A testing system and method for a support mechanism of a drilling traction robot

A technology for supporting mechanisms and testing systems, which is applied in the testing of machine/structural components, testing of mechanical components, instruments, etc. It can solve the problem of long experimental preparation period, high cost, and inability to support the optimal design of mechanism structure and provide experimental data for reference. and other problems, to achieve the effect of reducing the experimental preparation period and the experimental cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

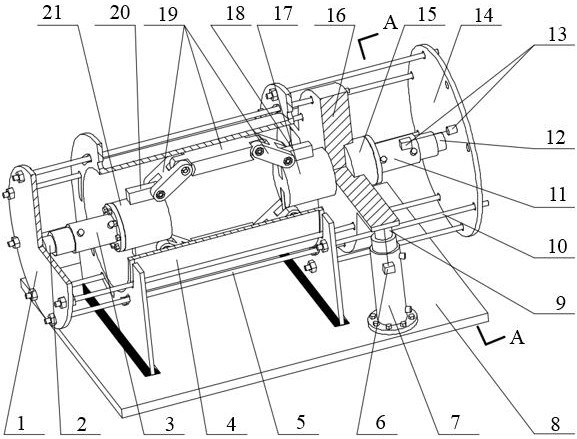

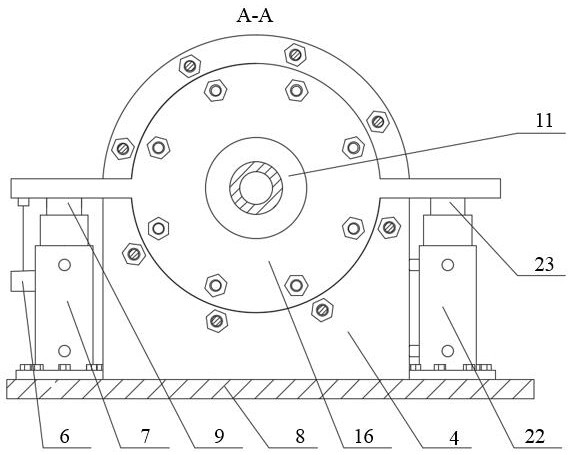

[0034] The present invention will be further described below in conjunction with the accompanying drawings, and the protection scope of the present invention is not limited to the following description:

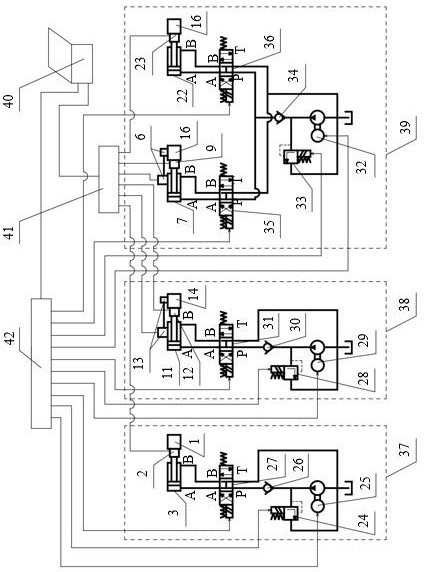

[0035] like Figures 1 to 3 As shown, a reliability testing system for a support mechanism of a drilling traction robot includes a support simulation system (37), a telescopic simulation system (38), a torsion simulation system (39), a data acquisition system (41), and a control execution system (42). ), computer (40); said: the pressure pump A (25) is connected in parallel with the electromagnetic relief valve A (24), and is connected in series with the check valve A (26), and the check valve A (26) is connected with the electromagnetic reversing valve. The P port of A(27) is connected, and the T port of the electromagnetic reversing valve A(27) is connected to the fuel tank; the pressure pump B(29) is connected in parallel with the electromagnetic relief valve B(28), and is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com