A real-time monitoring and detection system for aluminum alloy enameled wire

A detection system and real-time monitoring technology, applied in the direction of mechanical roughness/irregularity measurement, etc., can solve the problems of unusability, segmentation and marking, large current passing through, and achieve the effect of improving accuracy and suitable tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

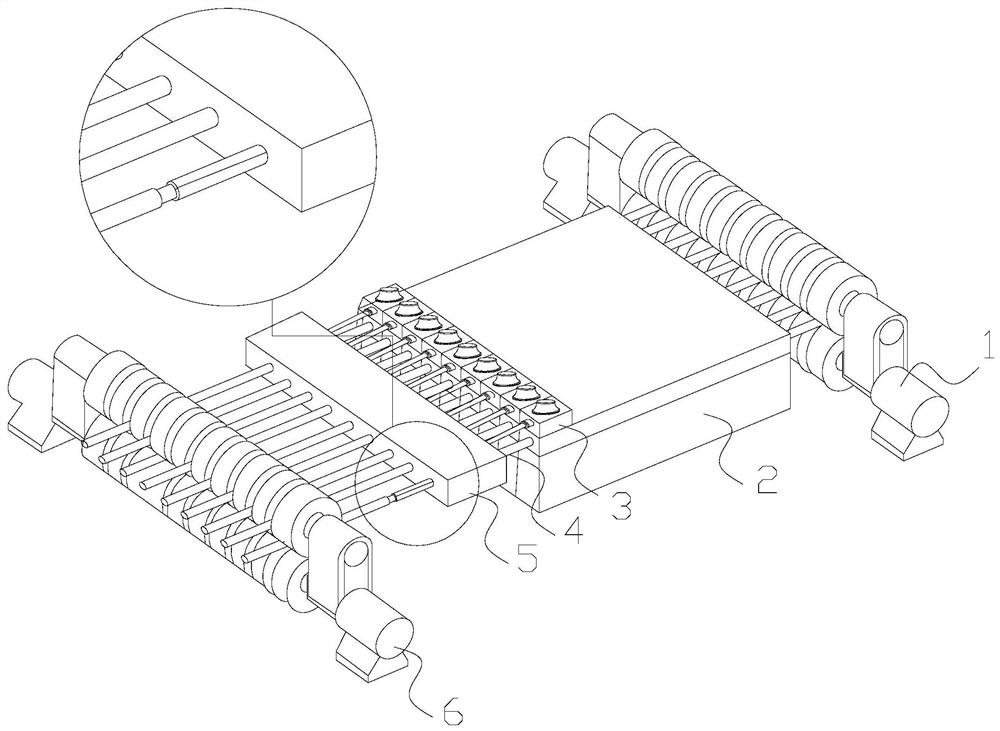

[0026] see Figure 1-Figure 5 , a real-time monitoring and detection system for aluminum alloy enameled wire. The present invention provides a real-time monitoring and detection system for aluminum alloy enameled wire. 6. An outgoing line cylinder 6 is installed between the incoming line cylinder 1 and the outgoing line cylinder 6, and a checker 3 is vertically installed on the end of the distribution board 2 away from the incoming line cylinder 1, and the checker 3 A slitting box 5 is installed between the outgoing line cylinder 6, and more than two enameled wires 4 enter from the incoming line cylinder 1, pass through the line splitter 2, check with the tester 3, or be cut by the slitting box 5, Finally, the outlet is completed through the outlet cylinder 6.

