Automatic cover opening and closing type liquid multifunctional cleaning machine

An automatic switch and multi-functional technology, applied in the field of cleaning machines, can solve problems such as inconvenient cleaning, clogging of pipeline circulation pumps, hidden safety hazards, etc., and achieve the effects of convenient fixed operation, avoiding blockage, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

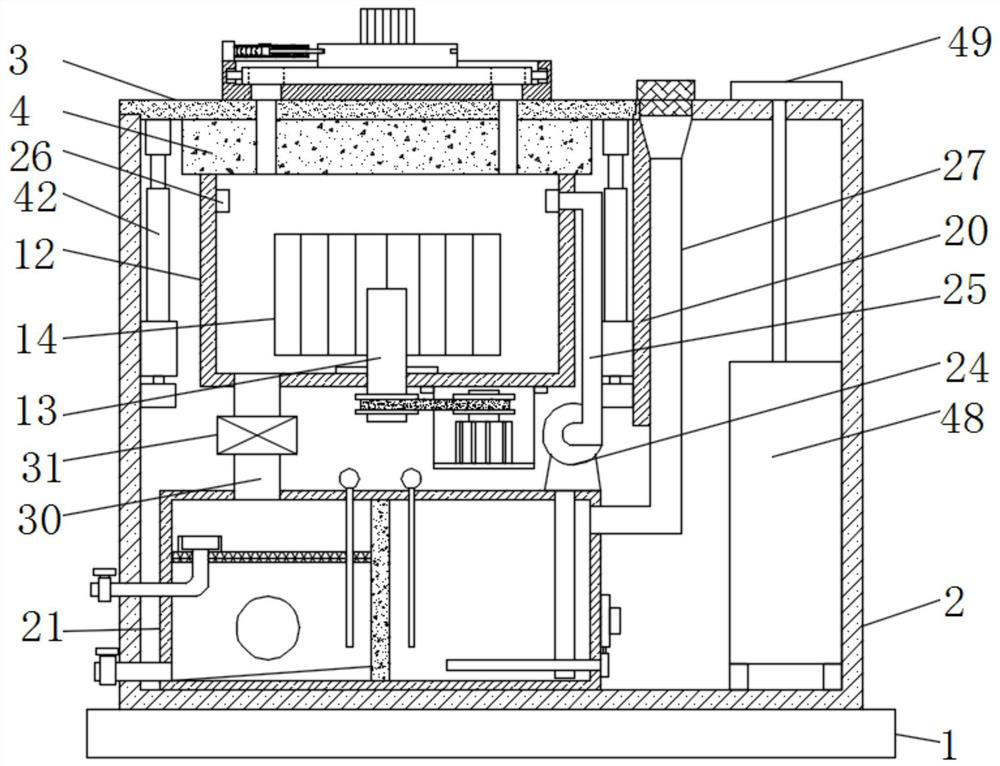

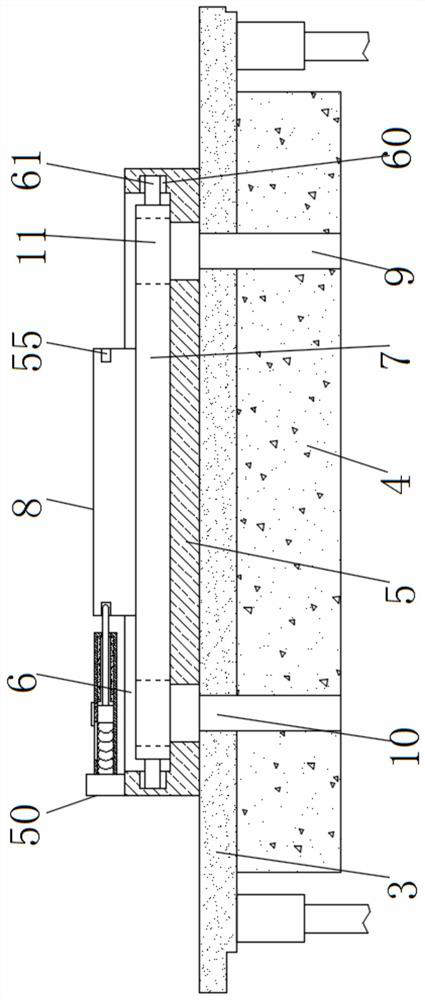

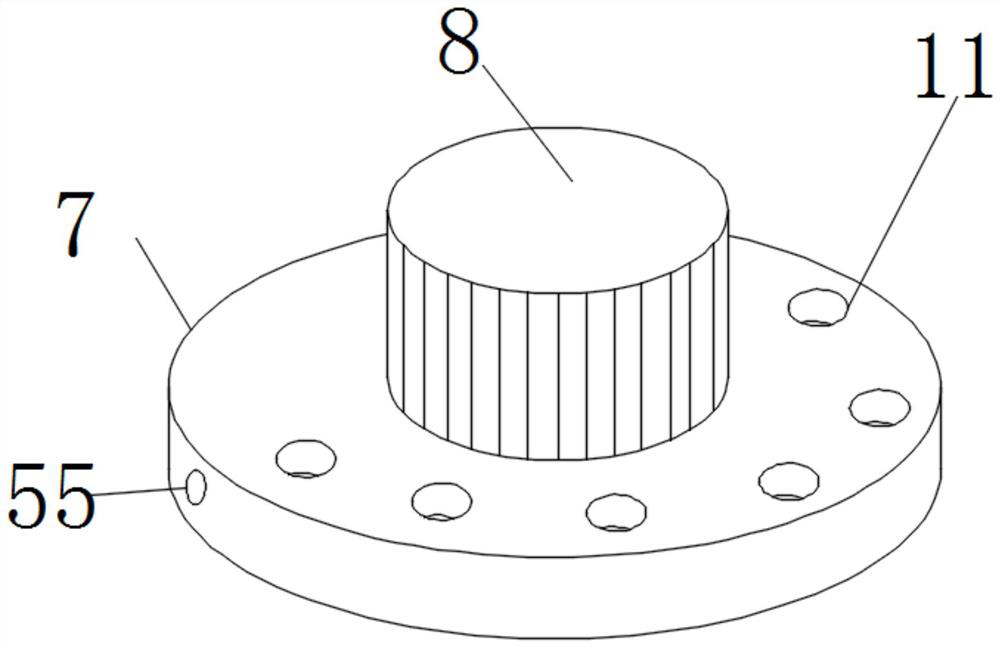

[0038] see Figure 1-12 According to an embodiment of the present invention, a liquid multi-function cleaning machine with an automatic switch cover includes a bottom plate 1, the top of the bottom plate 1 is fixedly connected with a box body 2, and the top hinge of the box body 2 is connected with a cover plate 3 , the bottom of the cover plate 3 is fixedly connected with a sealing plate 4, the top of the cover plate 3 is fixedly connected with a fixed plate 5, the top of the fixed plate 5 has a groove 6, and the inside of the groove 6 is provided There is a shielding plate 7, the shielding plate 7 is matched with the groove 6, the top of the shielding plate 7 is fixedly connected with a rotating block 8, and the rotating block 8 is provided with anti-slip lines;

[0039] One side of the sealing plate 4 is provided with a plurality of circular holes 9, and the surface of the cover plate 3 is provided with a circular hole 10 close to the circular hole 9, and the circular hole ...

Embodiment 2

[0045] see figure 1 and Figure 9 , the telescoping mechanism includes a hinge bracket 40, an explosion-proof motor 2 41, an electric push rod 42, a detection piece 43, an in-position detection sensor 44 and a hinge bracket 2 45, and the support plate 20 is fixedly connected to the inside of the box body 2 with Hinge support one 40, described hinge support one 40 is hingedly connected with the bottom of electric push rod 42, and the power end of described electric push rod 42 is connected with the output end of explosion-proof motor two 41, and the fixed end side of described electric push rod 42 The wall is fixedly connected with an in-position detection sensor 44, and the top of the movable end of the electric push rod 42 is fixedly connected with a detection sheet 43, and the detection sheet 43 is matched with the in-position detection sensor 44, and the top of the electric push rod 42 passes through The second hinge bracket 45 is movably connected with the cover plate 3 ,...

Embodiment 3

[0047] see figure 1 , the control mechanism includes an explosion-proof controller 48 and a control panel 49, an explosion-proof controller 48 is fixed at the bottom of one side of the box body 2, and the explosion-proof controller 48 is electrically connected with the control panel 49, and the control panel 49 Fixed on the top of the box body 2, the explosion-proof motor one 19, explosion-proof motor two 41, circulation pump 24, temperature control switch 29, liquid level sensor one 46, liquid level sensor two 47, position detection sensor 44 and solenoid valve 31 are electrically connected with the explosion-proof controller 48, and the control mechanism is used to control the electronic devices on the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com