Sound absorption bandwidth increasing type micro-perforated plate sound absorber based on piezoelectric material

A technology of micro-perforated plate and piezoelectric material, applied in the field of acoustics, can solve the problems of multi-layer composite structure increasing structural complexity, increasing material and processing cost, unable to play the micro-perforated plate, etc., achieving good application value and application prospect, The effect of reducing self-sound interference and improving sound absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

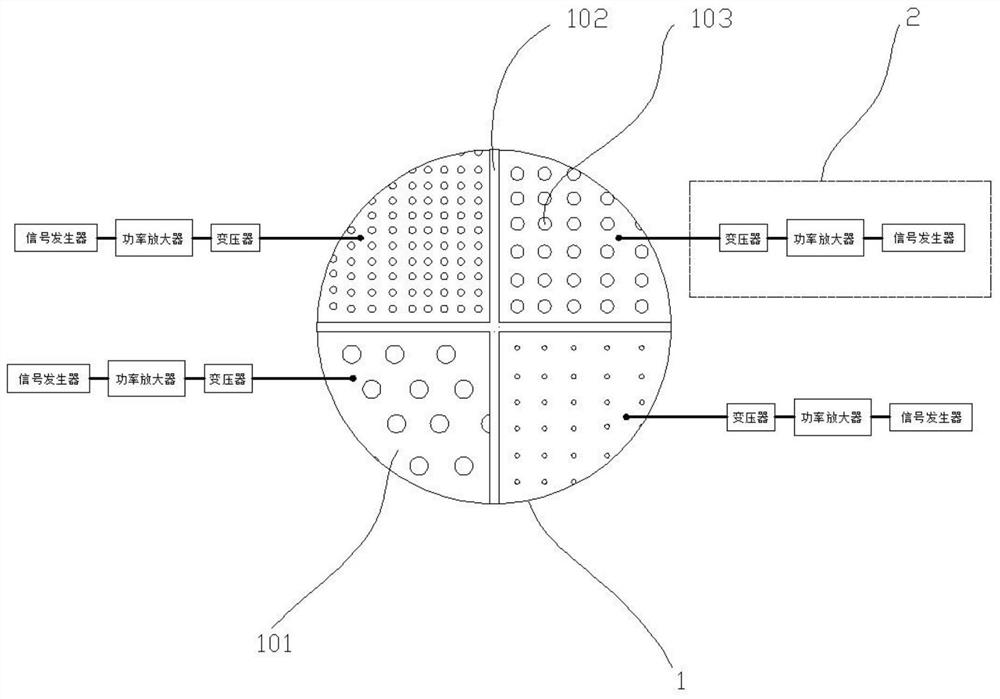

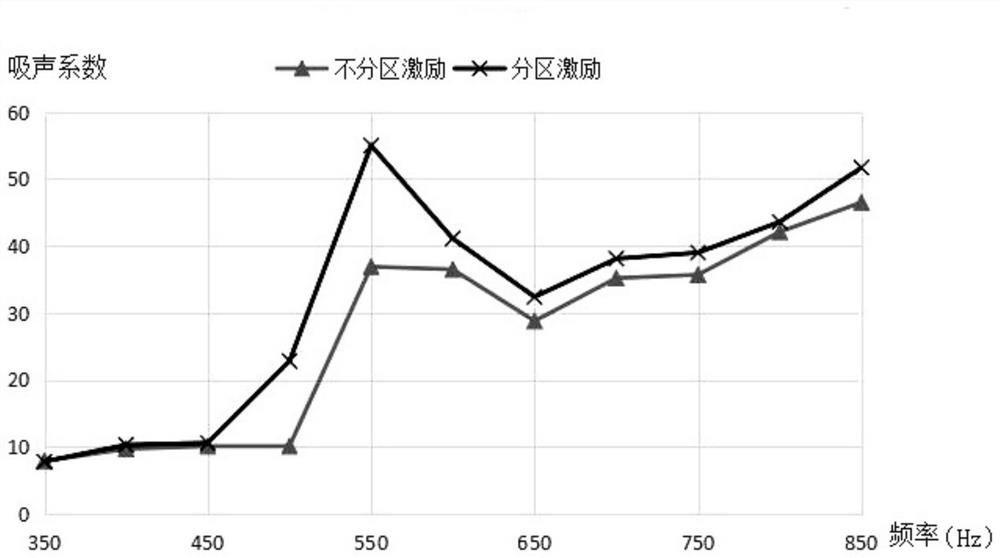

Embodiment 1

[0017] see figure 1 , the present invention provides an embodiment of a micro perforated plate sound absorber with increased sound absorption bandwidth based on piezoelectric materials, including a micro perforated plate sound absorber, and the micro perforated plate sound absorber is a Helmholtz resonator The structure includes a piezoelectric micro-perforated plate 1 made of polyvinylidene fluoride (PVDF), a rigid wall, and a back cavity. 101 are respectively plated with aluminum electrode coating to form electrode regions. Each region 101 is voltage-excited by its own excitation circuit 2. The number of voltage excitation applied to each region 101 is 1. The excitation circuit 2 includes a DC power supply and a power amplifier. , a transformer and a signal generator, one end of the transformer is connected to the electrode area of the piezoelectric micro-perforated plate 1, and the other end is connected to a respective power amplifier, and the power amplifier is input by...

