drilling. However, the U-shaped groove is in the form of a beveled edge, and the material hardness is relatively high. The front end of the drill bit has no guide, which may easily cause the drill bit to deviate when entering the hole, resulting in problems such as misalignment of the hole and deviation.

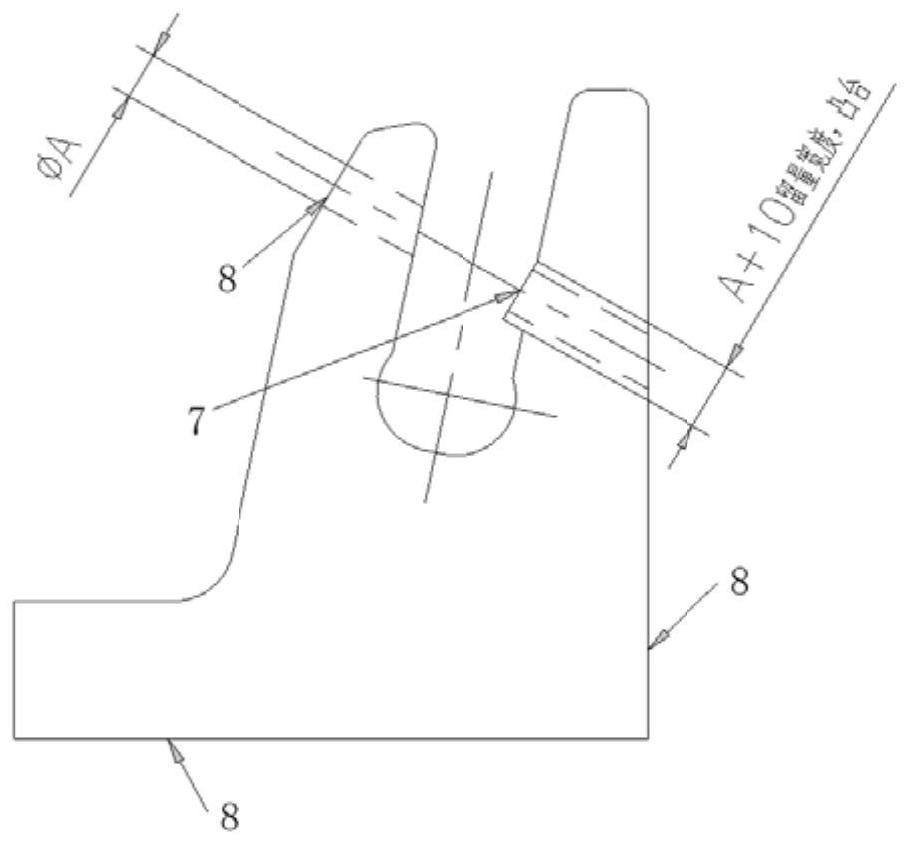

[0023] Such as Figure 2a , Figure 2b As shown, by adjusting the shape of the U-shaped groove of the connecting seat and increasing the platform where the drill bit enters the hole, the positioning accuracy during drilling can be ensured.

[0024]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com