Method for prolonging shelf life and increasing adhesion degree of steamed stuffed bun stuffing

A technology of shelf life and adhesion, which is used in food ingredients as viscosity modifiers, food preservation, food homogenization, etc. , The effect of inhibiting corruption and deterioration, and reducing moisture loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: A method for prolonging the shelf life and increasing the degree of adhesion of minced meat stuffing.

[0036] (1) prepare quinoa protein solution and water-soluble chitosan solution;

[0037] (2) Preparation of quinoa protein / water-soluble chitosan composite nanosystem;

[0038] (3) preparing quinoa protein-water-soluble chitosan-stabilized eugenol Pickering emulsion;

[0039] (4) Add the Pickering emulsion prepared in step (3) to the minced meat bun filling, and mix well; (5) Add xanthan gum and hydroxyl Propyl phosphate distarch, fully mixed to obtain meat minced steamed stuffed bun stuffing with extended shelf life and increased cohesion.

[0040] Step (1) comprises: dissolving quinoa protein in deionized water and adjusting the pH value of the solution to 11 to obtain a 2% quinoa protein solution; adding water-soluble chitosan to deionized water to form a concentration of 0.75% chitosan solution; the above solutions were stirred at room temperature...

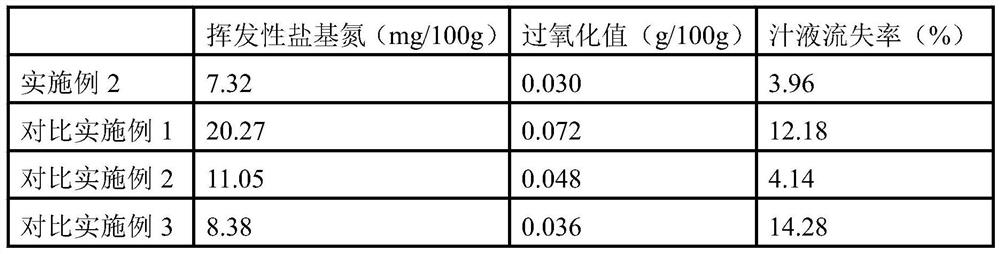

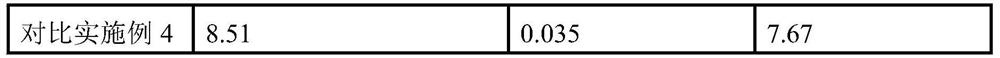

Embodiment 2

[0045] Embodiment 2: A method for prolonging the shelf life and increasing the degree of adhesion of three ding fillings.

[0046] (1) prepare quinoa protein solution and water-soluble chitosan solution;

[0047] (2) Preparation of quinoa protein / water-soluble chitosan composite nanosystem;

[0048] (3) preparing quinoa protein-water-soluble chitosan-stabilized eugenol Pickering emulsion;

[0049] (4) Add the Pickering emulsion prepared in step (3) to the stuffing of Sanding steamed stuffed bun, and mix well;

[0050] (5) Add xanthan gum and hydroxypropyl phosphate distarch to the steamed stuffed bun stuffing prepared in step (4), and mix thoroughly to obtain the three-ding steamed stuffed stuffed bun stuffing with extended shelf life and increased adhesion.

[0051] Step (1) comprises: dissolving quinoa protein in deionized water and adjusting the pH value of the solution to 11 to obtain a 2% quinoa protein solution; adding water-soluble chitosan to deionized water to form ...

Embodiment 3

[0056] Embodiment 3: A method for prolonging shelf life and increasing cohesiveness of vegetable stuffing.

[0057] (1) prepare quinoa protein solution and water-soluble chitosan solution;

[0058] (2) Preparation of quinoa protein / water-soluble chitosan composite nanosystem;

[0059] (3) preparing quinoa protein-water-soluble chitosan-stabilized eugenol Pickering emulsion;

[0060] (4) Add the Pickering emulsion prepared in step (3) to the stuffing of steamed stuffed bun with vegetables, and mix well;

[0061] (5) Add xanthan gum and hydroxypropyl phosphate distarch to the steamed stuffed bun prepared in step (4), and mix thoroughly to obtain the vegetable steamed stuffed stuffing with extended shelf life and increased adhesion.

[0062] Step (1) comprises: dissolving quinoa protein in deionized water and adjusting the pH value of the solution to 11 to obtain a 2% quinoa protein solution; adding water-soluble chitosan to deionized water to form a concentration of 0.5% chit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com