Biomass-based adhesive filler, adhesive, plywood, and preparation method and application

A technology based on adhesive and biomass, used in adhesive additives, adhesives, polymer adhesive additives, etc., can solve the problems of high formaldehyde emission, low plywood strength, threat to human health, etc., and reduce formaldehyde emission. Quantity, low cost, and improved bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

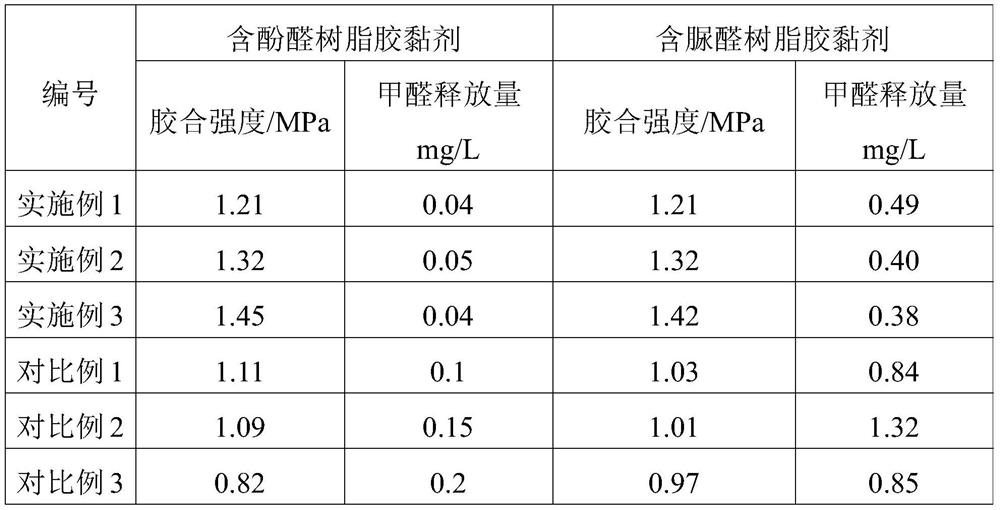

Examples

Embodiment 1

[0047] 1. Preparation of biomass-based adhesive filler

[0048] (1) 30 parts of biological extracts and 50 parts of montmorillonite were uniformly mixed in a mixer, the mixing speed was 150rpm, and the mixing time was 10min to obtain material A;

[0049] (2) Mix 5 parts of calcium carbonate, 5 parts of sodium carboxymethyl cellulose and 0.5 part of guar gum in another mixer, the mixing speed is 150 rpm, and the mixing time is 10 min to obtain material B;

[0050] (3) Material A and material B were mixed for 5 minutes at a rotational speed of 80 rpm, and finally a biomass-based adhesive filler was obtained.

[0051] 2. Preparation of phenolic resin adhesive

[0052] Mix 27 parts of the biomass-based adhesive filler prepared above with 100% phenolic resin, the mixing speed is 120 rpm, and the mixing time is 5 minutes to prepare the phenolic resin-containing adhesive.

[0053] 3. Preparation of urea-formaldehyde resin adhesive

[0054] Mix 27 parts of the biomass-based adhesive ...

Embodiment 2

[0056] 1. Preparation of biomass-based adhesive filler

[0057] (1) 40 parts of biological extracts and 30 parts of montmorillonite were uniformly mixed in a mixer, the mixing speed was 60 rpm, and the mixing time was 60 minutes to obtain material A;

[0058] (2) 7 parts of calcium carbonate, 8 parts of sodium carboxymethylcellulose and 1.5 parts of guar gum were mixed uniformly in another mixer, the mixing speed was 60 rpm, and the mixing time was 60 min to obtain material B;

[0059] (3) Material A and material B were mixed for 5 minutes at a rotational speed of 90 rpm, and finally a biomass-based adhesive filler was obtained.

[0060] 2. Preparation of phenolic resin adhesive

[0061] Mix 27 parts of the above-prepared biomass-based adhesive filler with 100% phenolic resin, the mixing speed is 100 rpm, and the mixing time is 6 minutes to prepare the phenolic resin-containing adhesive.

[0062] 3. Preparation of urea-formaldehyde resin adhesive

[0063] Mix 27 parts of th...

Embodiment 3

[0065] 1. Preparation of biomass-based adhesive filler

[0066] (1) 60 parts of biological extracts and 20 parts of montmorillonite were uniformly mixed in a mixer, the mixing speed was 100 rpm, and the mixing time was 40 minutes to obtain material A;

[0067] (2) 10 parts of calcium carbonate, 10 parts of sodium carboxymethyl cellulose and 3 parts of guar gum were mixed uniformly in another mixer, the mixing speed was 100 rpm, and the mixing time was 40 minutes to obtain material B;

[0068] (3) Material A and material B were mixed for 8 minutes at a rotational speed of 60 rpm, and finally a biomass-based adhesive filler was obtained.

[0069] 2. Preparation of phenolic resin adhesive

[0070] Mix 27 parts of the biomass-based adhesive filler prepared above with 100% phenolic resin, the mixing speed is 80 rpm, and the mixing time is 8 minutes to prepare the phenolic resin-containing adhesive.

[0071] 3. Preparation of urea-formaldehyde resin adhesive

[0072] Mix 27 parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com