Metal powder processing system for 3D printing equipment

A 3D printing and processing system technology, applied in the direction of improving process efficiency, additive processing, improving energy efficiency, etc., can solve the problems of cumbersome operation steps of the sealing ring, unable to effectively ensure the consistency of the sealing around the sealing ring, etc., to improve printing Forming efficiency and quality of printed products, the effect of improving printing forming efficiency and improving printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Such as Figures 1 to 6 As shown, a metal powder processing system for 3D printing equipment includes a powder tank, a powder feeding device and a powder spreading device, and the powder tank, powder feeding device and powder spreading device are connected in sequence through a powder feeding pipe.

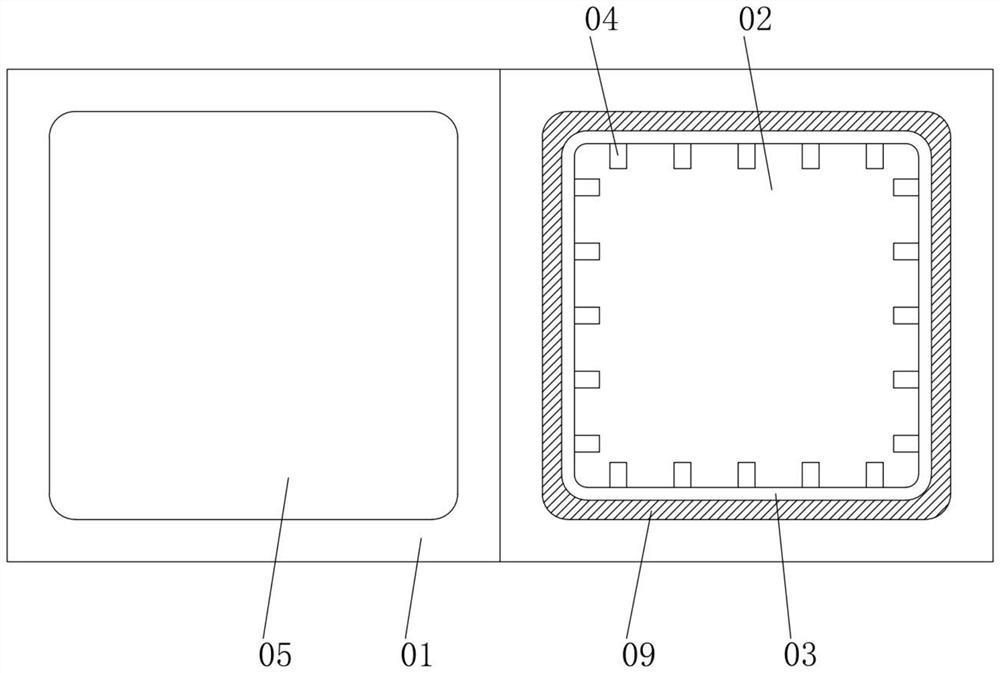

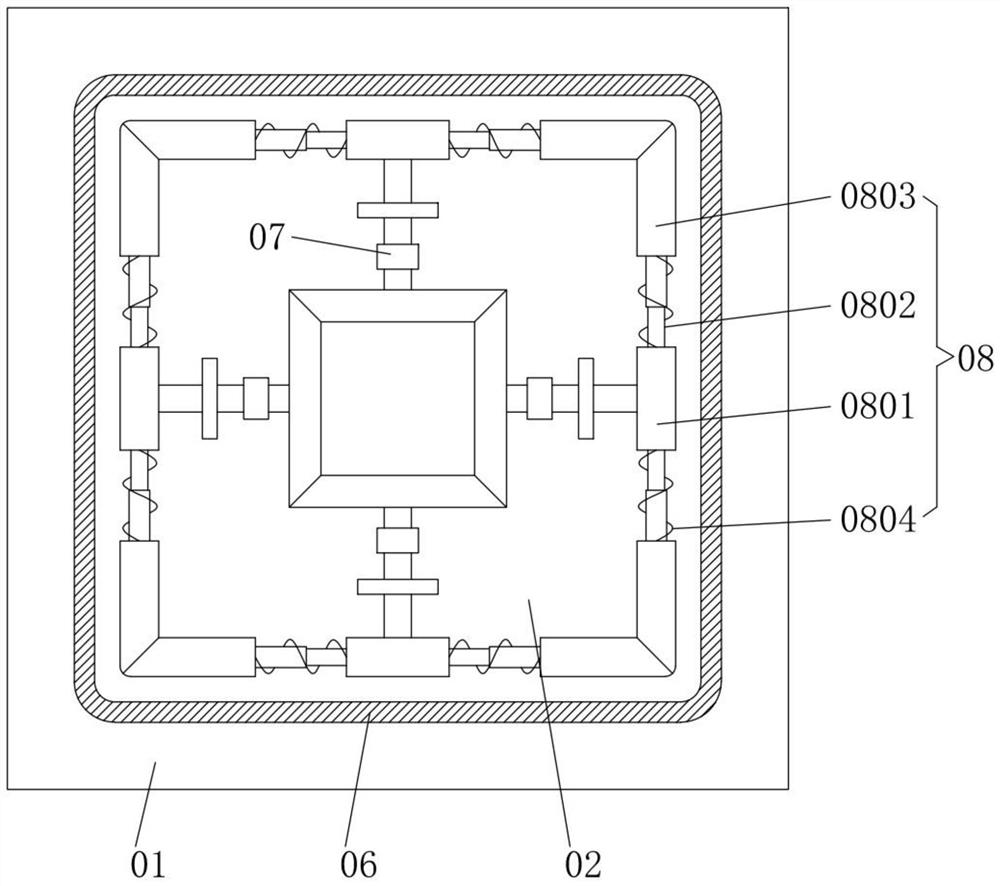

[0054] The powder cylinder includes a cylinder body, a piston, a felt, a spring plunger, a cover plate and a sealing ring, the piston is slidably connected with the inner wall of the cylinder body, the cover plate is fixedly connected with the top of the piston, and the felt is located between the piston and The cover plates are in close contact with the inner wall of the cylinder body. The sealing ring is arranged at the bottom of the piston and closely adheres to the inner wall of the cylinder body. The bottom of the piston is provided with several rotating assemblies. The components are sequentially connected by transmission, and several of the rotating components are th...

Embodiment 2

[0057] Such as Figures 1 to 6 As shown, a metal powder processing system for 3D printing equipment includes a powder tank, a powder feeding device and a powder spreading device, and the powder tank, powder feeding device and powder spreading device are connected in sequence through a powder feeding pipe.

[0058] The powder feeding device of the present invention has a specific structure such as Figure 5 with Image 6 As shown, it includes a temporary storage box and a controller, and the temporary storage box is respectively provided with a feed pipe and a discharge pipe. According to needs, the feed pipe and the discharge pipe can be arranged on the end surface or the outer surface of the temporary storage box Among them, it is best to be arranged on the end face at the same time; the inlet end of the feed pipe is airtightly connected with the powder storage device, and the outlet end of the discharge pipe is airtightly connected with the powder device; There is a transp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com