Solar enhanced sludge biological drying and gasified gas comprehensive treatment process and system

A technology of biological drying and comprehensive treatment, which is applied in the field of comprehensive treatment process and system of solar-enhanced sludge biological drying and gasification gas, can solve the problems of sludge reduction, stabilization and resource utilization, etc., and achieve The effect of improving the conversion efficiency of sludge resources and reducing pollutant emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings.

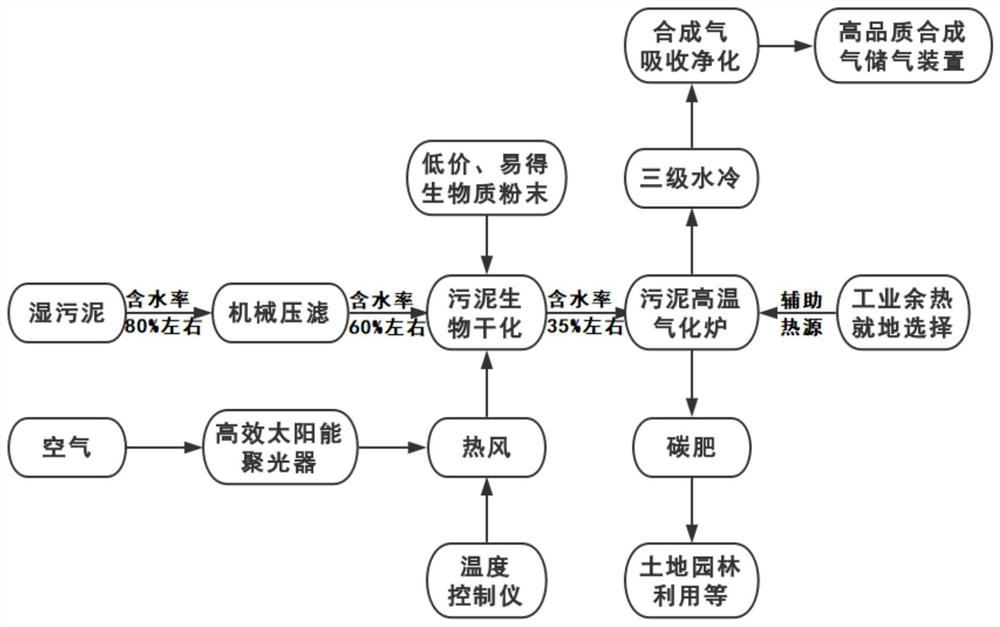

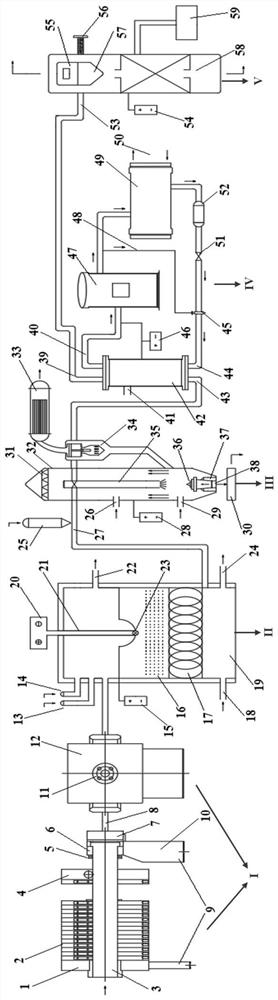

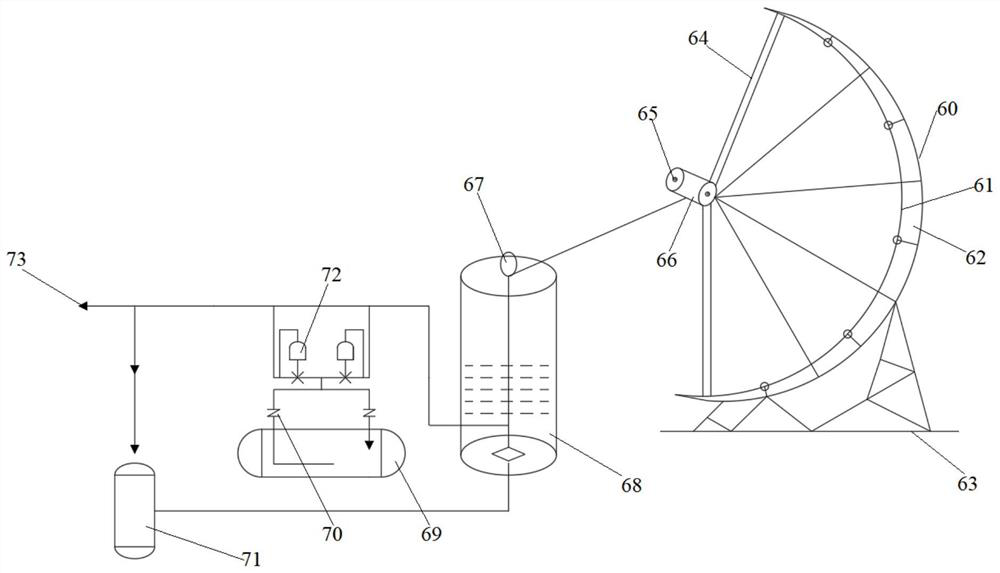

[0049] refer to Figure 1 ~ Figure 3 , a comprehensive treatment process of solar-enhanced sludge biological drying and gasification gas. First, mechanical press filtration is used to dehydrate the remaining sludge with a moisture content of about 80%, and the moisture content is reduced to 55-65%. The optical device provides a heat source to heat the air and pass it into the hot air to strengthen the biological drying of the sludge with green energy; and then use cheap and easy-to-obtain biomass powder to condition the wet sludge after pressing and biological drying for further dehydration treatment, and the moisture content is reduced to 30~ 40%; the addition of biomass powder takes into account the advantages of adjusting the characteristics of the sludge and improving the calorific value of the sludge itself. After the second dehydration, the sludge is sent to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com