A three-dimensional curved surface coating transfer method

A technology of covering transfer printing and curved surface, applied in the field of three-dimensional curved surface covering transfer printing, can solve the problems of high pressure of activator, damage of covering mold, uneven spraying of activator, etc., so as to improve work efficiency and avoid uneven spraying. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

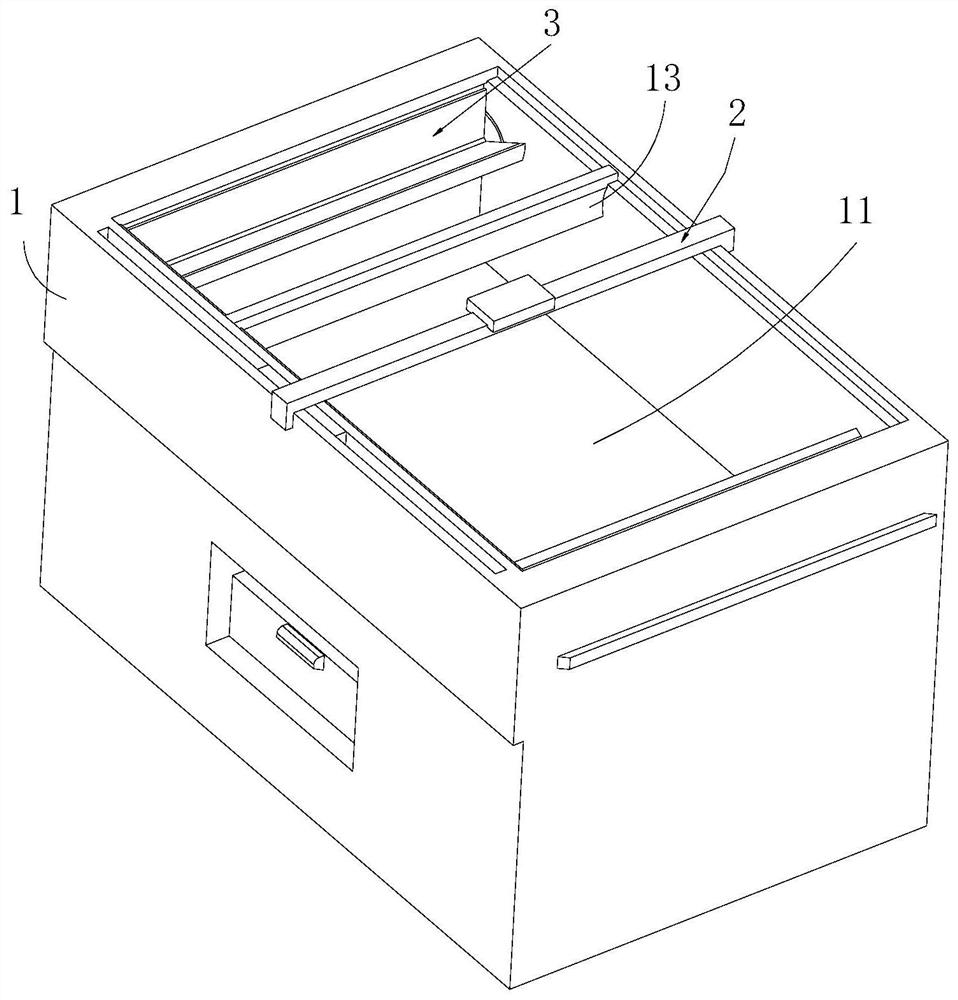

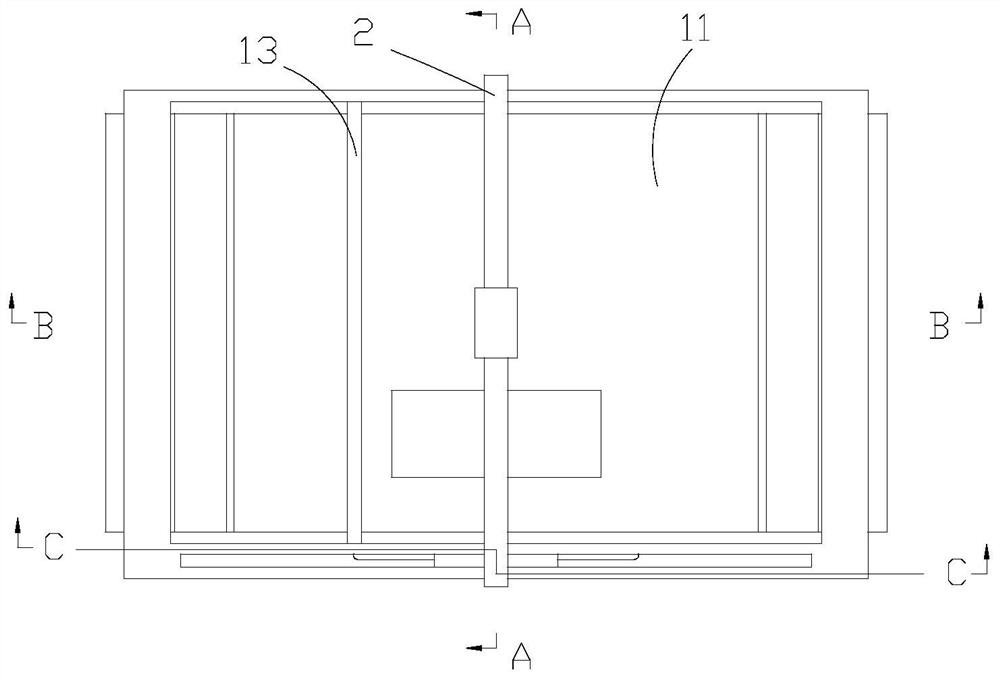

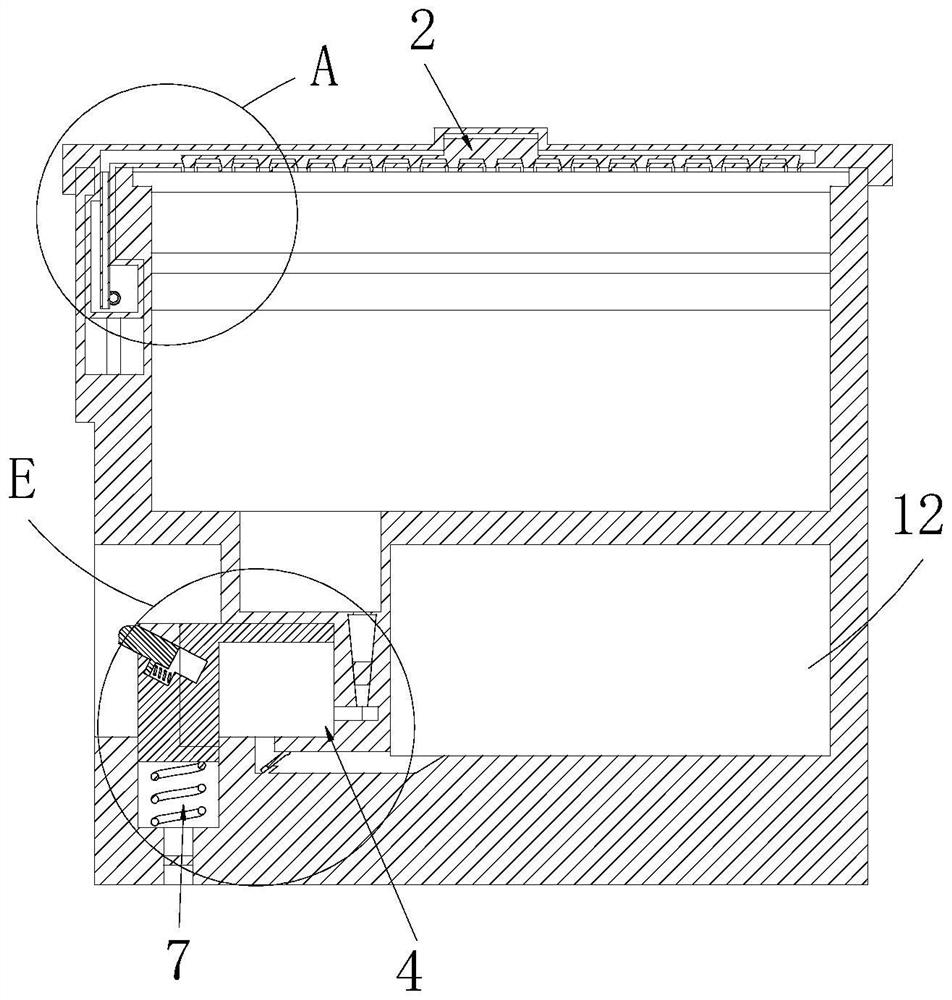

[0022] A three-dimensional curved surface coating transfer method, comprising the following steps: (1) transfer film: pre-print the desired pattern with a water-soluble film, provided by the supplier of the coating film; (2) film release: put the coating film Cut it into the required specifications of the workpiece and place it on the water surface, drain the air between the water and the film to make it completely flat on the water surface; (3) Activation: Spray the activator on the film through the activation equipment to activate the pattern on the film. Ink state; (4) Transfer printing: use water pressure to transfer the pattern activated into the ink state on the printed workpiece; (5) Washing: rinse the residual film after transfer with a washing line; (6) Baking Drying: Dry the printed workpiece in an oven; (7) Spray topcoat; spray the dried workpiece with a transparent protective layer [varnish] to protect the surface, and dry it again.

[0023] Such as Figure 1-10 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com