Triangular control mechanism and its multi-station weaving method

A control mechanism and multi-station technology, applied in weft knitting, knitting, textiles and papermaking, etc., can solve the problems of long reciprocating stroke of the machine head, error of triangle action, affecting delivery time and cost, etc., to achieve a large increase in output , Eliminate the root cause of the failure and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

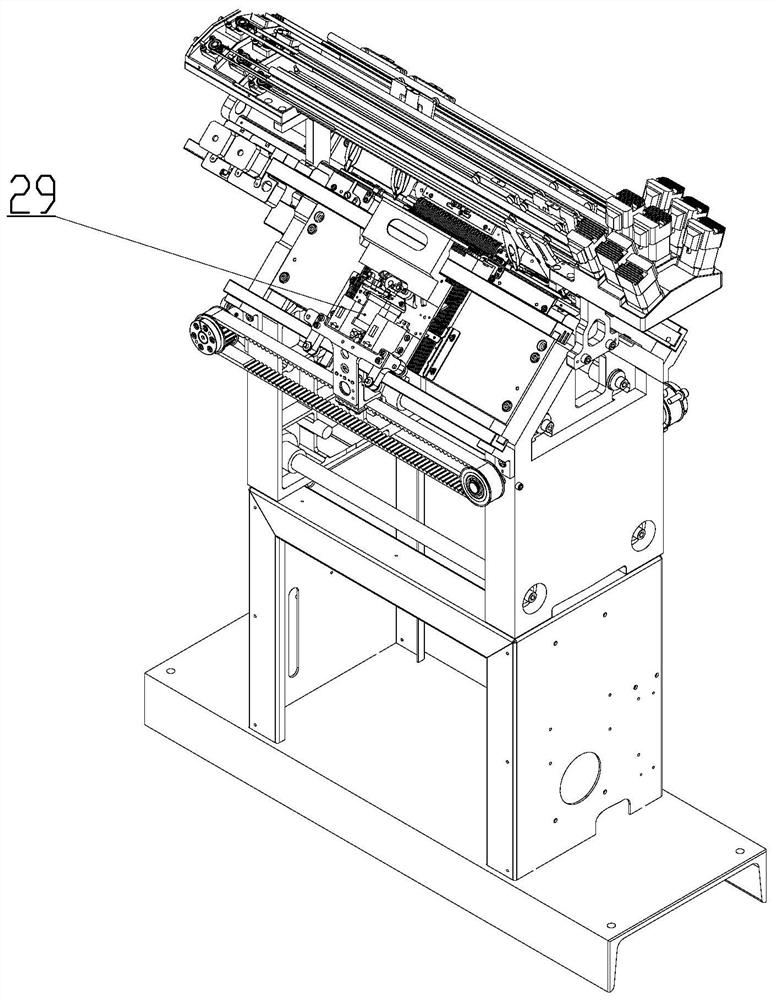

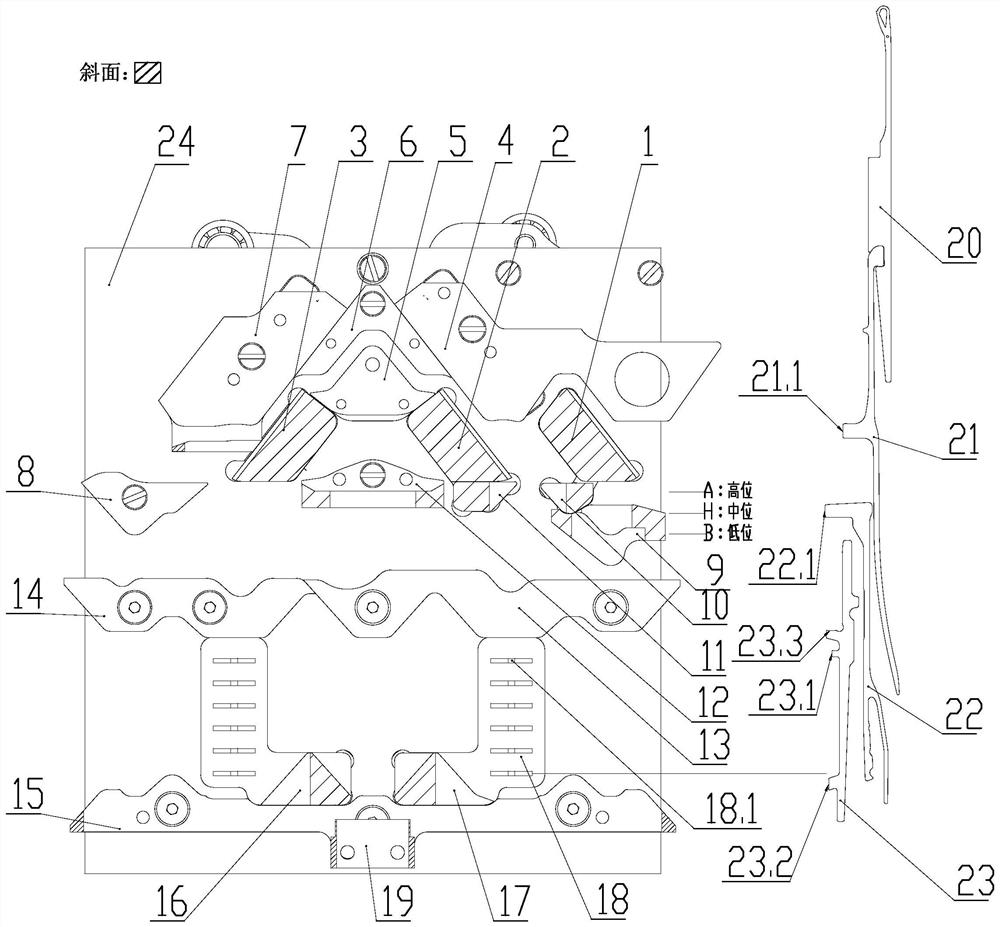

[0083] This embodiment proposes a triangular control mechanism, such as figure 2 As shown, the triangular control mechanism can be installed in such as figure 1 In the machine head 29 of the shown smart glove machine, the machine head 29 is symmetrically installed on the front and rear needle beds, and runs left and right. The machine head 29 described in this embodiment is unfolded by the rear machine head knitting system. The needle groups mentioned in the text are as figure 2 As shown on the right, it includes a needle jack 21, an intermediate piece 22, and a selector jack 23 from top to bottom. The needle jack 21 is nested on the crochet needle 20, and the needle movement is controlled by a triangular track (such as a knitting track, a tuck track) track, and can be pressed into the needle bed by the middle piece 22 and the cam; figure 2 As shown, A in the figure represents the high position, H represents the middle position, and B represents the low position), when ...

Embodiment 2

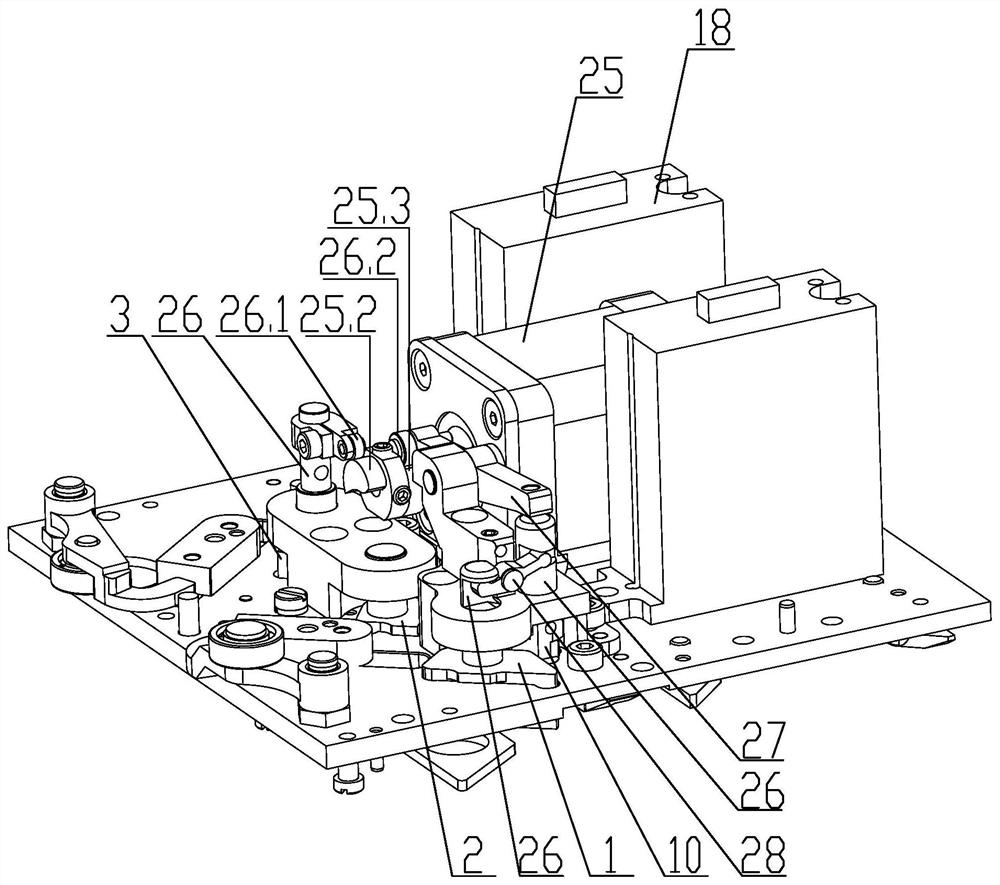