Embodiment 2

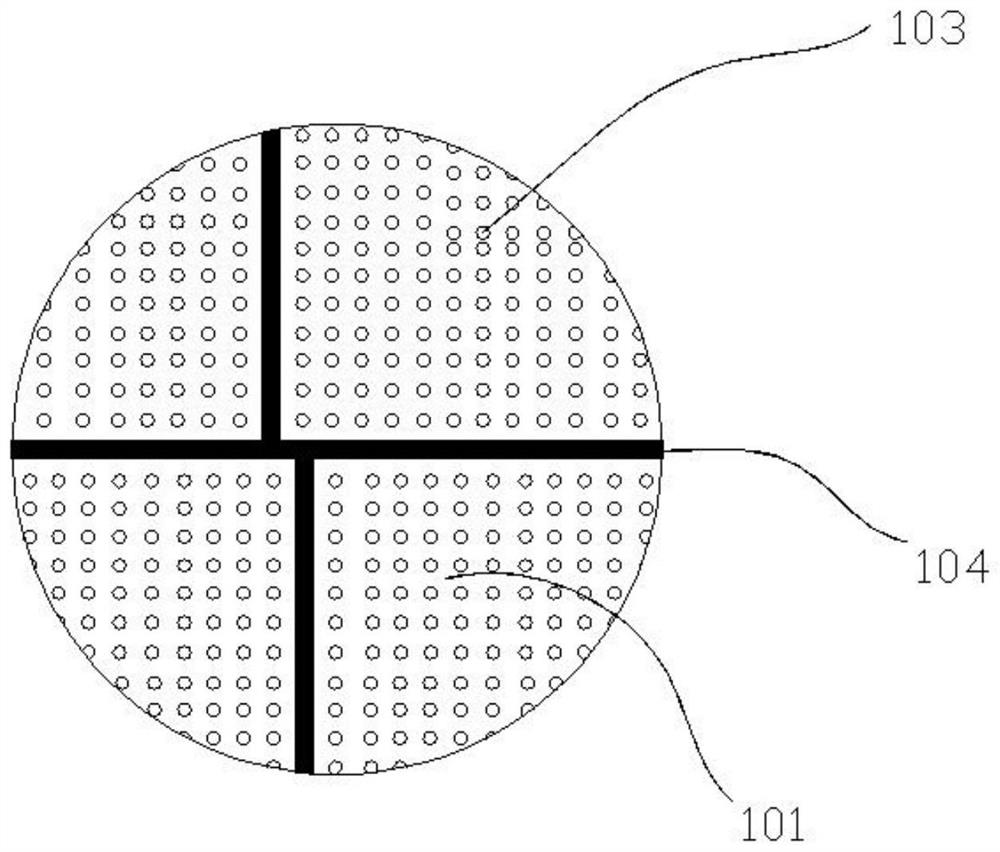

[0025] see figure 2 , the present invention provides an embodiment of a micro perforated plate sound absorber with increased sound absorption bandwidth based on piezoelectric materials, including a micro perforated plate sound absorber, and the micro perforated plate sound absorber is a Helmholtz resonator The structure includes a piezoelectric micro-perforated plate 1 made of polyvinylidene fluoride (PVDF), a rigid wall, and a back cavity. 101 are respectively plated with aluminum electrode coating to form electrode regions, and each region is excited by its own excitation circuit 2, and the number of voltage excitation applied to each region 101 is 1, and the excitation circuit 2 includes a DC power supply, a power amplifier, A transformer and a signal generator, one end of the transformer is connected to the electrode area of the piezoelectric micro-perforated plate 1, and the other end is connected to their respective power amplifiers, the power amplifiers are input by ...

Embodiment 3

[0033] see figure 1 , the present invention provides an embodiment of a micro perforated plate sound absorber with increased sound absorption bandwidth based on piezoelectric materials, including a micro perforated plate sound absorber, and the micro perforated plate sound absorber is a Helmholtz resonator The structure includes a piezoelectric micro-perforated plate 1 made of polyvinylidene fluoride (PVDF), a rigid wall, and a back cavity. 101 are respectively plated with aluminum electrode coating to form electrode regions. Each region 101 is voltage-excited by its own excitation circuit 2. The number of voltage excitation applied to each region is 1. The excitation circuit 2 includes a DC power supply, a power amplifier, A transformer and a signal generator, one end of the transformer is connected to the electrode area of the piezoelectric micro-perforated plate 1, and the other end is connected to their respective power amplifiers, the power amplifiers are input by the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com