In-hole velvet lifting process screen cloth as well as manufacturing method and application thereof

A production method and process technology, which is applied in the field of velvet fabric in the hole, can solve the problems of poor plush effect, abnormal hand feeling, flat plush, etc., and achieve the effect of soft hand feeling, good line retention and comfortable hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

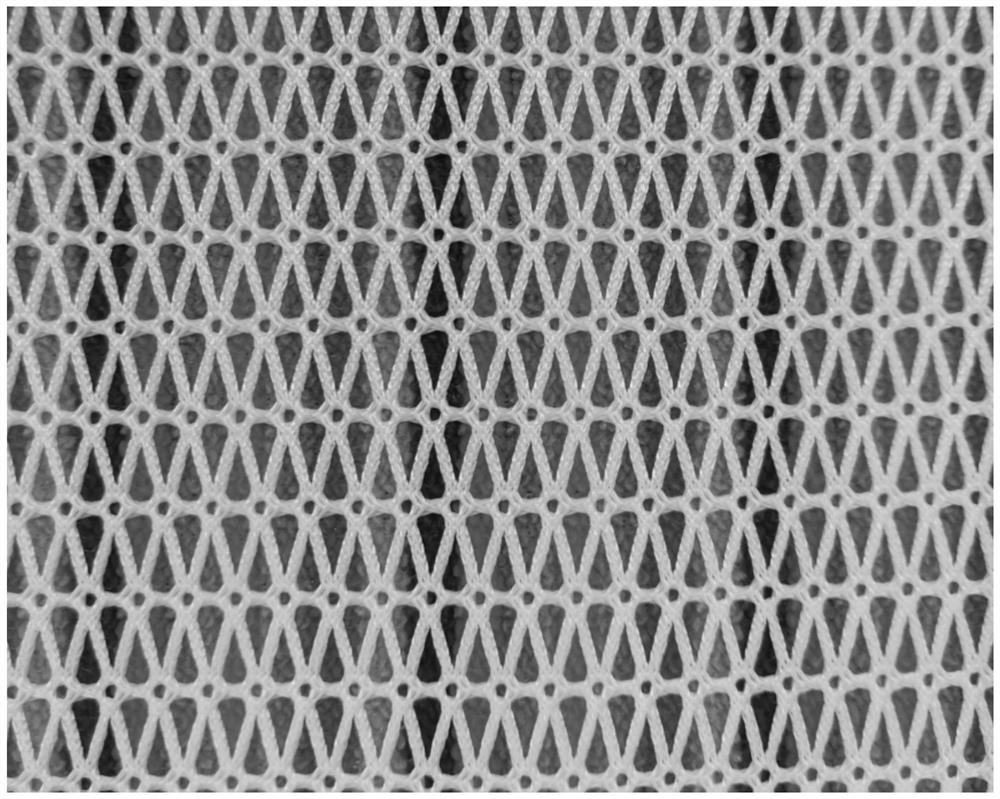

Embodiment 1

[0054] The manufacturing method of the fleece fabric mesh cloth in the warp-knitted geometric mesh hole, the face mesh layer 1:

[0055] GB1: Warping P-FDY150D / 96F semi-gloss yarn has 6 pan heads and 238 yarns in each pan head. The threading of GB1 yarn on the machine is one thread and one empty. The warp let-off amount of the gear is 650mm / lac GB1 running weft insertion weave 0-0 / 2-2 / / , GB1 polyester yarn content accounts for about 2.761%.

[0056] GB2: Warping P-FDYP-FDY300D / 96F semi-gloss yarn with 6 pan heads and 238 yarns in each pan head. GB2 yarn is threaded on the machine in the way of 2 threads and 2 holes, and the warp let-off amount of the gear is 2000mm / Lak, GB2 change warp and satin weave 1-0 / (2-3 / 3-2)*2 / 4-5 / (3-2 / 2-3)*2 / / , GB2 polyester yarn content accounts for 16.989% about.

[0057] GB3: Warping P-FDYP-FDY300D / 96F semi-gloss yarn has 6 pan heads and 238 yarns in each pan head. The threading of GB3 yarn on the machine is 2 threads and 2 empty, and the warp le...

