Flat buckle template

A template and flat plate technology, applied in the direction of transportation, packaging, conveyors, etc., can solve the problem of inaccurate positioning, and achieve the effect of accurate positioning and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

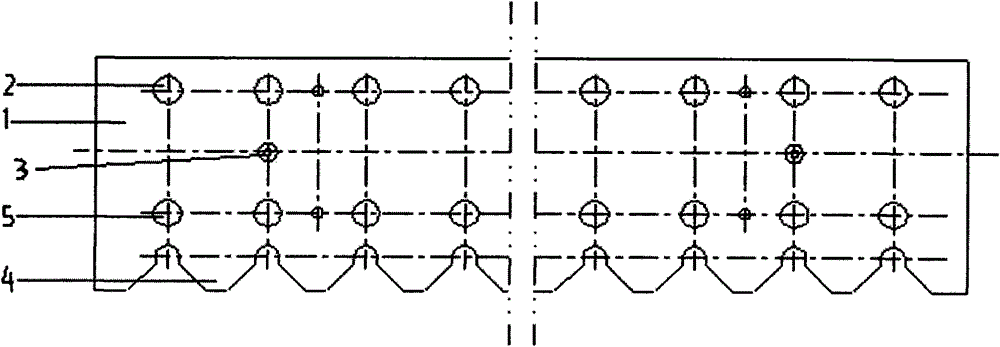

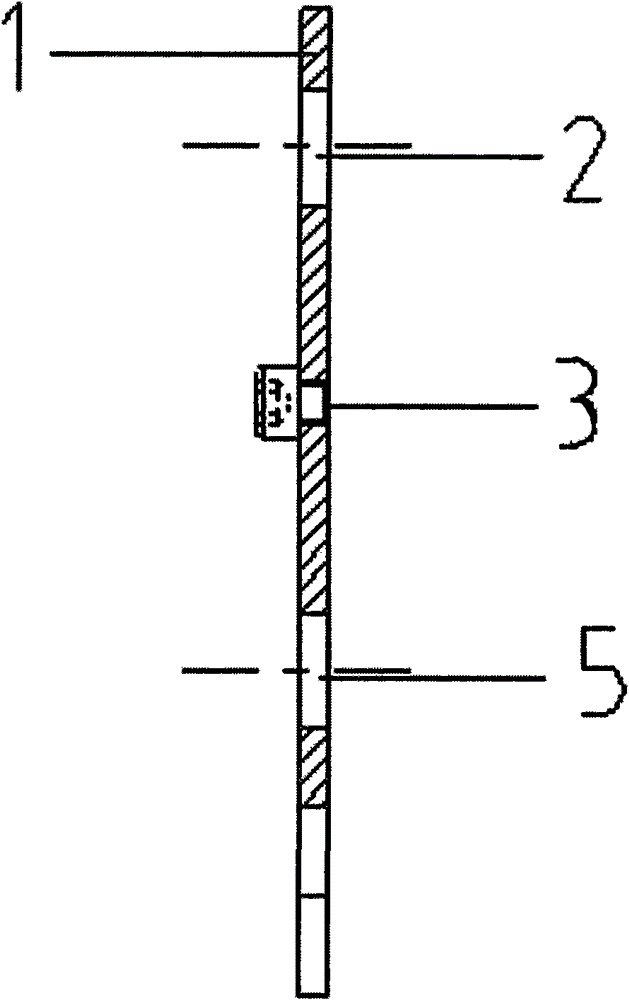

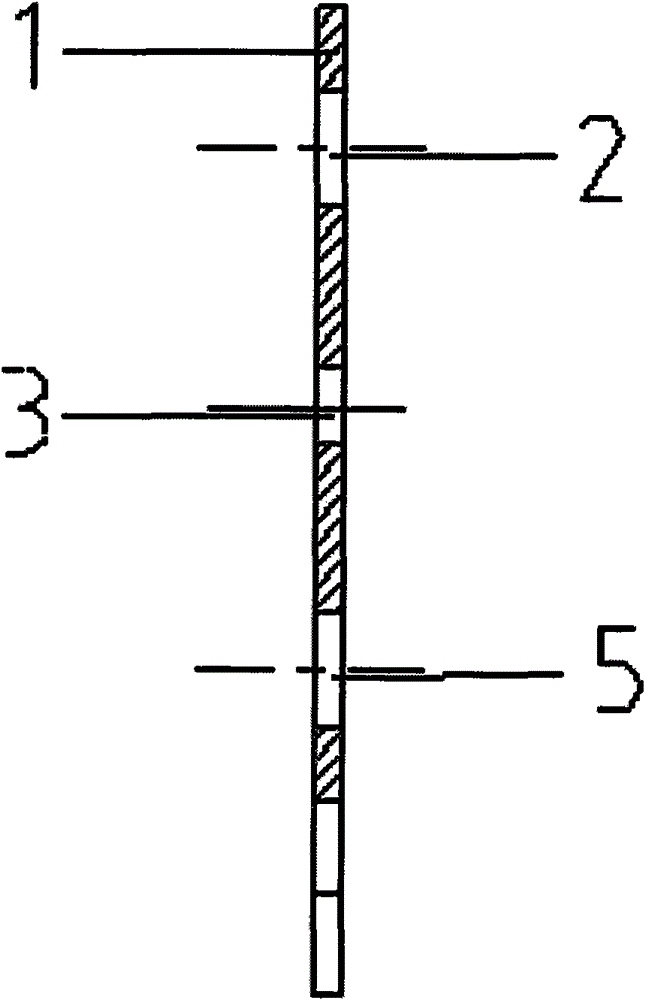

[0012] like figure 1 and figure 2 As shown, the flat plate formwork of the present invention is composed of a metal plate 1, wherein the metal plate 1 is rectangular, one side of the metal plate 1 is zigzag, and the metal plate 1 is provided with a first circular hole group and A second round hole group, the first round hole group is provided with more than two first round holes 2, and the first round holes 2 are arranged in a direction parallel to the sawtooth edge of the metal plate 1, so The second circular hole group is provided with a second circular hole 5 equal in number to the first circular hole 2, and the second circular hole 5 is arranged along a direction parallel to the sawtooth edge of the metal plate 1 and is aligned with the first circular hole. 2 in a rectangular array, the bottom of any one of the sawtooth 4 is a semicircle, and the centers of any one of the semicircles are respectively located on the longitudinal connection line between the center of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com