Processing method of steering vertical axle seat of 8×8 wheeled armored vehicle

A processing method and vertical shaft technology are applied in the field of precision machining of the steering vertical shaft seat of an 8×8 wheeled armored vehicle, which can solve the problems of welding deformation of the shaft seat hole and high rework probability of the steering vertical shaft seat, and achieve the effect of reducing the rework probability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

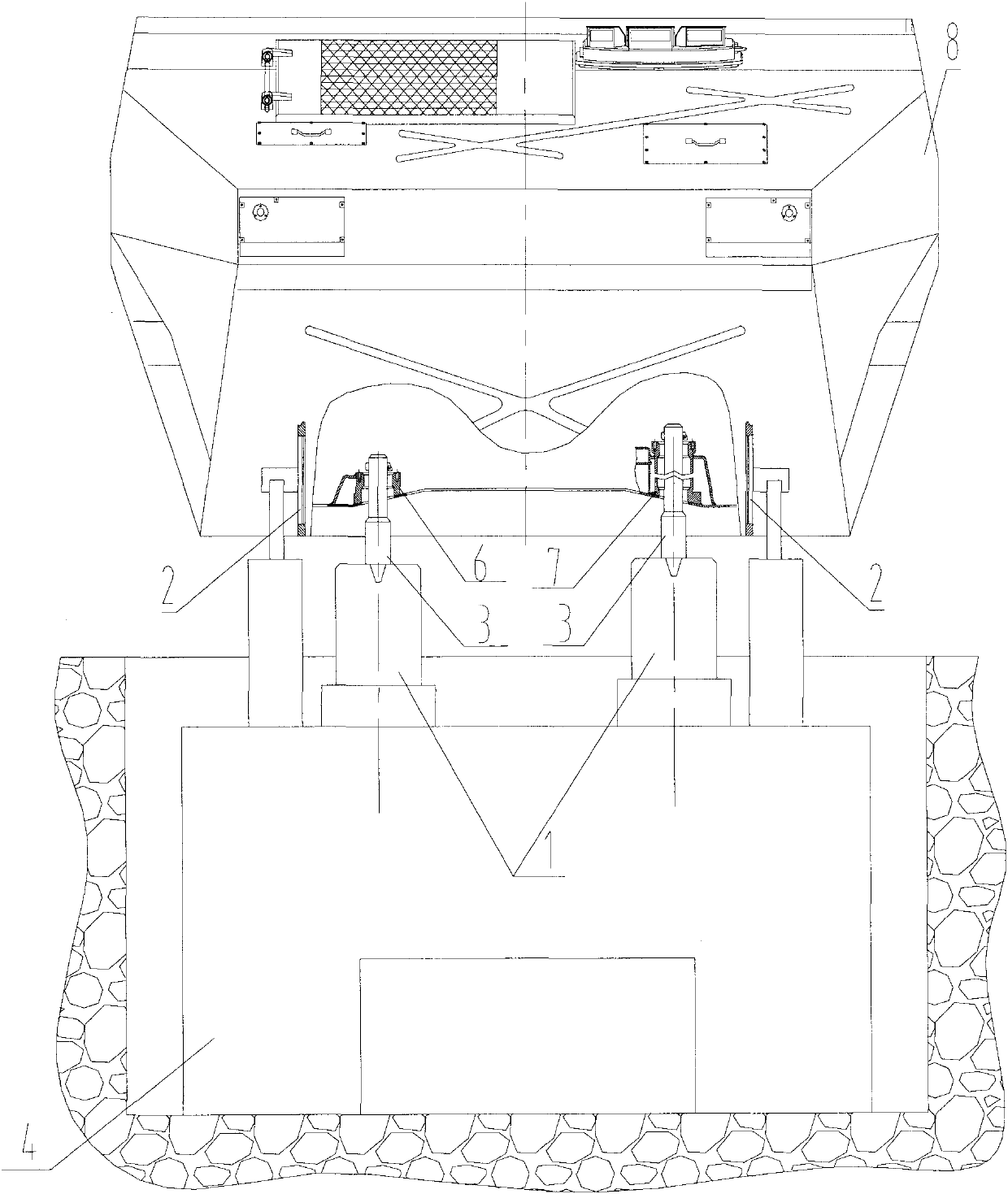

