Spinning roller cart for spinning workshop

A technology of textile rollers and carts, applied in the fields of textile machinery and logistics machinery, can solve the problems of low labor intensity of workers, limited number of textile rollers, and limited transfer capacity, etc. The effect of strong conveying ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

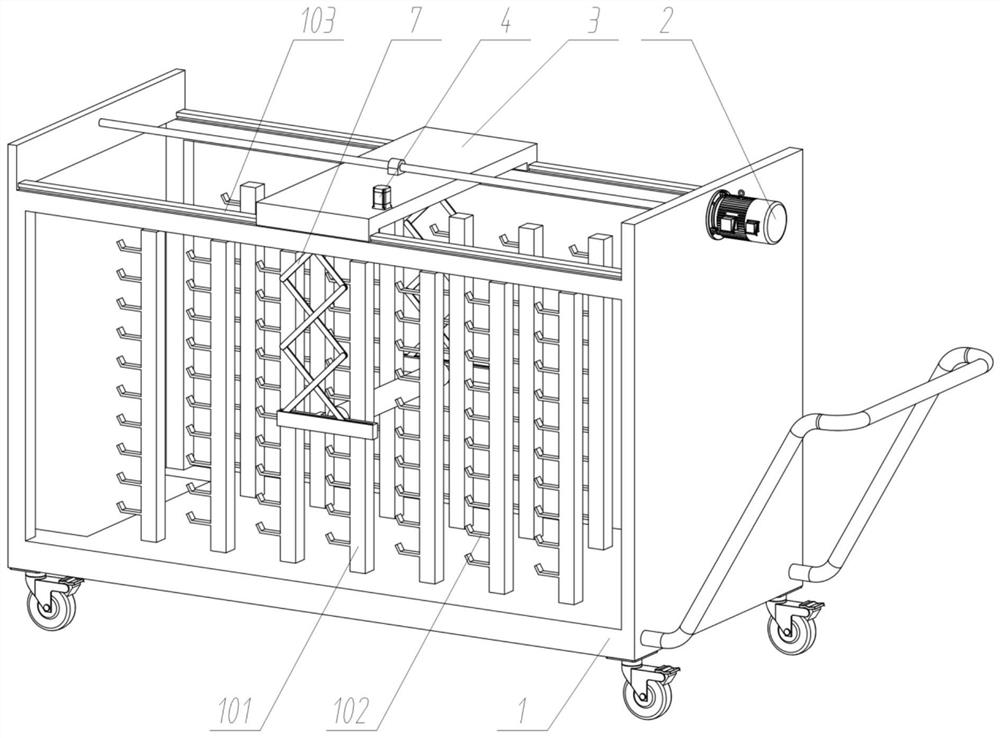

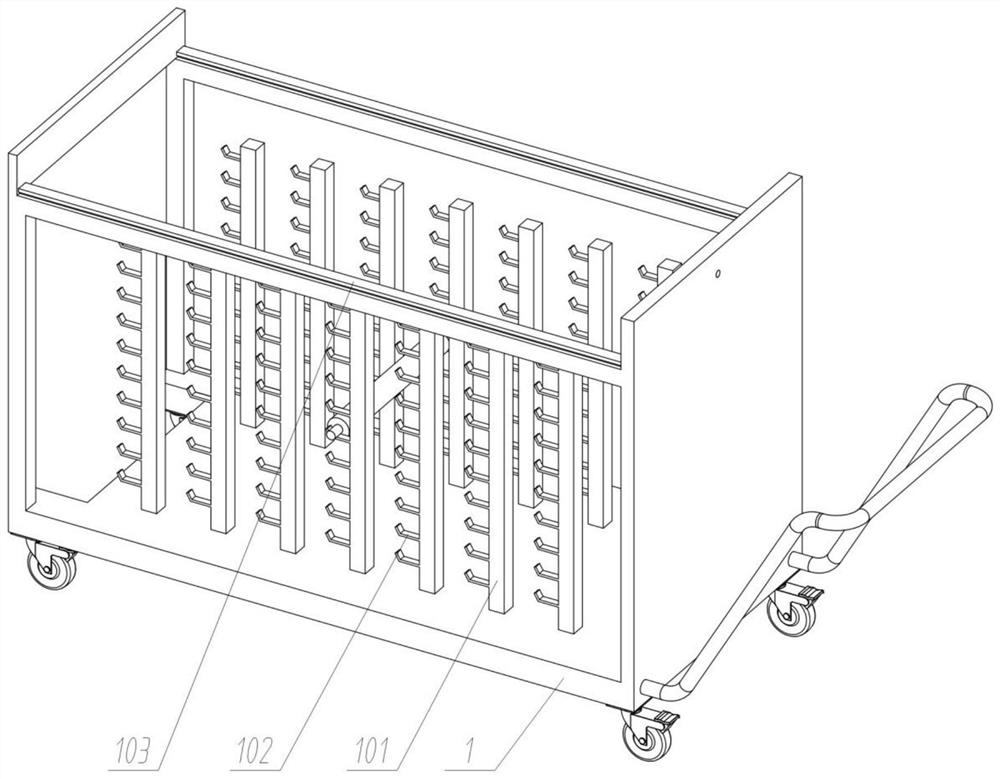

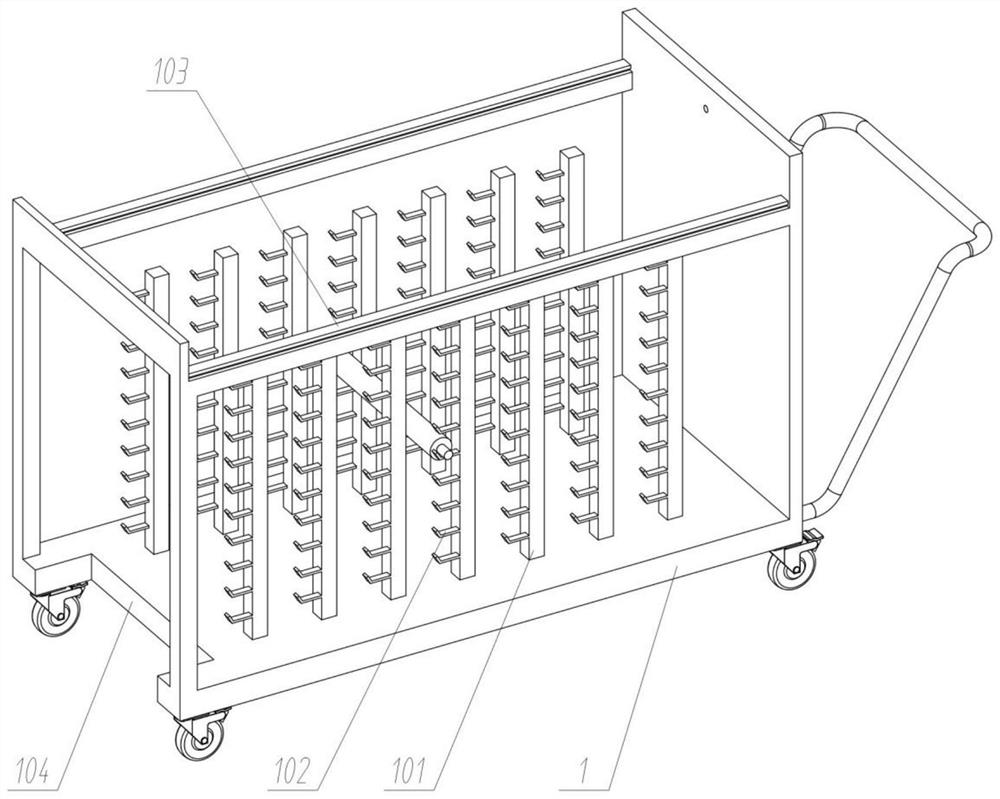

[0029] see Figure 1 to Figure 8 , an embodiment provided by the present invention: a textile roller cart for a textile workshop, comprising a cart main body 1; A group of sliding carriages 3 is connected; a group of lifting drive parts 4 is fixedly connected to the top of the sliding carriage 3; A group of rear lifting driving screw 6 is connected in rotation; a group of lifting blocks 8 are connected with three pairs of lifting connecting rods 7 before and after the sliding carriage 3 .

[0030] Further, the cart main body 1 also includes a material storage column 101 and a material storage hook 102. Seven groups of material storage columns 101 are evenly arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com