A paint spraying device for intelligent machinery manufacturing and processing

An intelligent machine and box technology, applied in the field of mechanical processing, can solve the problems of wasting energy, automatic control, etc., and achieve the effect of improving cleaning power and reducing work burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

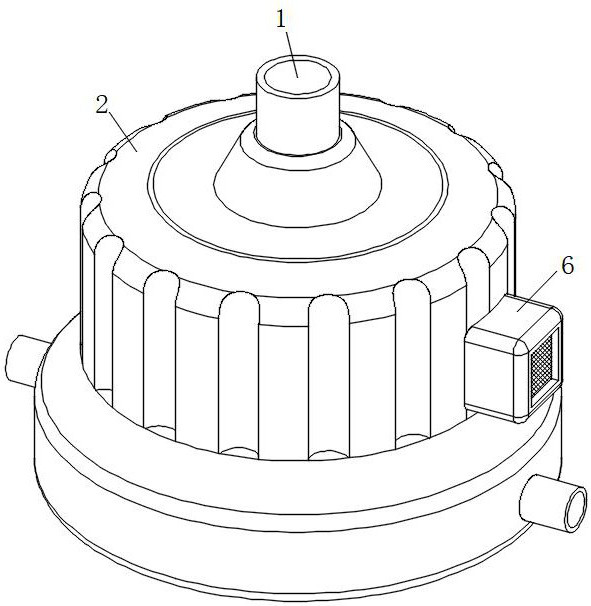

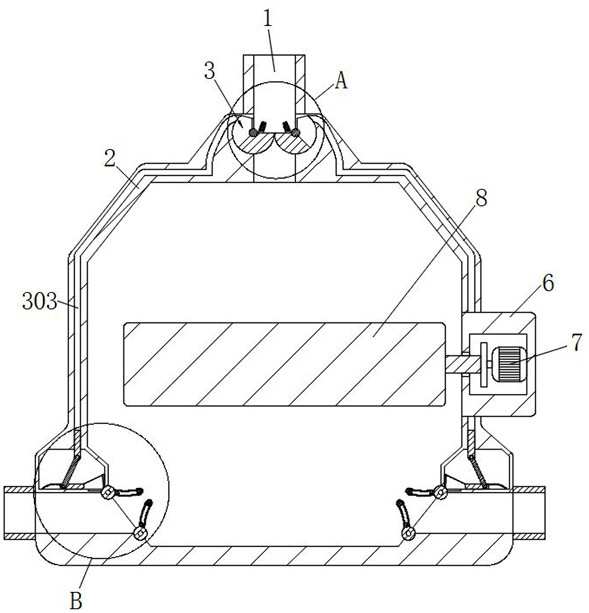

[0025] see Figure 1-6 , the present invention provides a technical solution: a paint spraying device for intelligent machinery manufacturing and processing, including a box body 2, an inlet pipe 1 is fixedly connected to the top of the box body 2, and an outer frame 6 is fixedly connected to one side of the box body 2, and the outer frame 6 One side of the inner wall is fixedly connected with a motor 7, and one end of the motor 7 is fixedly connected with a rotating rod. One end of the rotating rod runs through the right side of the box body 2 and is connected to the right side of the inner wall of the box body 2 through a bearing for rotation. The outer wall of the rotating rod is fixedly connected with a part 8. There is an air outlet duct inside the body 2, and air outlet pipes are fixedly connected to both sides of the box body 2, and the inside of the box body 2 is provided with a paint-spraying opening and closing air extraction mechanism 3;

[0026] Spray paint opening...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap