New energy vehicle battery pack transfer protection device

A technology of new energy vehicles and protection devices, which is applied to battery pack components, transportation and packaging, circuits, etc., can solve problems such as heavy weight, battery jumping, battery body damage, etc. Strong, damage-avoiding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

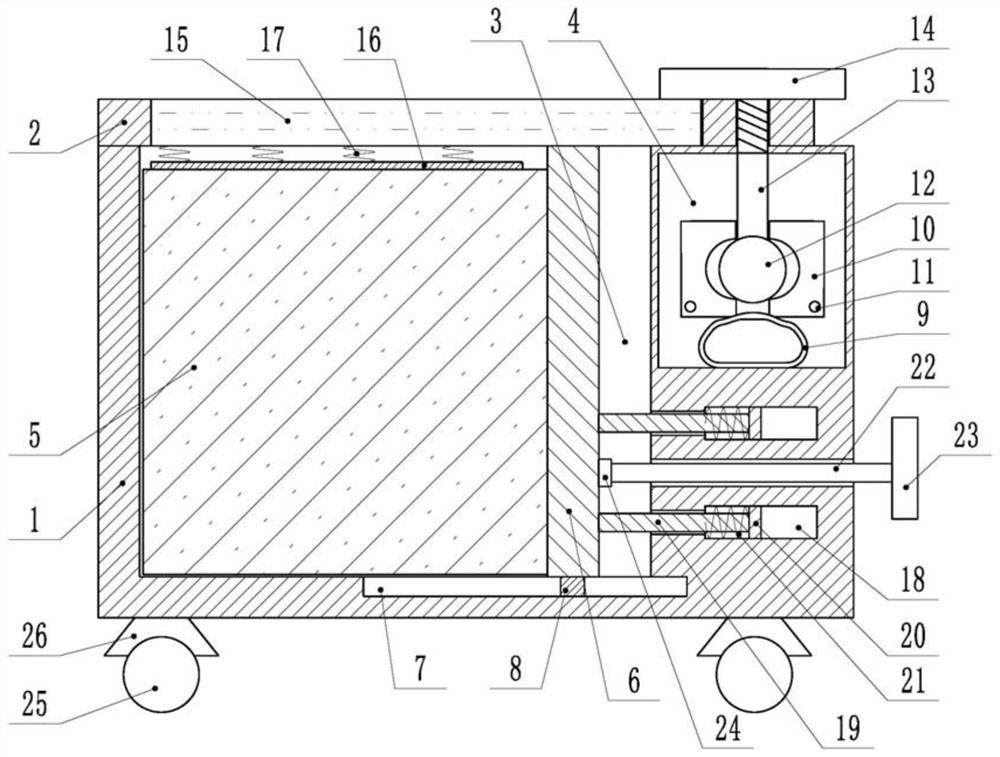

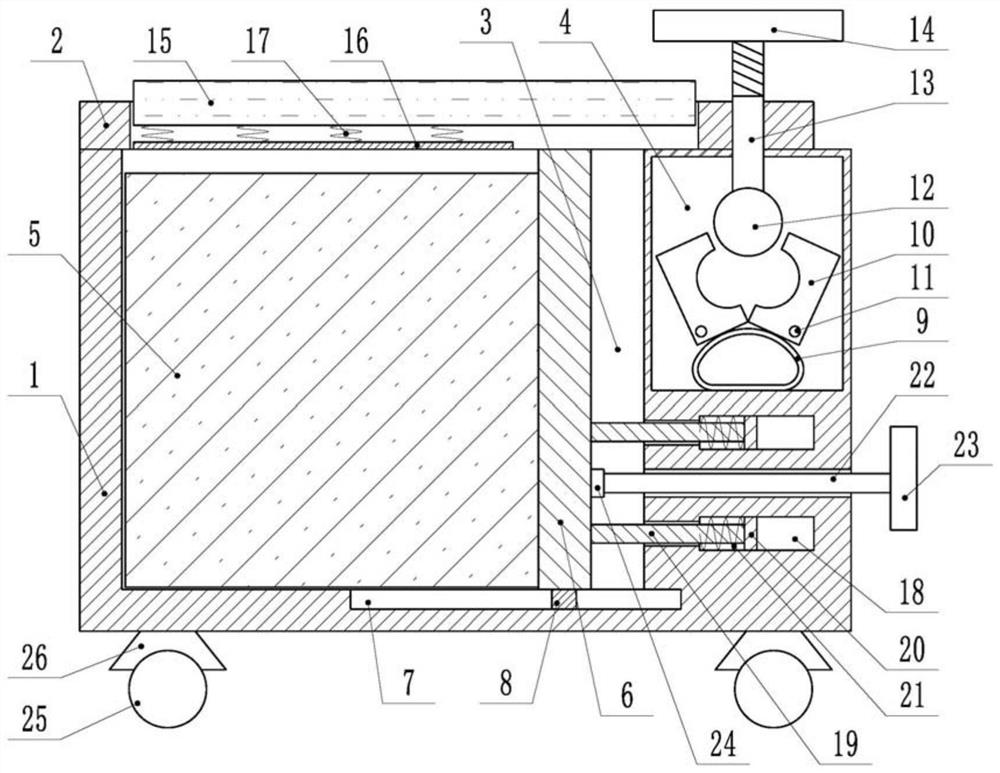

[0034] The embodiment is basically as attached figure 1 As shown: the new energy vehicle battery pack transfer protection device, including a storage box 1, and the top of the storage box 1 is provided with a cover plate 2. In this embodiment, the storage box 1 has a rectangular parallelepiped structure, and the inside of the storage box 1 is hollow, and the top of the storage box 1 It is an open end, and the cover plate 2 is a rectangular plate-shaped structure.

[0035] The right side of the storage box 1 is provided with an installation cavity 4, and the main compression unit for pressing the cover plate 2 is arranged in the installation cavity 4. The main compression unit includes an elastic plate 9 with elastic deformation, two clamping blocks 10 and a pushing As for the pusher for closing the clamping blocks 10 , the opposite sides of the two clamping blocks 10 are provided with circular arc grooves arranged symmetrically to each other, forming a complete circular shape ...

