Preparation method of paper-based packaging material with ultraviolet shielding function

A packaging material and outer shielding technology, applied in pulp beating method, pulp beating/refining method, paper coating, etc., can solve the problems of color fading, product deterioration appearance, ugly, etc., to improve crystal growth and paper quality indicators Improve the effect of good surface stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

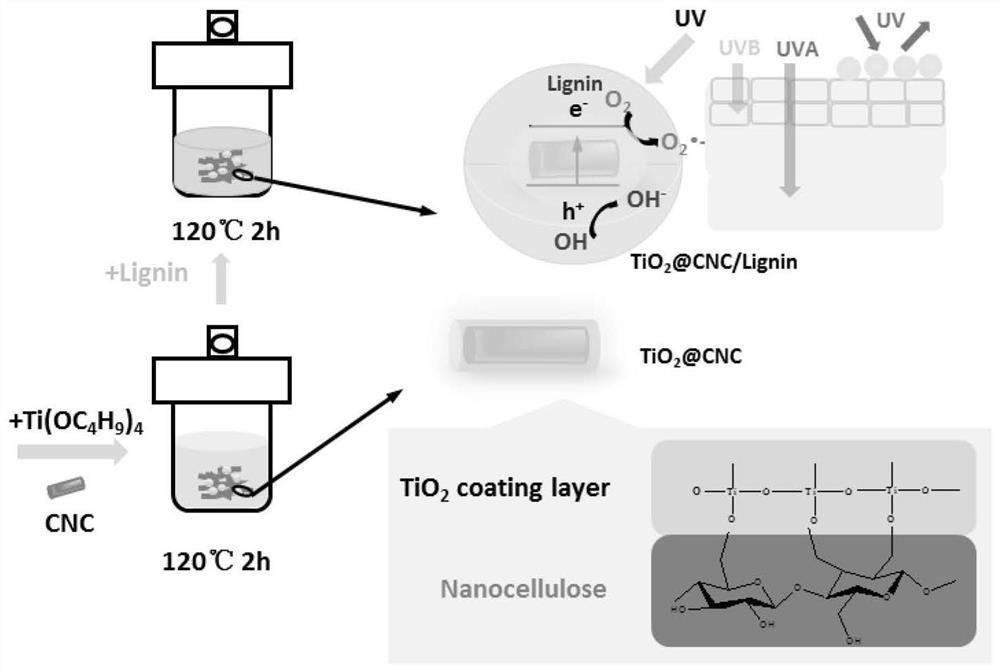

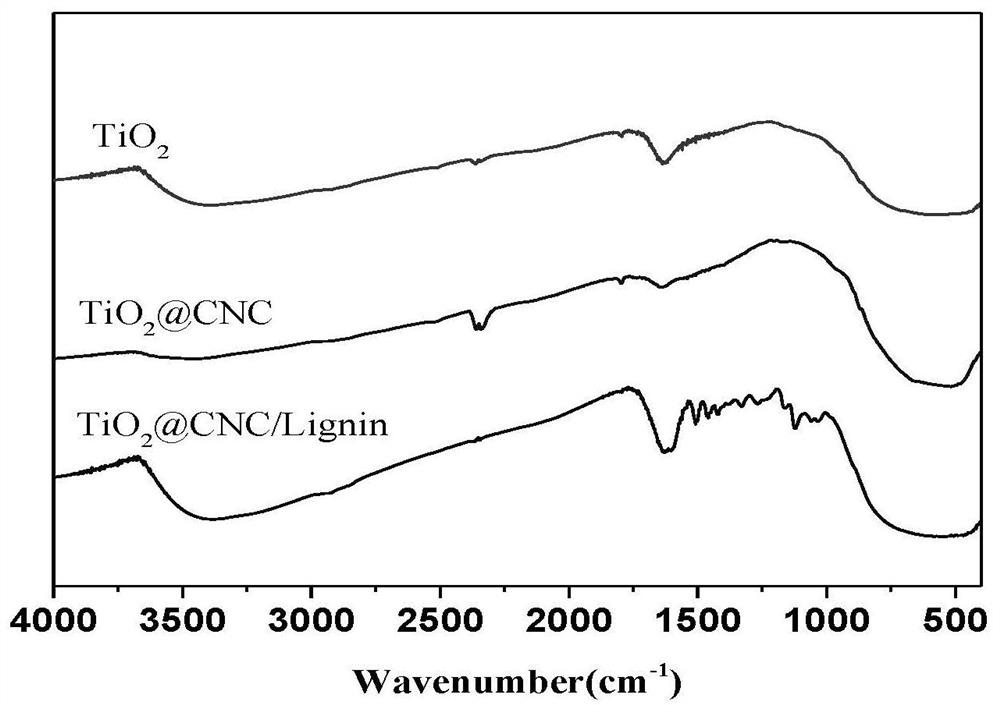

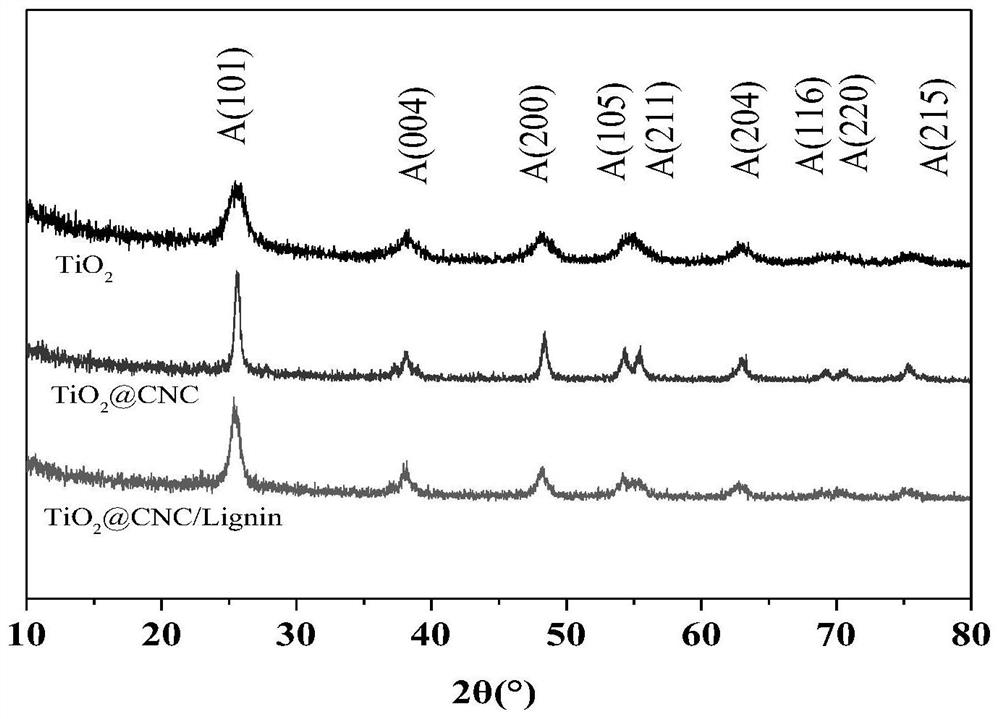

Method used

Image

Examples

Embodiment 1

[0040]Embodiment 1: The preparation method of the paper-based packaging material with ultraviolet shielding function is carried out according to the following steps: 9 parts of cellulase with an enzyme activity index of 2800U, 6 parts of pectinase with an enzyme activity index of 2400U and enzyme activity in parts by mass 5 parts of xylanase with an index of 3300U are used to prepare a compound biological enzyme agent; then 70 parts of softwood pulp boards and 30 parts of hardwood pulp boards are put into the pulper, and an appropriate amount of water is added to dissolve the pulp boards to form pulp. The water temperature is 25°C , then add the relative absolute dry mass of the pulp board in the raw material solution (i.e. the absolute dry mass of the mixed pulp board in the pulper after removing water; the ratio of the relative dry mass of the softwood pulp board and the hardwood pulp board is a conventional parameter, It can be multiplied by the weight of the softwood pulp b...

