Method for wiping AF oil stains on front of 3D watch cover of step product

A stepped surface and 3D technology, applied in the field of cover surface cleaning, can solve the problems of poor anti-penetration performance, reduction, low efficiency and production capacity, etc., and achieve the effect of guaranteed performance, good decontamination effect, and good softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further specifically described below through specific embodiments and accompanying drawings, but the present invention is not limited to these embodiments.

[0025] to combine figure 1 and figure 2 As shown, the method of wiping the AF oil stain on the front of the 3D cover of the step product includes the following treatment methods:

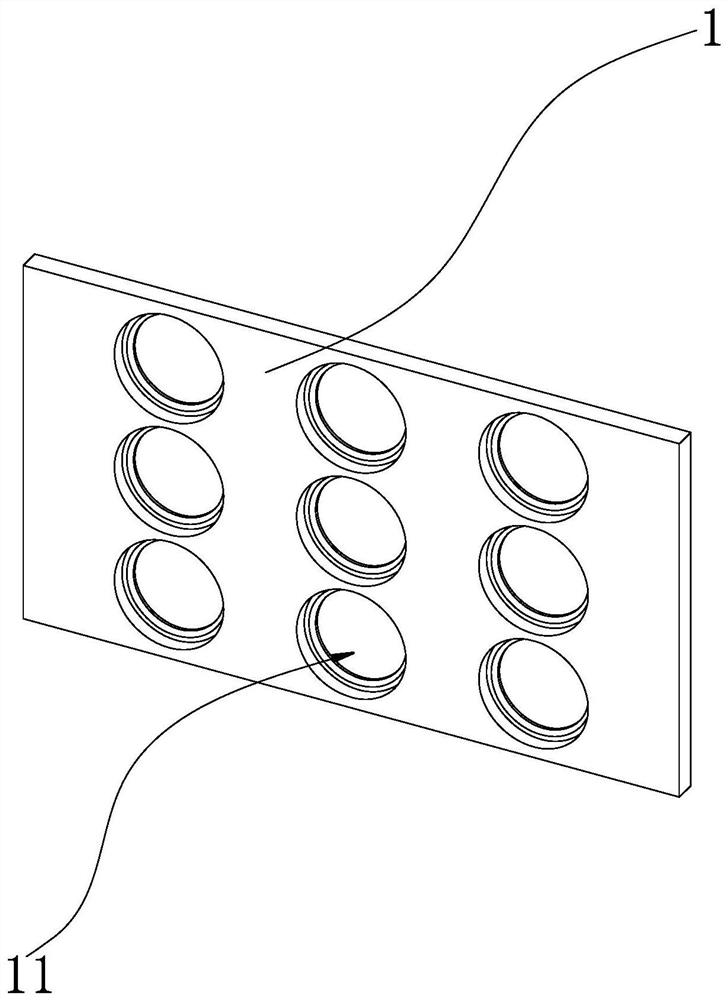

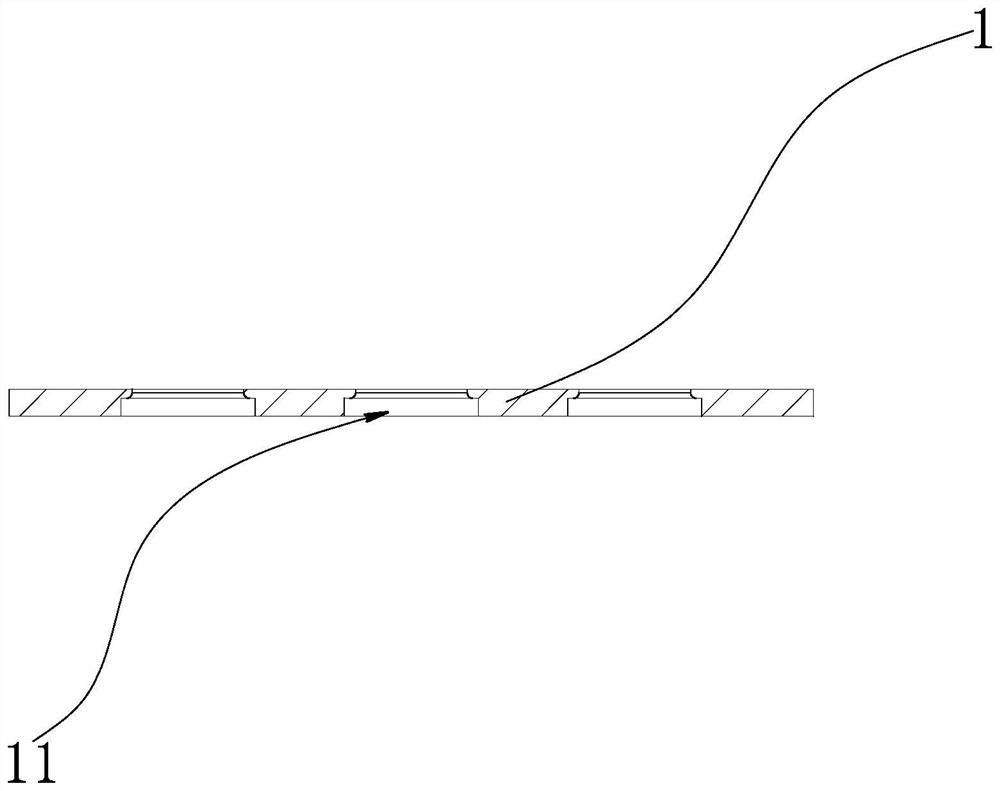

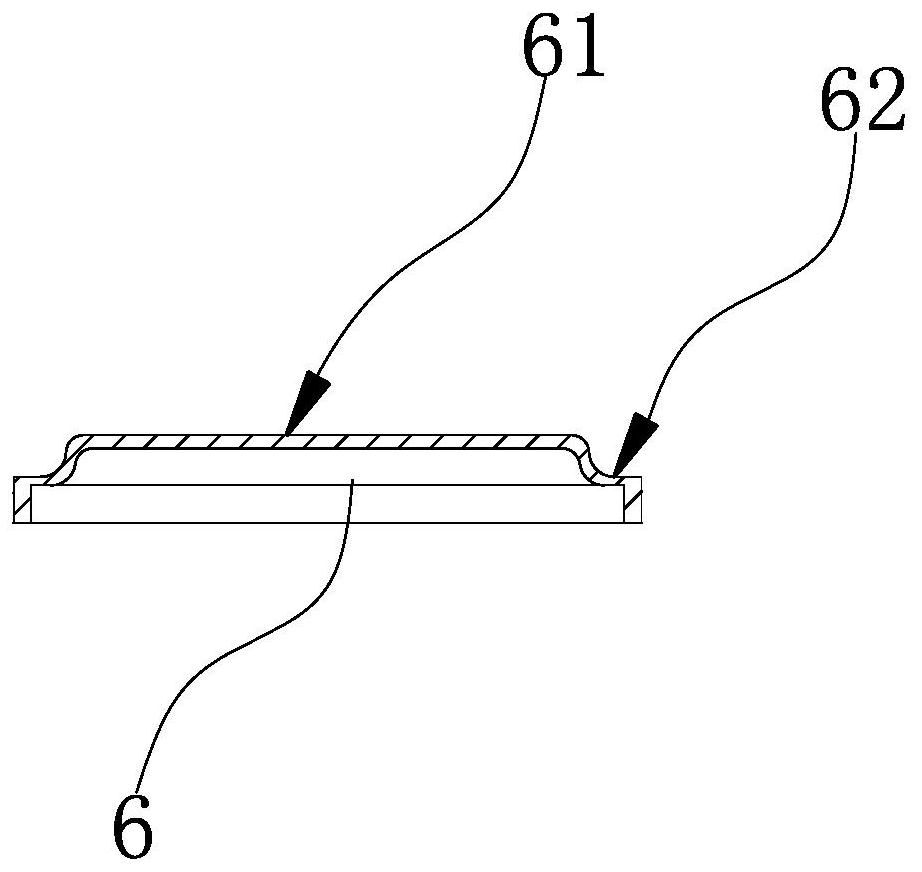

[0026] The 3D watch cover 6 of this stepped product includes a stepped surface 62 and a window area 61. The structural characteristics of the 3D watch cover 6 are conventional designs, and the more important thing is the specific wiping method. Specifically, the front of the window area 61 is plated. The 3D watch cover 6 of the AF film is placed on the jig 1 that can expose the front of the window area 61 of the 3D watch cover 6 and can block the step surface 62, and then put the above-mentioned 3D watch cover 6 through the automatic conveying system 2 The jig 1 is transported t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com