Optical lens center thickness measurement and positioning clamp

A technology for positioning fixtures and optical lenses, used in measuring devices, using optical devices, mechanical measuring devices, etc., can solve the problems of reduced measurement accuracy, easy shaking or deviation of optical lenses, and inability to achieve measurement accuracy. High, achieve repeat positioning, improve the effect of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to deepen the understanding of the present invention, the present invention will be further described in detail below with reference to the implementation cases and accompanying drawings. The present invention can be implemented in the following ways:

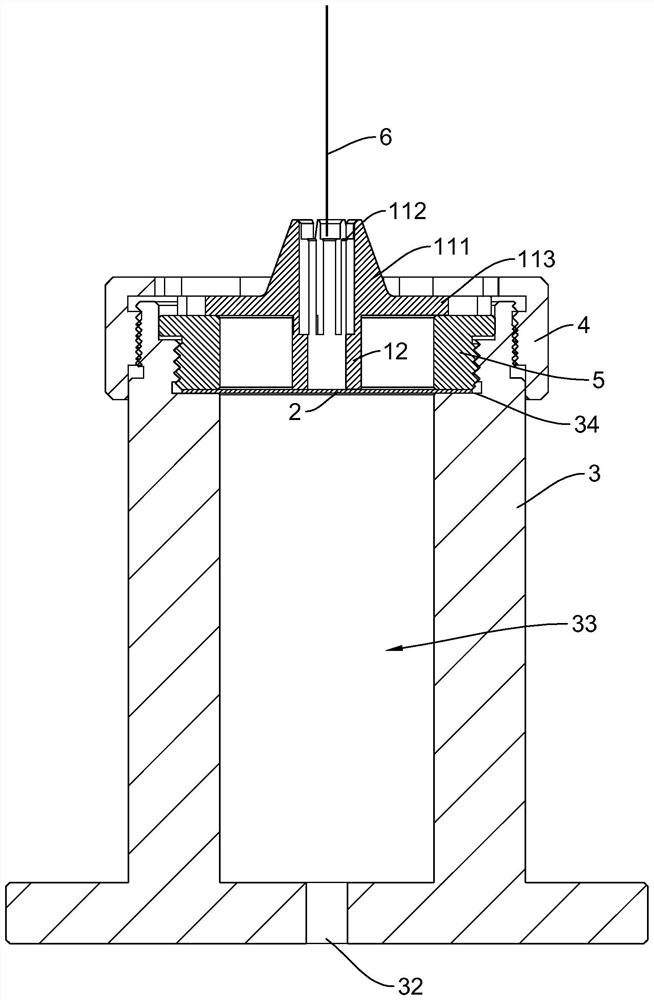

[0034] refer to Figure 1-8 , an optical lens center thickness measurement and positioning fixture, including an elastic positioning fixture 1, an elastic sheet 2 and a gas source cavity 3 arranged in sequence from top to bottom, the gas source cavity 3 is an air pressure cavity inside, and the gas source cavity 3 is Made of metal material. The top of the gas source cavity 3 is provided with an upper opening, and the elastic sheet 2 can detachably seal the upper opening; the gas source cavity 3 is also provided with an inlet for gas to enter or discharge the gas source cavity. Air exhaust hole 32 . The elastic positioning fixture 1 is provided with a petal-shaped elastic chuck 11 , and a column 12 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com