Embodiment 2

[0041] Embodiment 2: The preparation method of the paper-based packaging material with ultraviolet shielding function is carried out according to the following steps: 8 parts of cellulase with an enzyme activity index of 2500U, 5 parts of pectinase with an enzyme activity index of 2500U and enzyme activity in parts by mass 5 parts of xylanase with an index of 3500U are used to prepare a compound biological enzyme agent; then 73 parts of softwood pulp boards and 27 parts of hardwood pulp boards are put into the pulper, and an appropriate amount of water is added to dissolve the pulp boards to form pulp. The water temperature is 25 °C , and then add a compound biological enzyme agent of 600ppm relative to the dry pulp board weight in the raw material solution to decompose. The decompression time is 15min. The pulp after decompression is sent to the refiner for beating. The total power of the defibrination is 270kw / h. It is 3.5%, beating until the degree of beating is 38 ° SR, and...

Embodiment 3

[0042] Embodiment 3: on the basis of embodiment 2, after coating, the base paper after coating is put into air pressure treatment tank, controls air pressure according to standing time, relational formula is:

[0043] Where: P is air pressure, t is time.

[0044] For example, in Example 2, in the process of standing for 4 seconds after coating, the air pressure rises from 1 MPa to 2 MPa in the process of 0-2 seconds, and then in the process of 2-4 seconds, the air pressure drops from 2 MPa to 1MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com