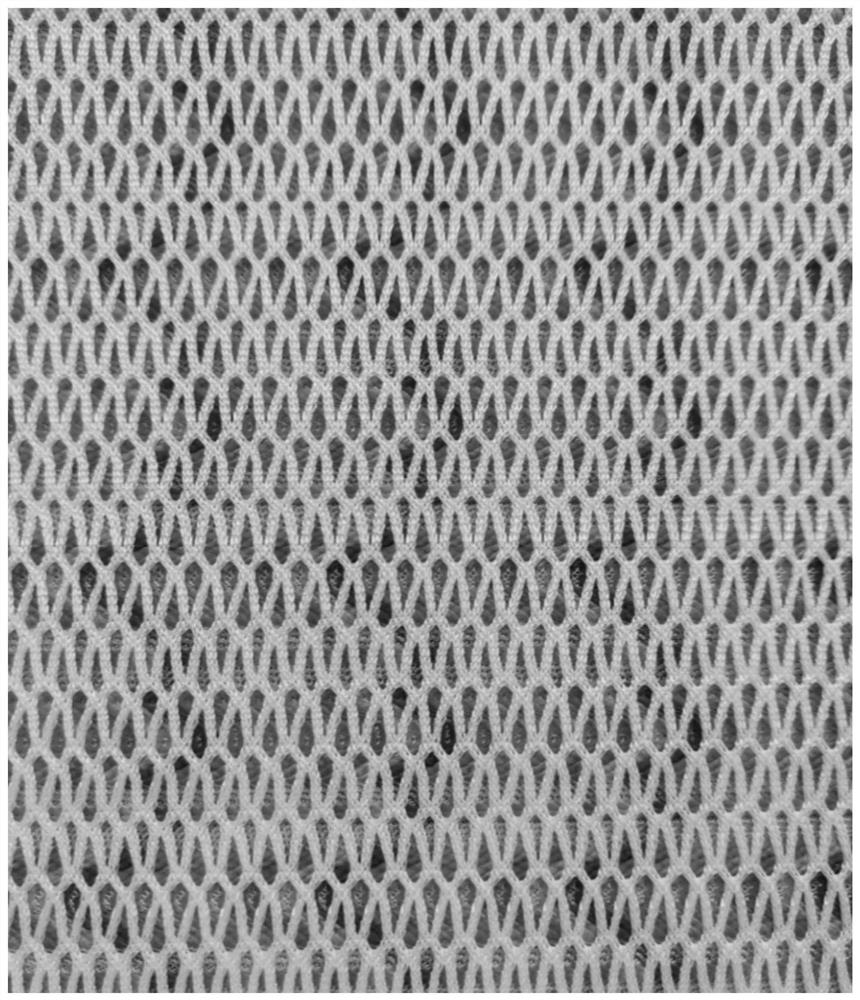

Embodiment 2

[0066] Method for making wavy jacquard velvet fabric mesh in warp knitting holes, face mesh layer 1:

[0067] GB1: Warping P-FDY150D / 96F semi-gloss yarn has 6 pan heads and 238 yarns in each pan head. The threading of GB1 yarn on the machine is one thread and one empty. The warp let-off amount of the gear is 750mm / lac GB1 running weft insertion weave 0-0 / 2-2 / / , GB1 polyester yarn content accounts for about 3.287%.

[0068] GB2: Warping P-FDYP-FDY300D / 96F semi-gloss yarn has 6 pan heads and 238 yarns in each pan head. GB2 yarns are threaded on the machine in the way of 2 threads and 2 holes, and the warp let-off amount of the gear is 2150mm / Lak, GB2 changes warp and satin weave 1-0 / 2-3 / (3-2 / 2-3)*2 / 4-5 / 3-2 / / , GB2 polyester yarn content accounts for about 18.847%.

[0069] GB3: Warping P-FDYP-FDY300D / 96F semi-gloss yarn with 6 pan heads and 238 yarns in each pan head. GB3 yarn is threaded on the machine in the way of 2 threads and 2 holes, and the warp let-off amount of the gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com