[0123] The principle of this embodiment is the same as that of Embodiment 1, the difference is that the needle selection homing triangle 19 of this embodiment is movable in translation, such as Figures 12 to 13 As shown, a slide bar 24.1 is provided on the triangular base plate 24, and one end of the needle selection homing cam 19 is located at the front of the triangular base plate 24 to realize the inductive effect of needle selection, and the other end is a translation block 19.3 located at the back of the triangular base plate 24, and the translation The block 19.3 is provided with a through hole for passing through the slide bar 24.1, the end of the slide bar 24.1 is fixed with a pin 19.4 and a spacer 19.7 to limit the translation block 19.3, and a spring is set between the spacer 19.7 and the translation block 19.3 24.2 Realize the reset of the moving block. The output shaft located in the needle selection area is provided with homing wheel 25.7. The cross section of tr...

Embodiment 3

[0125] The principle of this embodiment is the same as that of Embodiment 1, the difference is that the needle selection homing cam 19 of this embodiment is a swingable activity, such as Figures 14 to 16As shown, a homing wheel 25.7 is provided on the rotating shaft 25.1 located in the needle selection area. The needle selection homing cam 19 includes a rotating shaft 19.5 that is rotatably connected to the triangular bottom plate 24. The needle selection homing cam 19 is provided with a convex direction. The convex portion 19.6 of the homing wheel 25.7, the homing wheel 25.7 is provided with a groove 25.9 for accommodating the convex portion 19.6, the spring 24.2 on the needle selection homing cam 19 is a torsion spring sleeved on the rotating shaft 19.5, Through the rotating shaft 19.5, the needle selection homing cam 19 can swing between angles close to and away from the triangular bottom plate 24. Such as Figure 15 As shown, since the convex portion 19.6 does not corres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com