Lubricating grease and preparation method and application thereof

A technology of lubricating grease and dodecahydroxystearic acid, applied in the field of lubricating grease, can solve the problems such as the inability to fully meet the lubrication requirements of electric hammer cylinder, and achieve the effect of good anti-corrosion protection effect, good anti-oxidation performance and good anti-wear performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] This embodiment provides a lubricating grease of the present invention.

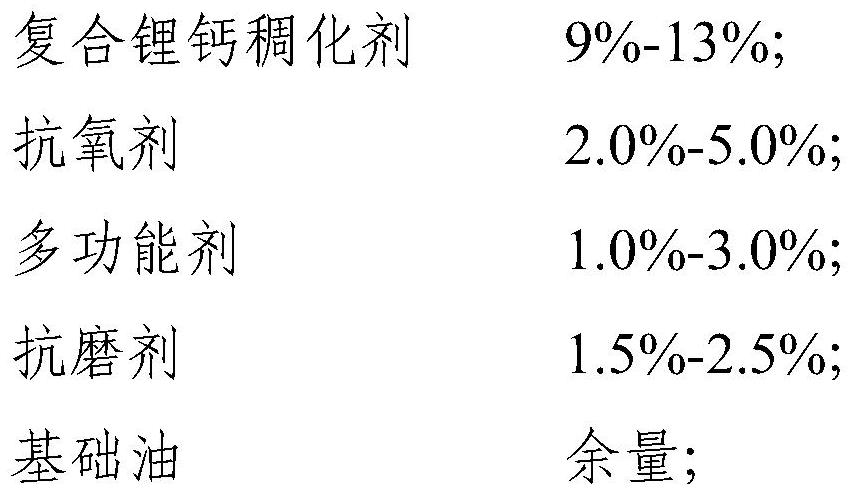

[0052] Concrete formula is by weight percentage (total amount is in 100%):

[0053]

[0054]

[0055] The complex lithium-calcium thickener is prepared from calcium hydroxide, lithium hydroxide, lauryl hydroxystearic acid and sebacic acid; the mass ratio of the calcium hydroxide to lithium hydroxide is 1:7.65; the dodecyl The mass ratio of hydroxystearic acid to the sebacic acid is 1:0.34.

[0056] The antioxidant is a mixture of GA-034 (purchased from Tianjin Lianlong New Material Co., Ltd.) and GA-032 (purchased from Tianjin Lianlong New Material Co., Ltd.) with a mass ratio of 3:1.

[0057] The base oil is a mixture of Dalian Petrochemical HVI650 (purchased from PetroChina Dalian Petrochemical Company), Mobil 500SN (purchased from Mobil Corporation), and INEOS PAO10 (purchased from INEOS Corporation) with a mass ratio of 4:4:2. Viscosity at 40°C is 101mm 2 / s.

[0058] The preparation...

Embodiment 2

[0061] This embodiment provides a lubricating grease of the present invention.

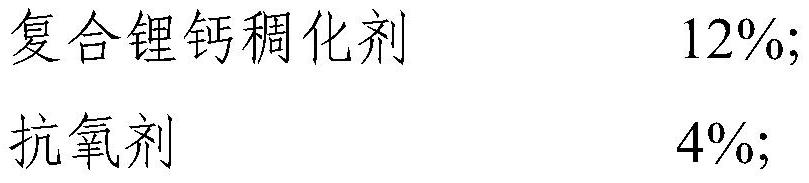

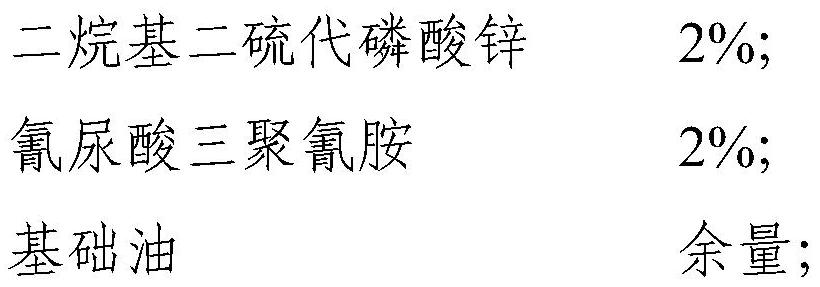

[0062] Concrete formula is by weight percentage (total amount is in 100%):

[0063]

[0064] The complex lithium-calcium thickener is prepared from calcium hydroxide, lithium hydroxide, lauryl hydroxystearic acid and sebacic acid; the mass ratio of the calcium hydroxide to lithium hydroxide is 1:7; the dodecyl The mass ratio of hydroxystearic acid to the sebacic acid is 1:0.3.

[0065] The antioxidant is a mixture of GA-034 (purchased from Tianjin Lianlong New Material Co., Ltd.) and GA-032 (purchased from Tianjin Lianlong New Material Co., Ltd.) with a mass ratio of 3:1.

[0066] The base oil is a mixture of Dalian Petrochemical HVI650 (purchased from PetroChina Dalian Petrochemical Company), Mobil 500SN (purchased from Mobil Corporation), and INEOS PAO10 (purchased from INEOS Corporation) with a mass ratio of 4:4:2. Viscosity at 40°C is 96mm 2 / s.

[0067] The preparation method is:

[0...

Embodiment 3

[0070] This embodiment provides a lubricating grease of the present invention.

[0071] Concrete formula is by weight percentage (total amount is in 100%):

[0072]

[0073] The complex lithium-calcium thickener is prepared from calcium hydroxide, lithium hydroxide, lauryl hydroxystearic acid and sebacic acid; the mass ratio of the calcium hydroxide to lithium hydroxide is 1:8; the dodecyl The mass ratio of hydroxystearic acid to the sebacic acid is 1:0.36.

[0074] The antioxidant is a mixture of GA-034 (purchased from Tianjin Lianlong New Material Co., Ltd.) and GA-032 (purchased from Tianjin Lianlong New Material Co., Ltd.) with a mass ratio of 3:1.

[0075] The base oil is a mixture of Dalian Petrochemical HVI650 (purchased from PetroChina Dalian Petrochemical Company), Mobil 500SN (purchased from Mobil Corporation), and INEOS PAO10 (purchased from INEOS Corporation) with a mass ratio of 4:4:2. Viscosity at 40°C is 105mm 2 / s.

[0076] The preparation method is:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com