High-molecular water-soluble polymer residue soil dispersing agent

A water-soluble polymer and dispersant technology, applied in lubricating compositions, earth-moving drilling, mining equipment, etc., can solve the problems of large differences in the effect of dispersant solutions, affecting the normal progress of construction, increasing construction risks, etc. The effect of social benefit and economy, shortening the construction period, and reducing the frequency of opening positions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

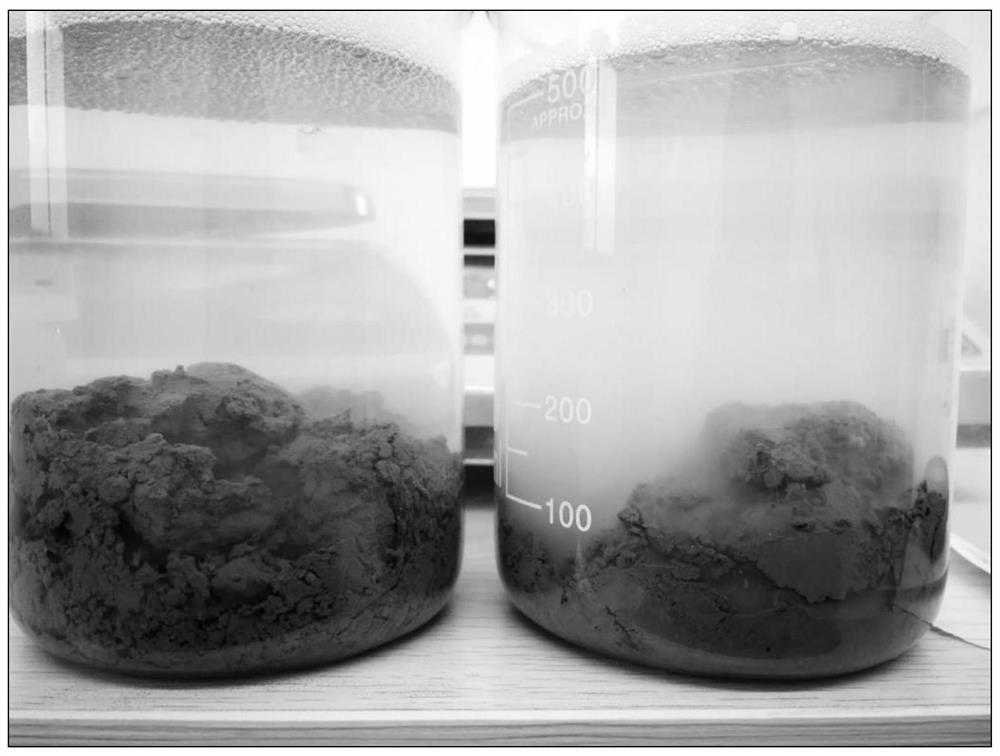

Image

Examples

Embodiment 1

[0023] The polymer water-soluble polymer slag dispersant of the present embodiment is made up of the composition of following mass percent: sodium polyacrylate 18%, polyethylene glycol 4%, fatty acid polyethylene glycol fat 3%, fatty alcohol polyoxyethylene ether 5%, N-methylpyrrolidone 5%, water 65%.

[0024] The preparation process of the polymer water-soluble polymer slag dispersant of this embodiment is as follows: 18g sodium polyacrylate is added to 40g water and stirred until completely dissolved to obtain a sodium polyacrylate solution, and 5g fatty alcohol polyoxyethylene ether is added to 5g Stir in the N-methylpyrrolidone until completely dissolved to obtain a fatty alcohol polyoxyethylene ether solution, then mix the sodium polyacrylate solution with the fatty alcohol polyoxyethylene ether solution, and then add 4g polyethylene glycol and 3g fatty acid polyethylene glycol Alcohol, and add 25g of water and stir evenly to obtain a mixed solution, which is filtered to ...

Embodiment 2

[0029] The polymer water-soluble polymer slag dispersant of the present embodiment is made up of the composition of following mass percent: sodium polyacrylate 21%, polyethylene glycol 4%, fatty acid polyethylene glycol fat 3%, fatty alcohol polyoxyethylene ether 6%, N-methylpyrrolidone 6%, water 60%.

[0030] The preparation process of the polymer water-soluble polymer slag dispersant of this embodiment is as follows: 21g sodium polyacrylate is added to 35g water and stirred until completely dissolved to obtain a sodium polyacrylate solution, and 6g fatty alcohol polyoxyethylene ether is added to 6g Stir in the N-methylpyrrolidone until completely dissolved to obtain a fatty alcohol polyoxyethylene ether solution, then mix the sodium polyacrylate solution with the fatty alcohol polyoxyethylene ether solution, and then add 4g polyethylene glycol and 3g fatty acid polyethylene glycol Alcohol, and add 25g of water and stir evenly to obtain a mixed solution, which is filtered to ...

Embodiment 3

[0035] The polymer water-soluble polymer slag dispersant of the present embodiment is made up of the composition of following mass percent: sodium polyacrylate 24%, polyethylene glycol 4%, fatty acid polyethylene glycol fat 3%, fatty alcohol polyoxyethylene ether 6%, N-methylpyrrolidone 6%, water 57%.

[0036] The preparation process of the polymer water-soluble polymer slag dispersant of this embodiment is as follows: 24g sodium polyacrylate is added to 35g water and stirred until completely dissolved to obtain a sodium polyacrylate solution, and 6g fatty alcohol polyoxyethylene ether is added to 6g Stir in the N-methylpyrrolidone until completely dissolved to obtain a fatty alcohol polyoxyethylene ether solution, then mix the sodium polyacrylate solution with the fatty alcohol polyoxyethylene ether solution, and then add 4g polyethylene glycol and 3g fatty acid polyethylene glycol Alcohol, and add 22g of water and stir evenly to obtain a mixed solution, which is filtered to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com