Embodiment 2

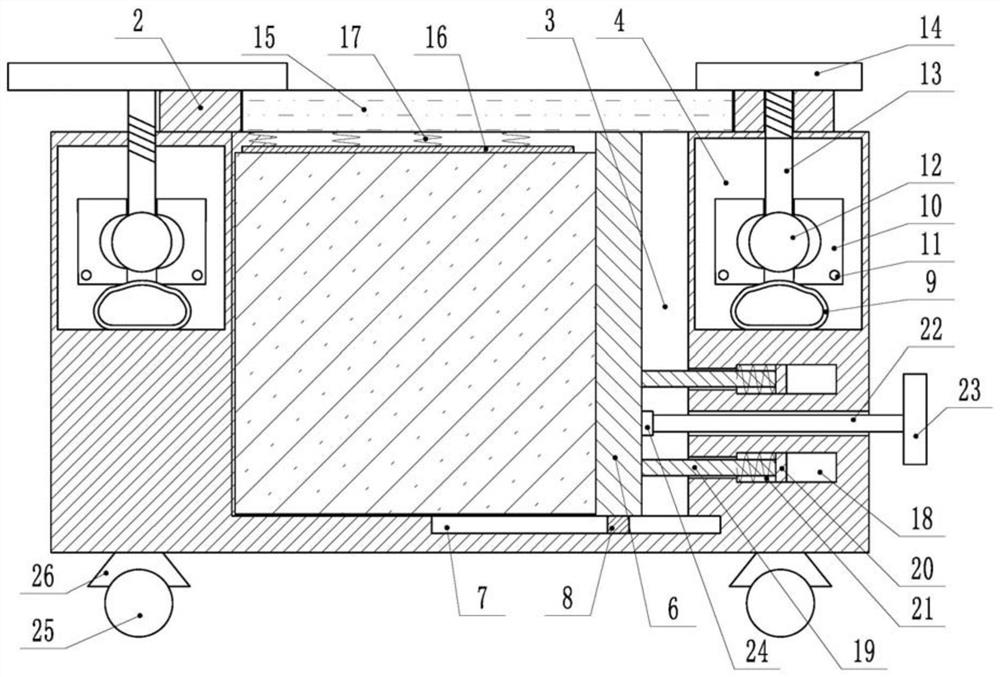

[0049] Such as image 3 As shown, the difference between the new energy vehicle battery pack transfer protection device and the first embodiment is that a secondary compression unit is also provided on the storage box 1, and the structure of the secondary compression unit is the same as that of the main compression unit, that is, the secondary compression unit The clamping unit also includes an elastic plate 9 with elastic deformation, two clamping blocks 10 and a pusher for pushing the clamping blocks 10 together.

[0050] The auxiliary pressing unit and the main pressing unit are respectively located on both sides of the placement box 1. In this embodiment, the auxiliary pressing unit is located on the left side of the placement box 1, and the pressing plate 14 of the auxiliary pressing unit can be offset against the slide plate 15 and the cover plate 2 , that is, the right side of the pressing plate 14 of the auxiliary pressing unit extends to just above the left part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com