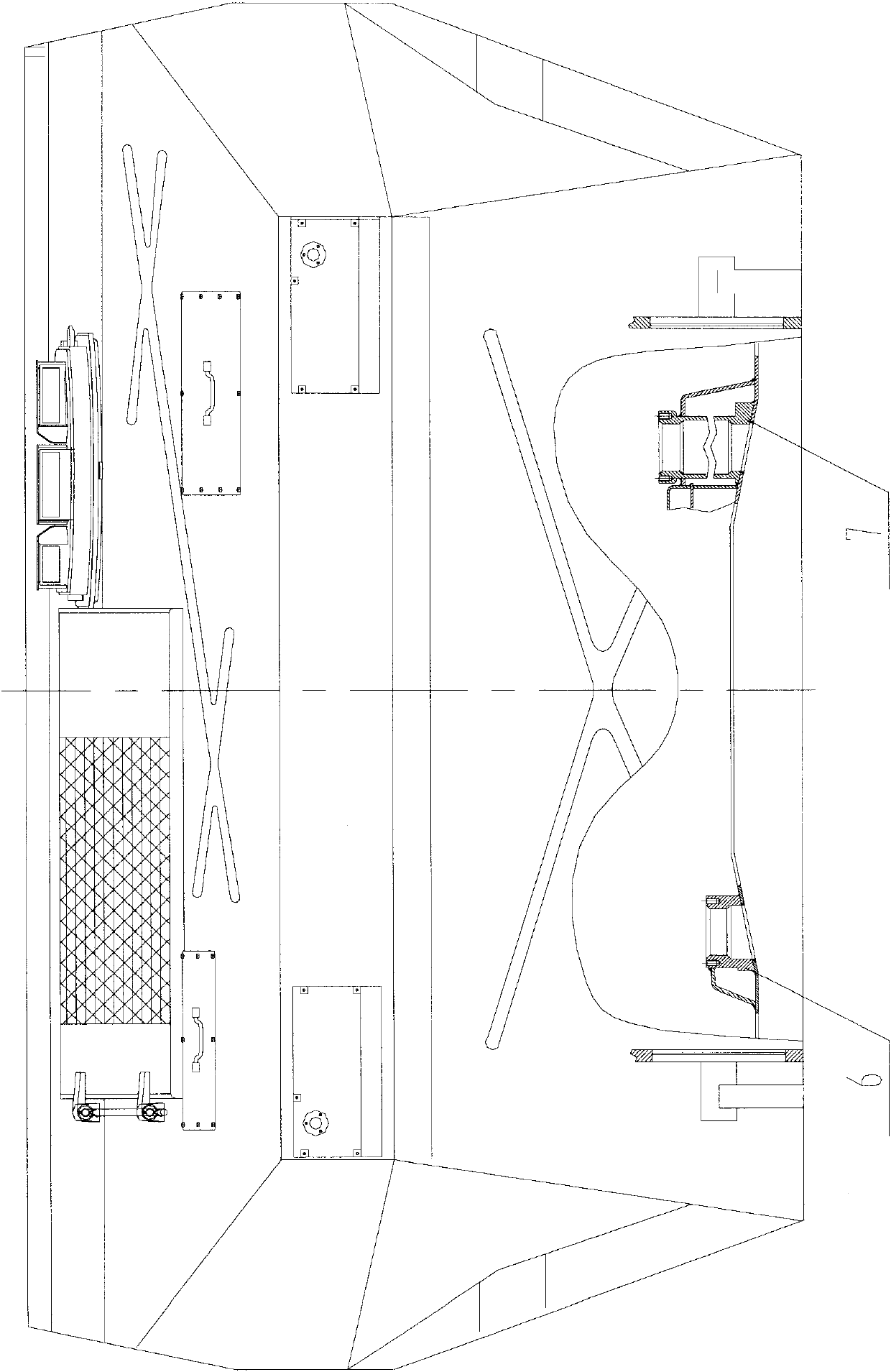

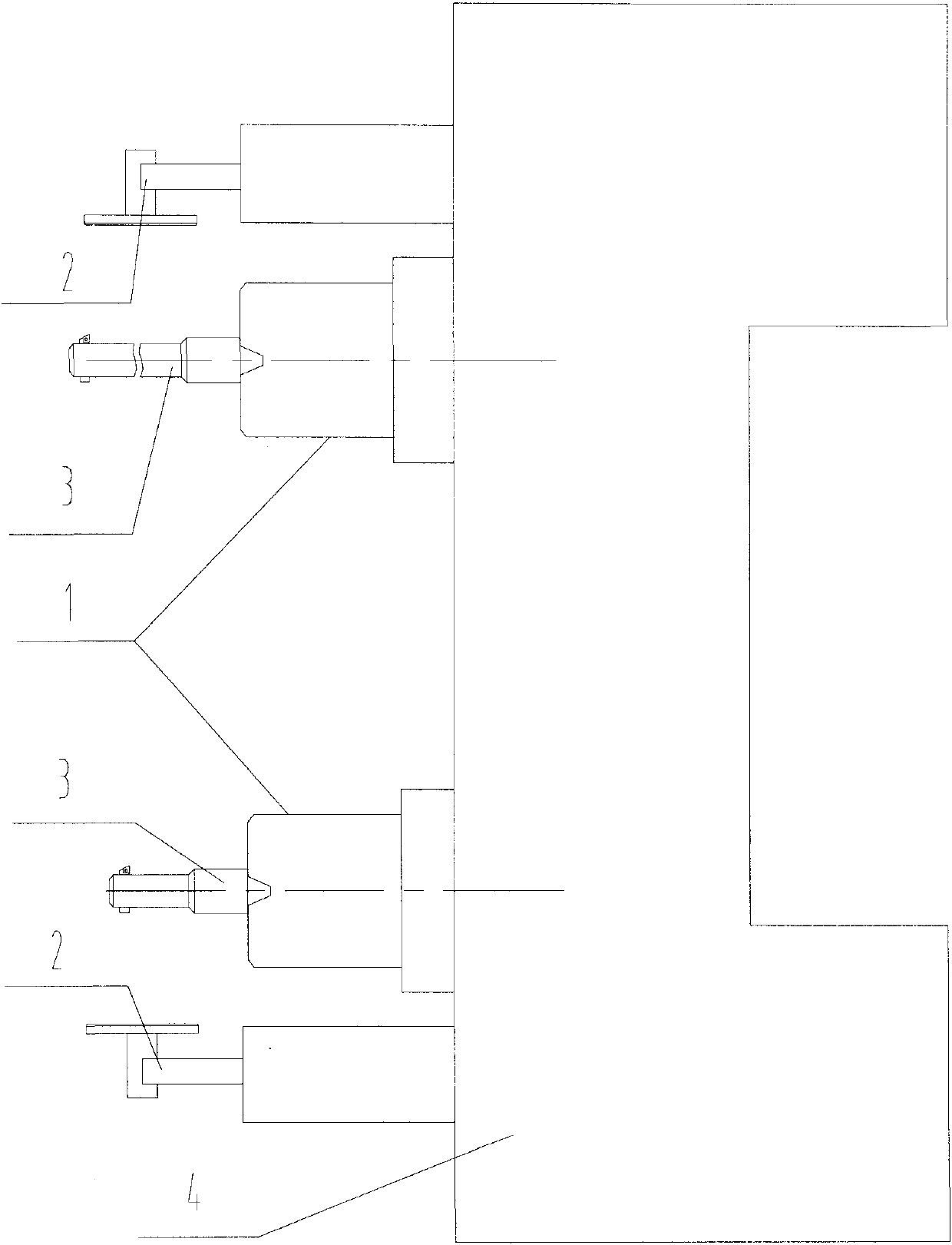

[0014] As shown in the figure, the present invention is a precision machining method for the steering shaft seat of an 8×8 wheeled armored vehicle. Body and special tool assembly, the machine tool 4 is installed under the ground plane.

[0015] The 8×8 wheeled armored vehicle 8 is provided with two vertical shaft seats, i.e. the vertical shaft seat 6 and the vertical shaft seat 7. During processing, the wheeled armored vehicle is first installed on the positioning of the special processing machine tool 4 based on the axle hole of the wheeled armored vehicle. On the clamping device 2, then adjust the boring tool 5 on the tool bar 3 to a range smaller than the aperture of the vertical shaft seat, start the power head 1, and make the cutter pass through the bottom hole of the vertical shaft seat. Adjust the boring tool 5 to the semi-finishing requirements of the hole diameter of the vertical shaft seat, start the power head 1, select the tool feed, speed and other parameters, sem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com