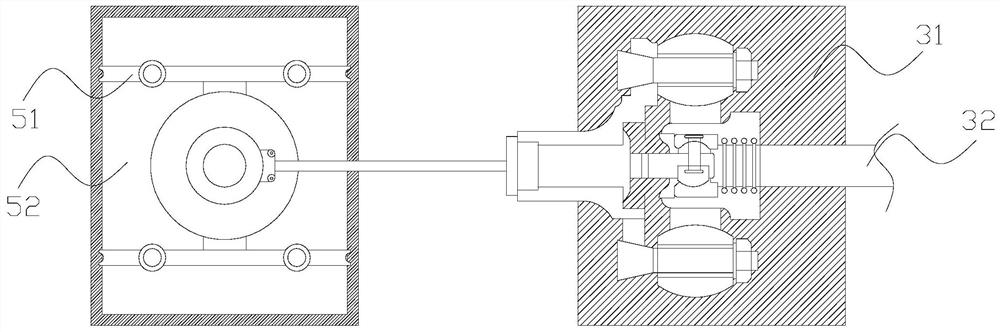

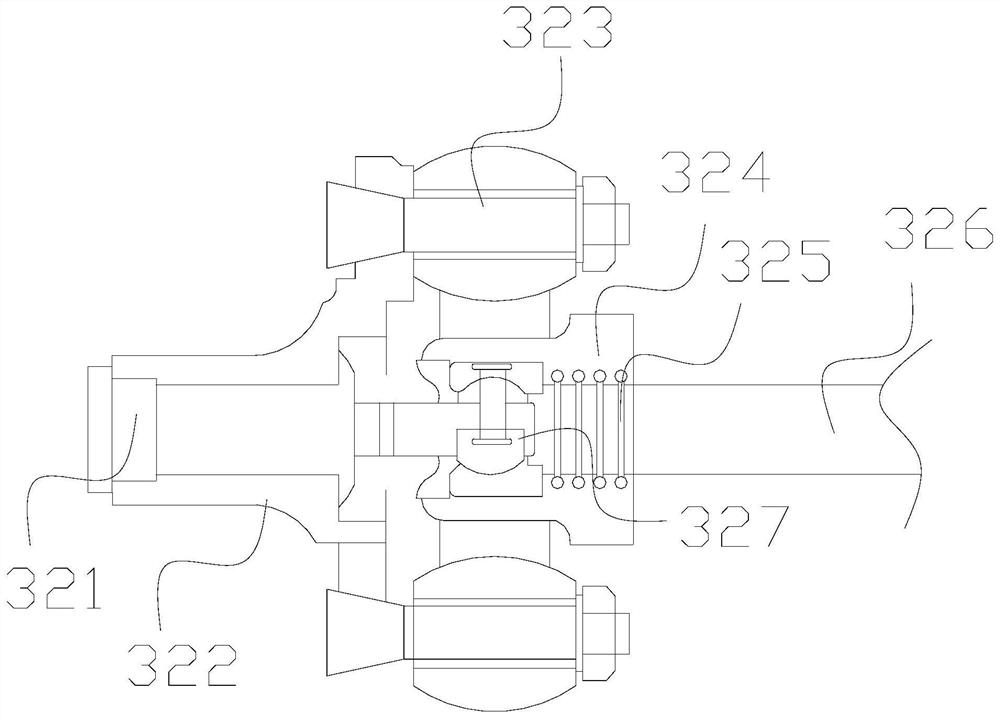

[0027] The tester 3 includes a housing 31 and a sheet-fit detection mechanism 32. A sheet-fit detection mechanism 32 is installed in the middle of the housing 31. The sheet-fit detection mechanism 32 includes a termin...

Embodiment 2

[0035] see Figure 1-Figure 5 , a real-time monitoring and detection system for aluminum alloy enameled wire. The present invention provides a real-time monitoring and detection system for aluminum alloy enameled wire. 6. An outgoing line cylinder 6 is installed between the incoming line cylinder 1 and the outgoing line cylinder 6, and a checker 3 is vertically installed on the end of the distribution board 2 away from the incoming line cylinder 1, and the checker 3 A slitting box 5 is installed between the outgoing line cylinder 6, and more than two enameled wires 4 enter from the incoming line cylinder 1, pass through the line splitter 2, check with the tester 3, or be cut by the slitting box 5, Finally, the outlet is completed through the outlet cylinder 6.

[0036] The tester 3 includes a housing 31 and a sheet-fit detection mechanism 32. A sheet-fit detection mechanism 32 is installed in the middle of the housing 31. The sheet-fit detection mechanism 32 includes a termin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap