Construction Technology of Long Spiral Cast-in-situ Pile with Vibration and Tube Follower

A technology of long spiral cast-in-place pile and construction technology, which is applied in sheet pile wall, foundation structure engineering, construction, etc., can solve the problems of limited joint diameter of pile foundation, insufficient bearing capacity of single pile, and inability to meet the requirements of bearing strength, etc. Achieve the effect of avoiding shrinking and collapsing holes, improving construction quality and increasing bearing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following is attached Figure 1-3 The application is described in further detail.

[0040] The embodiment of the present application discloses the construction process of long spiral cast-in-situ piles with vibrating follow-up pipes, including the following construction steps:

[0041] Step 1. Preparation before construction

[0042] Comprehensively evaluate the construction site, select the appropriate filling pile position according to the foundation and soil layer conditions, measure the pile position and mark it with steel bars, measure the ground elevation in the site to determine the buried depth of the pile top, and use the level to control the plane error of the pipe pile and the verticality of the pile body degree of deviation;

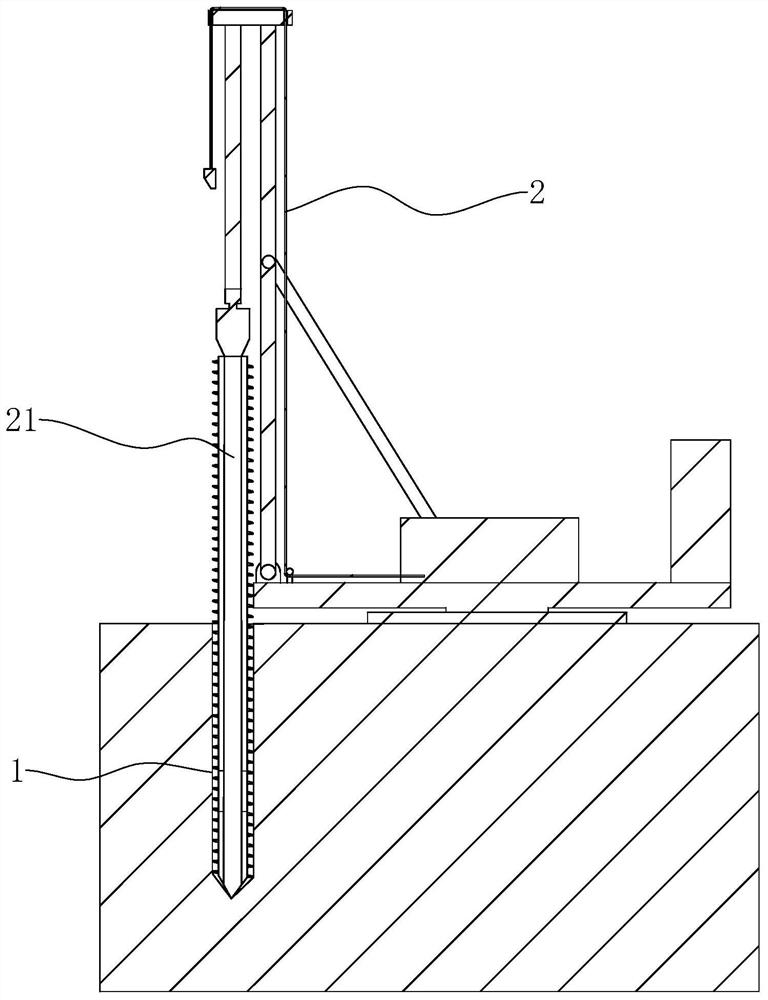

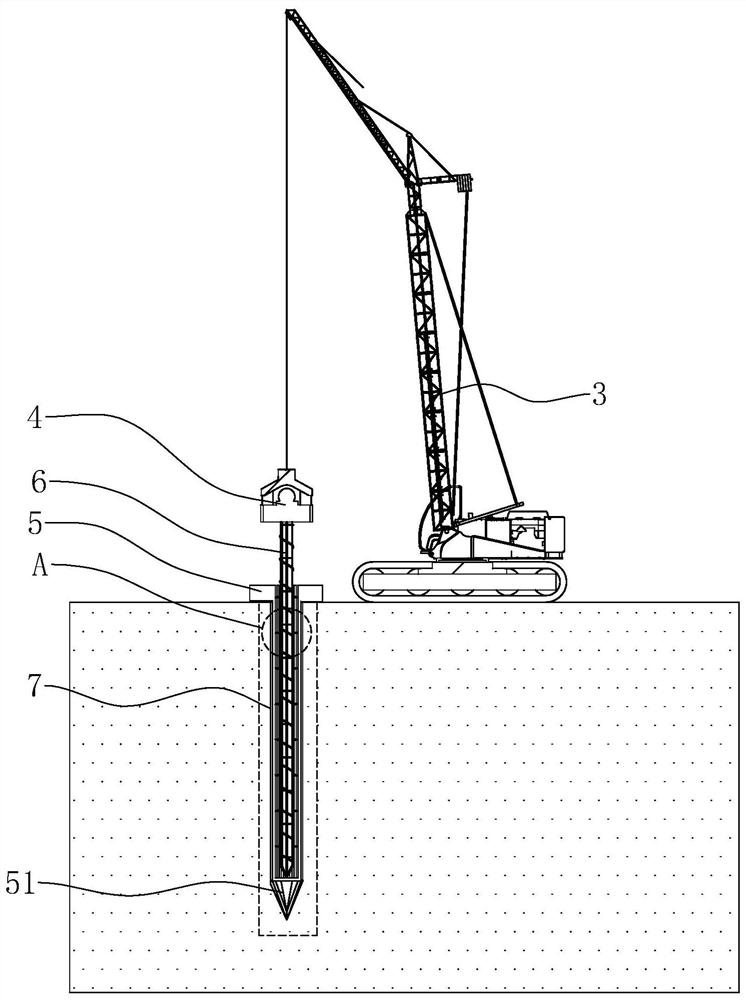

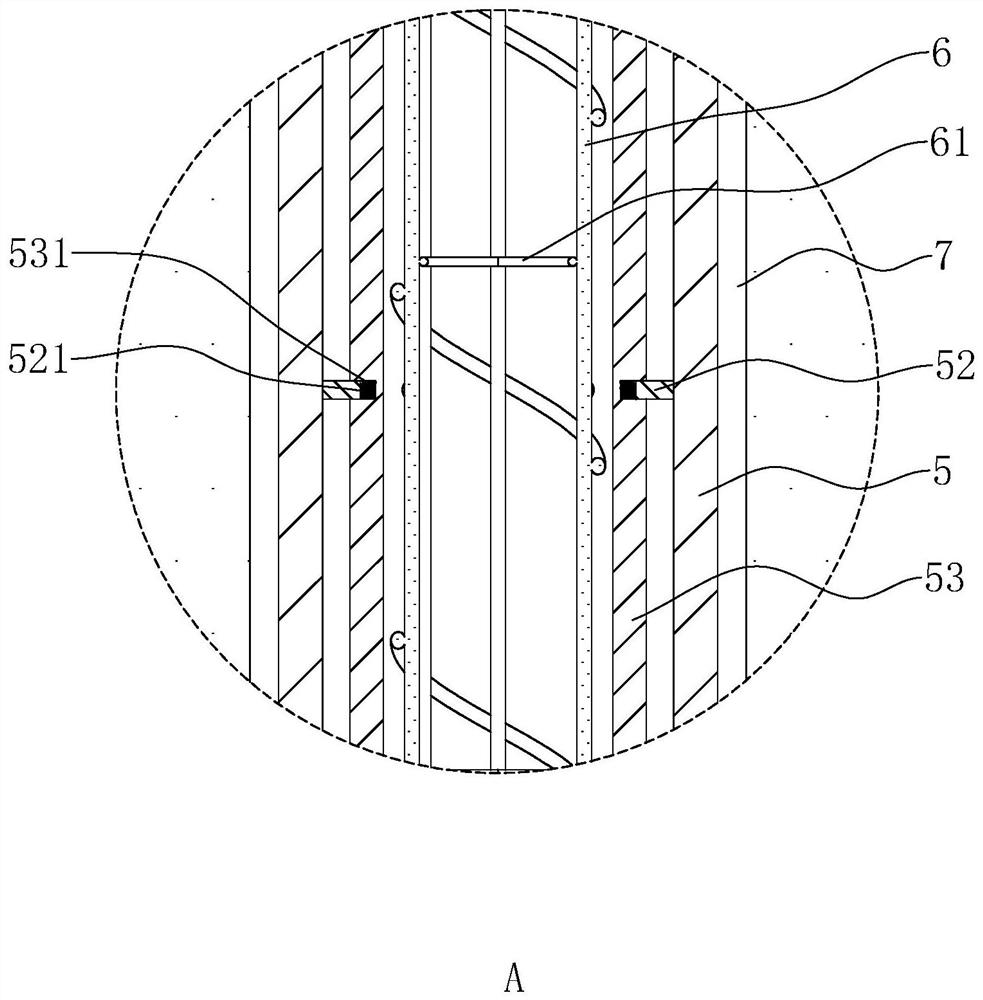

[0043] refer to figure 1 and figure 2 , select the crawler-type long helical multifunctional bored pile driver 2, crane 3, vibratory hammer 4, excavator and shovel as construction machines, wherein the long helical multifuncti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com