Large-span suspension cable pipeline bridge finished bridge wind cable line shape calculation method based on pitch line method

A calculation method and a large-span technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of not being in the same plane, the gap between the wind cable line shape and the parabola, and the inability to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] In order to make the objects, technical solutions and advantages of the present invention, the present invention will be described in detail below with reference to the accompanying drawings and examples. It will be appreciated that the specific embodiments described herein are intended to explain the invention and is not intended to limit the invention.

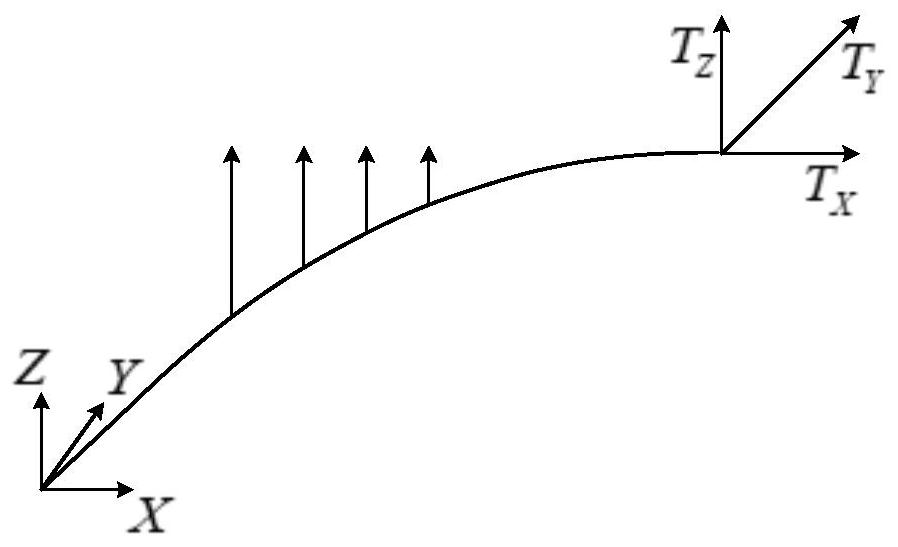

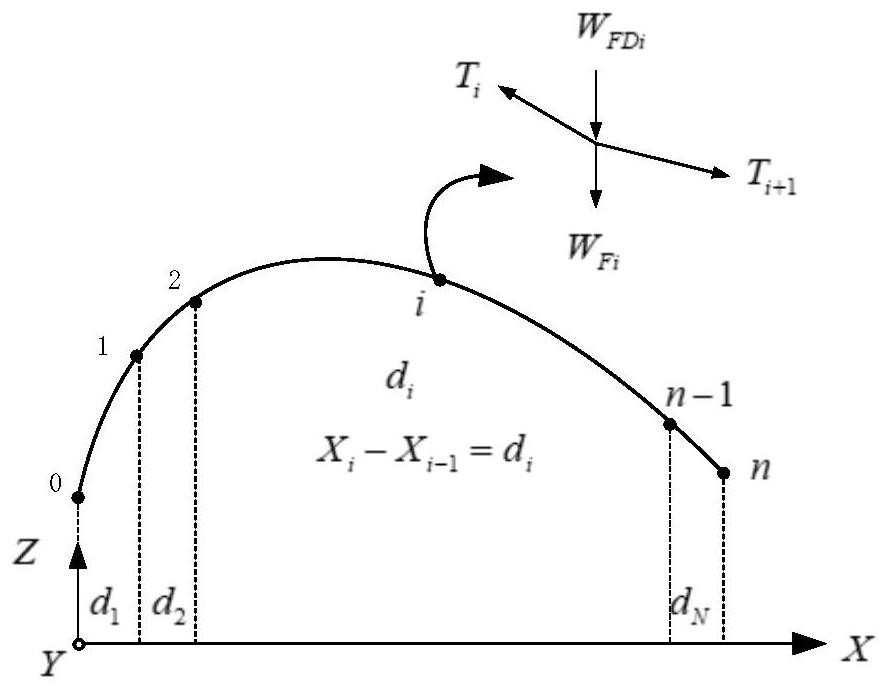

[0063] The present invention is shaped space Cable Cable Cable System Suspension air assume as follows:

[0064] (1) cable and wind the wind over the flexible cable is a small cable strain, which material satisfies Hooke's law, and the Poisson effect is ignored.

[0065] (2) to wind the cable bridge state inclined along only a transverse direction, ignoring construction cable bridge with stroke tilt error.

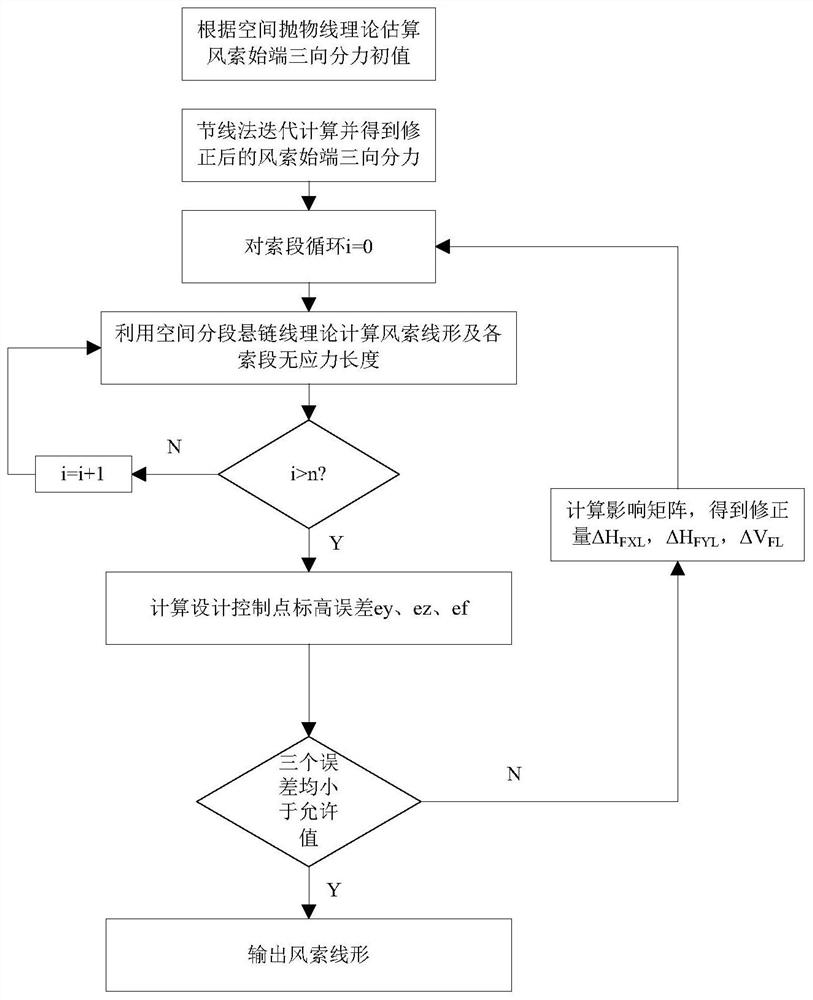

[0066] One kind of Long Span Bridges wind pipeline suspension bridge cable line section based on linear calculation method, comprising the steps of:

[0067] Step 1 The initial value of the spatial component H parabol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com