PBT resin with low dyne value and preparation method thereof

A technology of PBT resin and dyne value, which is applied in the field of PBT resin with low dyne value and its preparation, can solve the problems of high surface tension of PBT, difficult target separation, limited reduction effect, etc., and achieve reduction of surface crystal content, Effect of increasing reactivity and reducing crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

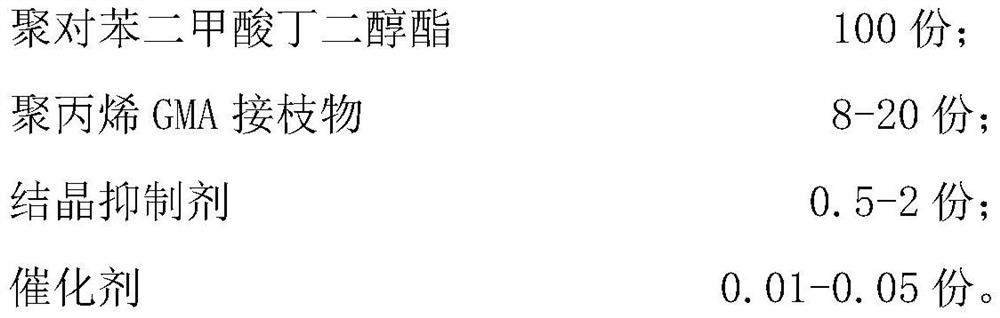

[0039] A kind of PBT resin of low dyne value, comprises each component of following parts by weight:

[0040]

[0041] The preparation method of PBT resin is as follows:

[0042] (1) Weigh each component by weight ratio: polybutylene terephthalate (PBT), polypropylene GMA graft, crystallization inhibitor, catalyst.

[0043] (2) After each component in the step (1) is fully mixed through a high-speed mixer, extrude and granulate the PBT resin to obtain low dyne value by a twin-screw extruder; the rotating speed of the twin-screw extruder is 450 -600 rev / min, the temperature is 230-240°C.

[0044] The prepared PBT resin was injection molded into a standard test sample with a size of 10cm×10cm×2cm, and a mark was drawn on the sample with a dyne pen, and the dyne value of the sample was tested according to the shrinkage of the mark.

Embodiment 2

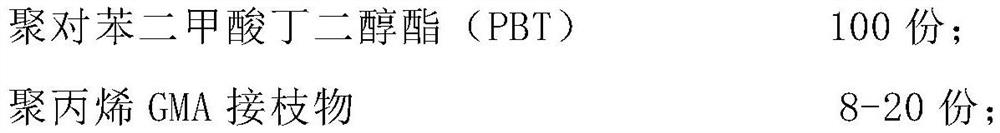

[0046] A kind of PBT resin of low dyne value, comprises each component of following parts by weight:

[0047]

[0048]

[0049] The preparation method is the same as in Example 1.

[0050] The prepared PBT resin was injection molded into a standard test sample with a size of 10cm×10cm×2cm, and a mark was drawn on the sample with a dyne pen, and the dyne value of the sample was tested according to the shrinkage of the mark.

Embodiment 3

[0052] A kind of PBT resin of low dyne value, comprises each component of following parts by weight:

[0053]

[0054] The preparation method is the same as in Example 1.

[0055] The prepared PBT resin was injection molded into a standard test sample with a size of 10cm×10cm×2cm, and a mark was drawn on the sample with a dyne pen, and the dyne value of the sample was tested according to the shrinkage of the mark.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com