Hydrogen station and operating method for hydrogen station

An operation method and technology for a hydrogen refueling station, applied in the field of hydrogen refueling stations, can solve the problems of management and maintenance costs, large replacement costs, etc., and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

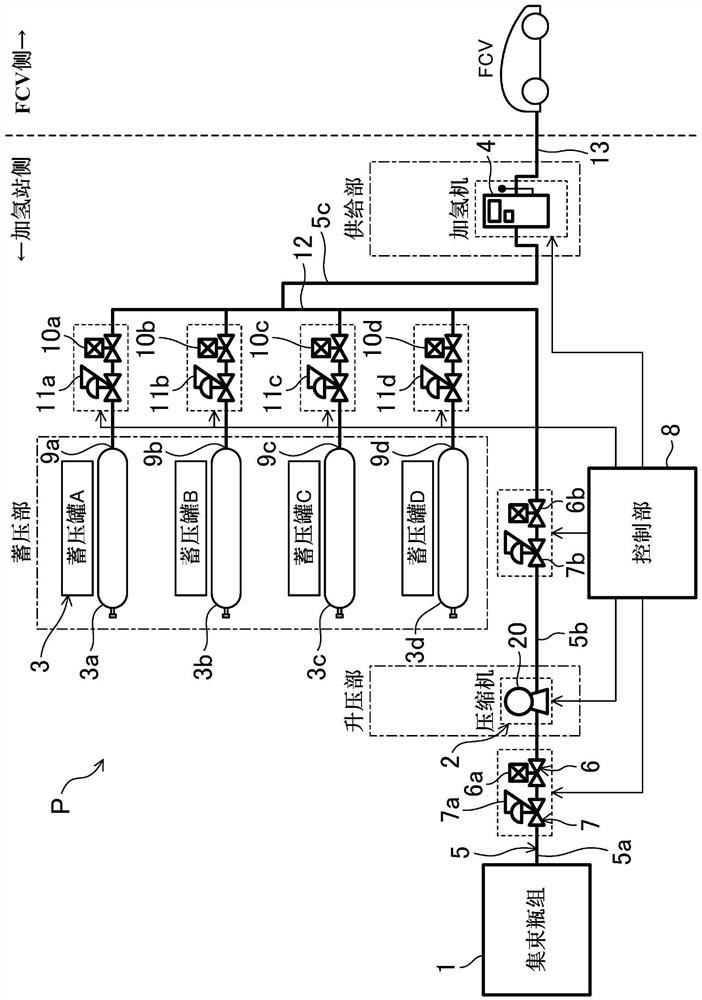

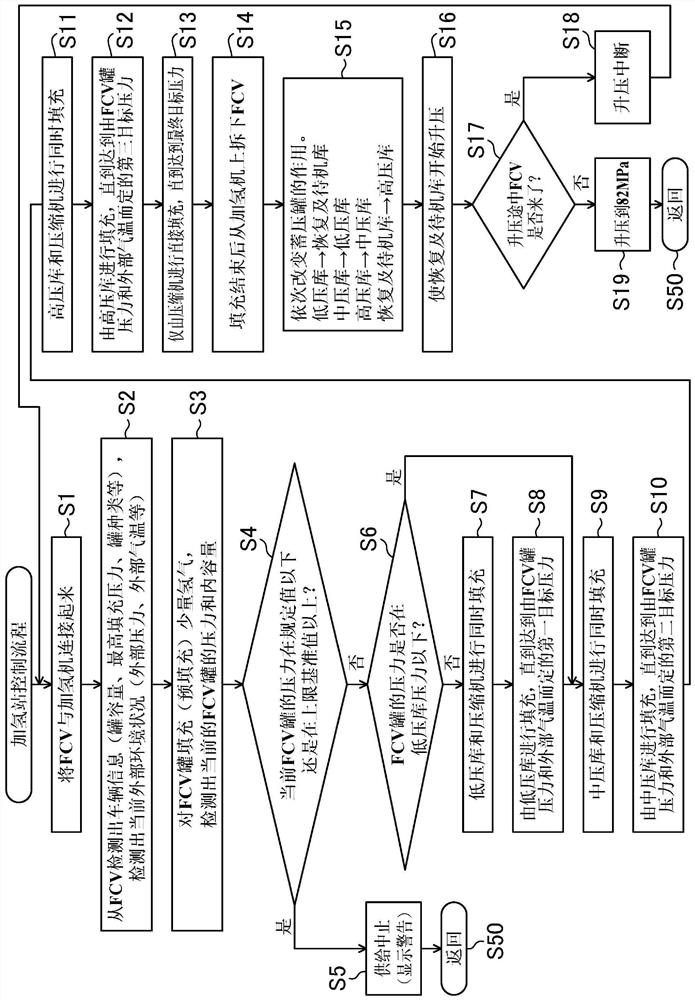

[0060] First, use figure 1 The overall configuration of the hydrogen refueling station according to the first embodiment will be described.

[0061] Such as figure 1 As shown in the system configuration diagram, the hydrogen refueling station P in this embodiment includes a cluster bottle group 1, a compressor 2, a plurality of pressure accumulator tanks 3, and a hydrogenation machine (dispenser) 4, and the cluster bottle group 1 holds a large amount of hydrogen inside. In the storage part, the compressor 2 is a pressure boosting part for boosting the hydrogen gas taken out from the cluster bottle group 1, the plurality of pressure accumulator tanks 3 is a pressure storage part for accumulating the pressure of the boosted hydrogen gas, and the hydrogenation machine 4 is a The hydrogen gas accumulated in the accumulator tank 3 is supplied to a supply unit of a fuel cell vehicle (so-called FCV (Fuel Cell Vehicle)) that is to be charged.

[0062] Furthermore, the above-mentione...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com