Powder bed synchronous heating and melting additive manufacturing method

A technology of additive manufacturing and powder bed, which is applied in the field of additive manufacturing, can solve the problems affecting the surface finish of parts, the failure of inner hole forming, and the difficulty of removing inner hole powder, so as to avoid large fluctuations, reduce thermal stress, and high heating efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

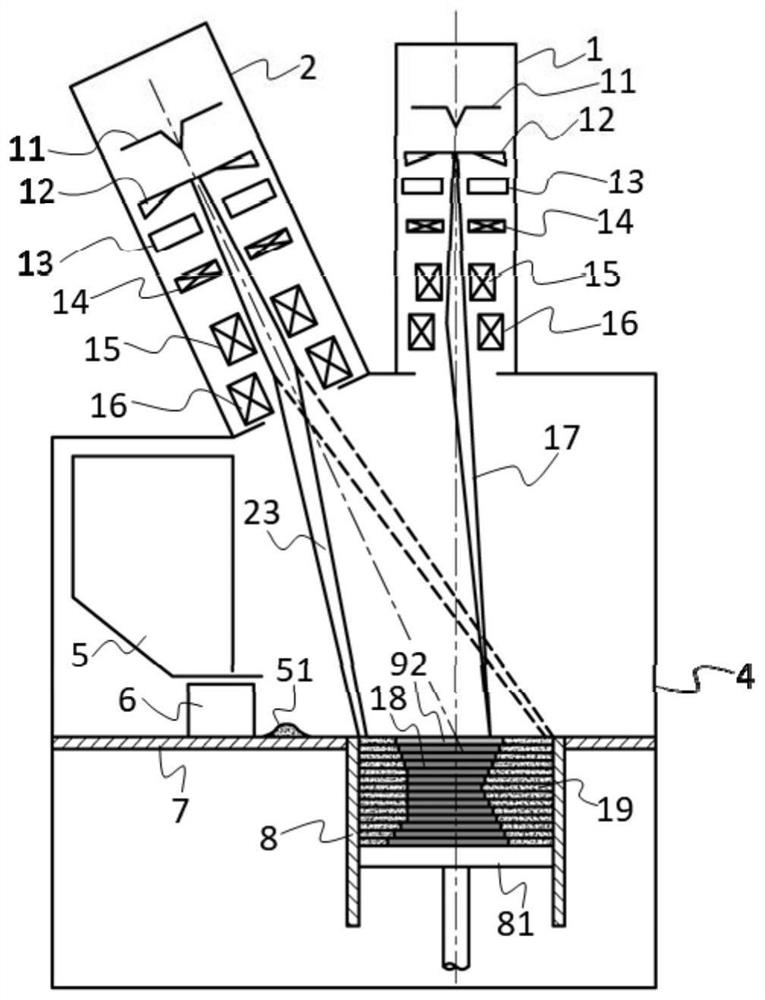

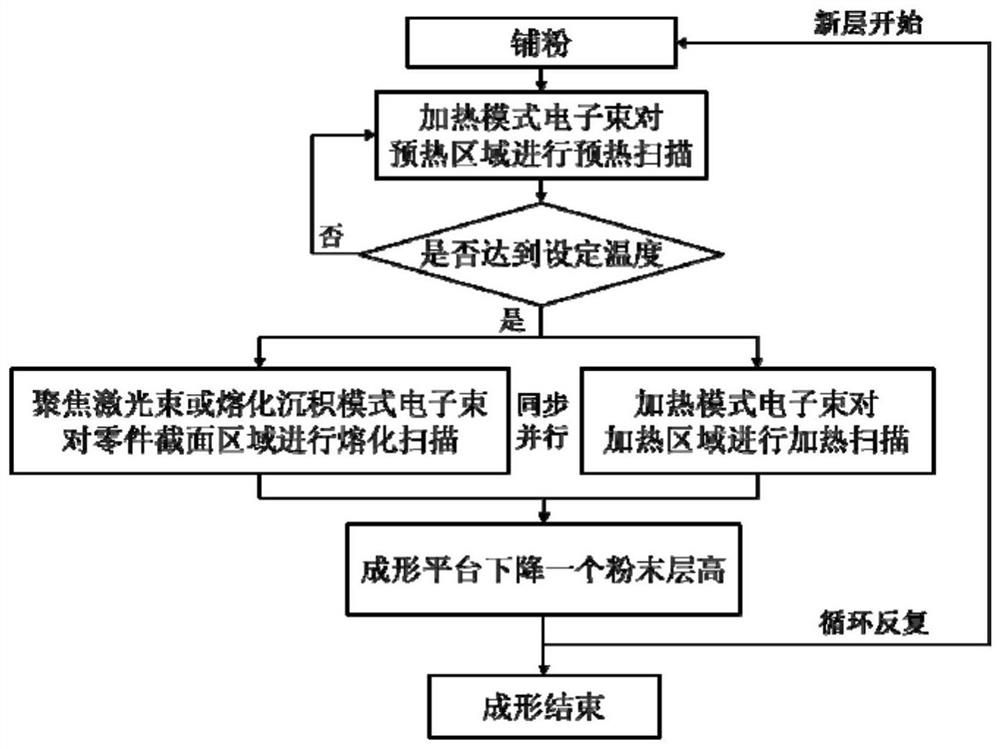

[0064] Such as figure 1 The powder bed synchronous heating and melting process and device shown. Including: vacuum forming chamber 4, working platform 7, forming cylinder 8, piston type lifting device 81, powder feeder 5, powder laying device 6, electron beam emission gathering scanning device 2 for emitting electron beam in heating mode, electron beam emission in melting deposition mode The electron beam emission of the beam focuses the scanning device 1 and a control computer (not shown) as a controller.

[0065] The electron beam emitting and focusing scanning device 2 includes a cathode 11 for generating an electron beam 23 , a grid 12 , an anode 13 , a focusing coil 14 , an astigmatism elimination coil 15 , and a deflection coil 16 . Electron beam emission focusing scanning device 2 emits heating mode electron beam 23 for preheating and heating scanning of the powder bed in the preheating area and heating area, electron beam emitting focusing scanning device 1 emits melt...

Embodiment 2

[0069] Such as Figure 5 The powder bed synchronous heating and melting process and device shown include: vacuum forming chamber 4, working platform 7, forming cylinder 8, piston type lifting device 81, powder feeder 5, powder laying device 6, anti-evaporation device 36, electronic A beam emitting focusing scanning device 2, a laser beam emitting focusing scanning device 3, and a control computer (not shown) as a controller.

[0070] The laser beam emitting and gathering scanning device 3 includes a laser light source 31 that generates laser light and a focusing scanning device 32 connected to the laser light source 31, generates a laser beam 37 that passes through the lead glass 33 and enters the vacuum forming chamber 4, and scans the area of the formed part for sintering and melting powder.

[0071] The vacuum forming chamber 4 provides a vacuum environment for the selective melting process, and a working platform 7 is arranged horizontally in the middle. The powder fee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com