Microcapsule-filled sodium alginate-based hydrogel and preparation method thereof

A sodium alginate and microcapsule technology is applied in the field of microcapsule-filled sodium alginate-based hydrogel and its preparation, which can solve the problems of poor stability and low loading rate of hydrophobic functional substances, and achieves good structural stability, The method is simple and easy to implement, and the effect of controlled release is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

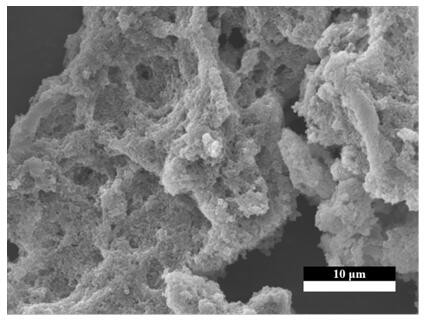

[0027] Step 1. Preparation of zein-based microcapsules:

[0028] Weigh 0.2 parts by mass of zein and add it to 10.0 parts by mass of 85% ethanol aqueous solution, then add 0.01 parts by mass of thymol and 0.01 parts by mass of polyoxyethylene lauryl ether, and stir for 2 h to prepare a mixed solution ; Then add 20 parts by mass of ultrapure water to the mixed system, and then remove the ethanol in the mixed system by rotary evaporation to obtain a zein-based microcapsule emulsion.

[0029] Step 2, preparing sodium alginate solution:

[0030] Weigh 0.1 parts by mass of sodium alginate into 50 parts by mass of water, stir for 6 hours in a water bath at 40°C until completely dissolved, and obtain a sodium alginate solution;

[0031] Step 3, preparation of microcapsule-filled sodium alginate-based hydrogel:

[0032] Take 0.1 mass part of zein microcapsule emulsion and add it to 1.0 mass part of sodium alginate solution, adjust the pH of the system to 6.5 with 0.1 mol / L NaOH and ...

Embodiment 2

[0034] Step 1. Preparation of zein-based microcapsules:

[0035] Weighed 0.2 parts by mass of zein and added it to 10.0 parts by mass of 85% ethanol aqueous solution, then added 0.05 parts by mass of mugwort essence and 0.06 parts by mass of Pluronic F127, and stirred for 2 h to prepare a mixed solution; 22 parts by mass of ultrapure water were added to the mixed system, and then the ethanol in the mixed system was removed by rotary evaporation to prepare a zein-based microcapsule emulsion.

[0036] Step 2, preparing sodium alginate solution:

[0037] Weigh 0.5 parts by mass of sodium alginate into 50 parts by mass of water, stir for 6 h in a water bath at 48°C until completely dissolved, and obtain a sodium alginate solution;

[0038] Step 3, preparation of microcapsule-filled sodium alginate-based hydrogel:

[0039] Get 0.5 parts by mass of zein microcapsule emulsion and add it to 1.0 parts by mass of sodium alginate solution, adjust the pH of the system to 6.5 with 0.1 mo...

Embodiment 3

[0041] Step 1. Preparation of zein-based microcapsules:

[0042] Weigh 0.2 parts by mass of zein and add it to 10.0 parts by mass of 85% ethanol aqueous solution, then add 0.10 parts by mass of eugenol and 0.10 parts by mass of Pluronic F127, and stir for 2 h to prepare a mixed solution; 25 parts by mass of ultrapure water was added to the mixed system, and then the ethanol in the mixed system was removed by rotary evaporation to prepare a zein-based microcapsule emulsion.

[0043] Step 2, preparing sodium alginate solution:

[0044] Weigh 1.0 parts by mass of sodium alginate and add it to 50 parts by mass of water, and stir for 6 hours in a water bath at 56°C until completely dissolved to obtain a sodium alginate solution;

[0045] Step 3, preparation of microcapsule-filled sodium alginate-based hydrogel:

[0046]Take 1.0 parts by mass of zein microcapsule emulsion and add it to 1.0 parts by mass of sodium alginate solution, adjust the pH of the system to 6.5 with 0.1 mol / L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com