A test tool and test method for the bending mechanical properties of a honeycomb sandwich structure

A technology of honeycomb interlayer and testing tooling, which is applied to measuring devices, using stable tension/pressure to test the strength of materials, scientific instruments, etc., can solve the problems of difficult clamping and accurate positioning of displacement sensors, etc., to ensure self-balancing, guarantee Accuracy, the effect of avoiding stress deformation of the sample

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

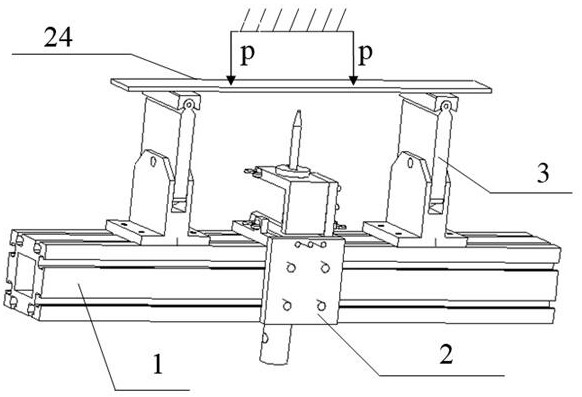

[0042] The present invention is a test tool for the bending mechanical properties of a honeycomb sandwich structure. The test tool includes: a tool base 1, a clamping device 2, a tool support 3 and a displacement sensor 18;

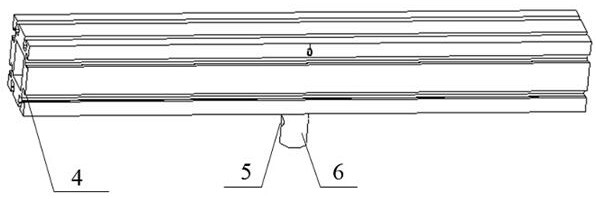

[0043] The tooling base 1 is installed on the beam of the testing machine, and the tooling base 1 is formed with a T-shaped chute 4;

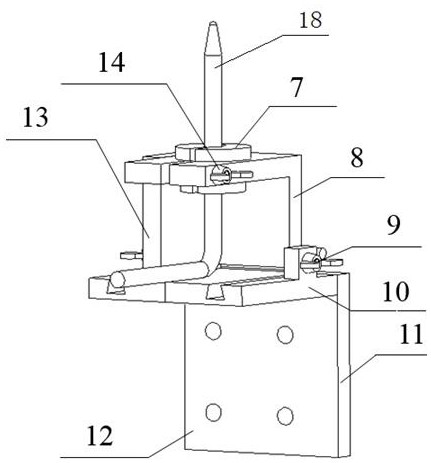

[0044] The clamping device 2 is installed in the middle position on the tooling base 1, including a clamper 7, a bracket and a slide rail base 10, the bracket is arranged on the slide rail of the slide rail base 10, and the clamper 7 is arranged on the bracket , the clamper 7 clamps the displacement sensor 18, and the bracket includes an L-shaped fixed bracket 8 and a sliding bracket 9, and the L-shaped fixed bracket 8 and the sliding bracket 9 are fixed by bolts;

[0045] The tooling support 3 is arranged on the tooling base 1 on both sides of the clamping device 2, and can slide along the T-shaped chute 4 of the tooling ...

Embodiment 2

[0054]A kind of test method of the bending mechanical performance of honeycomb sandwich structure of the present invention, the steps are:

[0055] Step 1. On the long beam bending sample of the honeycomb sandwich structure, draw a center line along the length and width directions, and the intersection of the two center lines is the center point of the sample;

[0056] Step 2. Insert the positioning cylindrical rod of the tooling base into the tray on the beam of the testing machine to realize the connection and fixation of the tooling base and the beam of the testing machine;

[0057] Step 3. Clamp displacement sensor: place the slide rail base on the tooling base, adjust the lateral position of the slide rail base to ensure that the center line of the slide rail base is aligned with the zero scale line of the tooling base, and fix it; put the displacement sensor into the clamping device;

[0058] Step 4. Install the tooling support: slide the bottom of the tooling support i...

Embodiment 3

[0066] Such as figure 1 , 2 , 3, 4 shown. A tooling device for testing the bending mechanical properties of a long beam with a honeycomb sandwich structure is composed of a tooling base 1 , a clamping device 2 , a tooling support 3 and a displacement sensor 18 .

[0067] Step 1, on the honeycomb sandwich structure long beam bending sample 24, draw a center line respectively along the length and width directions, and the intersection of the two center lines is the center point of the sample;

[0068] Step 2. Insert the positioning cylindrical rod 6 of the tooling base 1 into the tray on the beam of the testing machine, and realize the connection and fixation of the tooling base 1 and the beam of the testing machine through the positioning hole 5;

[0069] Step 3: Clamp the displacement sensor, fix the slide rail base 10 and the limit plate 11 through screw connection, place the combined device of the slide rail base 10 and the limit plate 11 on the tooling base 1, and adjust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com