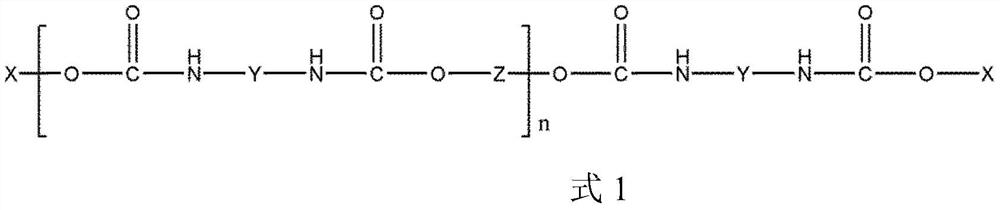

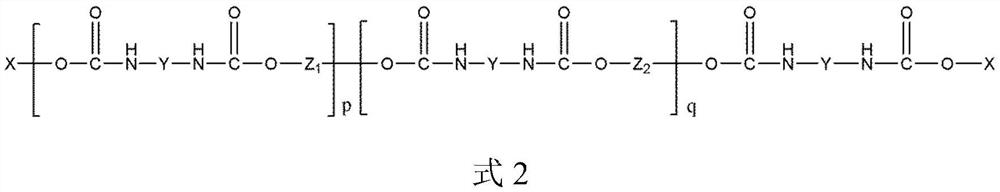

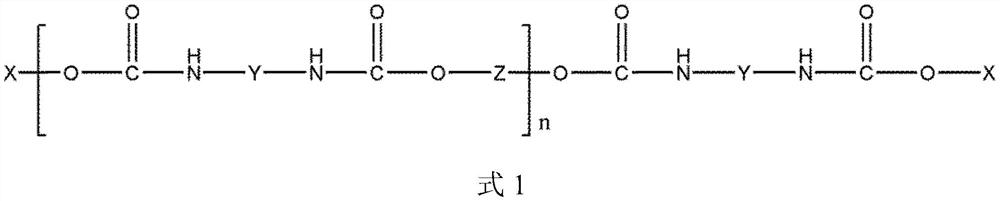

Urethane acrylate resin and preparation method thereof

A polyurethane acrylate and hydroxyalkyl acrylate technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve problems such as poor transparency of paint films, general elongation at break of photosensitive resins, and reduced strength of paint films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] Add TDI-80 into the reactor, start stirring, control the temperature of the reactor at 75°C, add LJP-3000EB for reaction, when the NCO content of the reaction system is 4.7%, add XCP-355, control the temperature of the reactor at 75°C Reaction, when the NCO content of the reaction system is 1.8%, add the pre-mixed MEHQ and hydroxyethyl acrylate into the reactor, stir well and then add T-12 for reaction, when the NCO content of the reaction system is 0.21%, end the reaction, Discharge.

Embodiment 2

[0080] Add TDI-80 into the reactor, start stirring, control the temperature of the reactor at 55°C, add XCP-355 for reaction, when the NCO content of the reaction system is 10.95%, add LJP-3000EB, control the temperature of the reactor at 75°C Reaction, when the NCO content of the reaction system is 1.82%, first add MEHQ, then add hydroxyethyl acrylate to the reactor, stir evenly and then add T-12 for reaction, when the NCO content of the reaction system is 0.26%, end the reaction, and material.

Embodiment 3

[0082] Add TDI-80 into the reactor, start stirring, control the temperature of the reactor at 65°C, add XCP-244 to react, when the NCO content of the reaction system is 3.58%, add XCP-500EB, control the temperature of the reactor at 75°C Reaction, when the NCO content of the reaction system is 1.63%, add the pre-mixed MEHQ and hydroxyethyl acrylate into the reactor, stir well and then add T-12 for reaction, when the NCO content of the reaction system is 0.23%, end the reaction, Discharge.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com